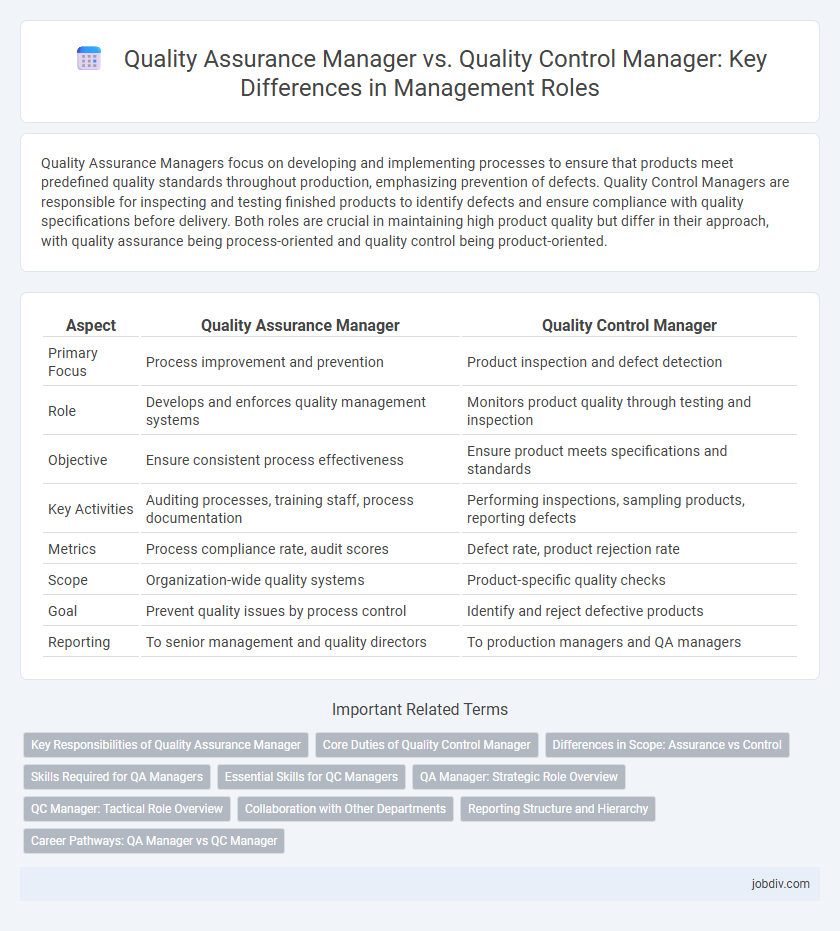

Quality Assurance Managers focus on developing and implementing processes to ensure that products meet predefined quality standards throughout production, emphasizing prevention of defects. Quality Control Managers are responsible for inspecting and testing finished products to identify defects and ensure compliance with quality specifications before delivery. Both roles are crucial in maintaining high product quality but differ in their approach, with quality assurance being process-oriented and quality control being product-oriented.

Table of Comparison

| Aspect | Quality Assurance Manager | Quality Control Manager |

|---|---|---|

| Primary Focus | Process improvement and prevention | Product inspection and defect detection |

| Role | Develops and enforces quality management systems | Monitors product quality through testing and inspection |

| Objective | Ensure consistent process effectiveness | Ensure product meets specifications and standards |

| Key Activities | Auditing processes, training staff, process documentation | Performing inspections, sampling products, reporting defects |

| Metrics | Process compliance rate, audit scores | Defect rate, product rejection rate |

| Scope | Organization-wide quality systems | Product-specific quality checks |

| Goal | Prevent quality issues by process control | Identify and reject defective products |

| Reporting | To senior management and quality directors | To production managers and QA managers |

Key Responsibilities of Quality Assurance Manager

The Quality Assurance Manager oversees the development and implementation of comprehensive quality management systems, ensuring compliance with industry standards and regulatory requirements. They lead process improvement initiatives, conduct audits, and collaborate with cross-functional teams to prevent defects and enhance product reliability. Their key responsibilities include establishing quality policies, training staff on quality procedures, and driving continuous improvement to maintain customer satisfaction and operational excellence.

Core Duties of Quality Control Manager

Quality Control Managers oversee the inspection processes, ensuring products meet specified standards through systematic testing and measurement. They design quality control protocols, manage defect detection, and coordinate corrective actions to maintain compliance with regulatory and company standards. Their role is crucial in monitoring production quality and minimizing product defects to enhance customer satisfaction and operational efficiency.

Differences in Scope: Assurance vs Control

Quality Assurance Managers focus on establishing and maintaining processes to prevent defects, ensuring overall system quality through proactive planning and process improvement. Quality Control Managers concentrate on detecting and correcting defects in products or services through inspection and testing, applying reactive measures to maintain product standards. The scope of assurance emphasizes process optimization, while control centers on product verification and defect identification.

Skills Required for QA Managers

Quality Assurance Managers require strong leadership skills, expertise in process improvement methodologies like Six Sigma, and proficiency in risk management to ensure product quality throughout the development lifecycle. They must excel in communication and analytical thinking to implement quality systems and collaborate across departments effectively. Technical knowledge of industry standards and regulatory compliance is essential for driving continuous quality enhancement and meeting organizational goals.

Essential Skills for QC Managers

Quality Control Managers require strong analytical skills to interpret data accurately and identify defects efficiently, ensuring product standards meet regulatory requirements. Proficiency in statistical process control and root cause analysis enables them to implement effective corrective actions that enhance production quality. Effective communication and leadership skills are also essential for coordinating teams and enforcing compliance with quality control protocols.

QA Manager: Strategic Role Overview

A Quality Assurance Manager drives organizational excellence by developing and implementing strategic quality management systems aligned with business goals, ensuring compliance with industry standards such as ISO 9001. Responsibilities include overseeing process improvements, risk management, and cross-functional collaboration to enhance product reliability and customer satisfaction. This strategic role focuses on preventing defects through proactive planning rather than just identifying issues, distinguishing it from the more operational Quality Control Manager position.

QC Manager: Tactical Role Overview

A Quality Control (QC) Manager oversees the implementation of inspection procedures and testing protocols to ensure products meet predefined quality standards. They manage tactical activities such as defect detection, non-conformity analysis, and corrective action coordination on the production floor. Emphasis on real-time monitoring and compliance verification distinguishes the QC Manager's role from strategic planning, focusing on operational execution and immediate quality assurance.

Collaboration with Other Departments

Quality Assurance Managers collaborate closely with product development and process engineering teams to establish standards that prevent defects and ensure product reliability. Quality Control Managers work alongside manufacturing and inspection teams to monitor outputs and detect deviations from quality specifications. Both roles require effective communication with supply chain and customer service departments to maintain consistent product quality and address issues promptly.

Reporting Structure and Hierarchy

A Quality Assurance Manager typically reports to the Director of Quality or Operations, overseeing the development and implementation of quality systems across departments, while a Quality Control Manager reports to the Quality Assurance Manager or Production Manager, focusing on monitoring and inspecting specific product outputs. The hierarchical structure places the Quality Assurance Manager at a higher level, responsible for strategic planning and compliance, whereas the Quality Control Manager operates with a more tactical role within a clearly defined functional team. This reporting structure ensures alignment between quality policies and operational execution, maintaining organizational quality standards.

Career Pathways: QA Manager vs QC Manager

Quality Assurance Managers typically advance from roles in process improvement or auditing, focusing on developing and implementing comprehensive quality management systems to ensure compliance and prevent defects. Quality Control Managers often rise through hands-on inspection or lab technician positions, emphasizing product testing and defect identification to maintain product standards. Career progression for QA Managers usually leads to higher strategic roles like Director of Quality or Operations, while QC Managers may transition into supervisory or technical specialist positions within manufacturing or production environments.

Quality Assurance Manager vs Quality Control Manager Infographic

jobdiv.com

jobdiv.com