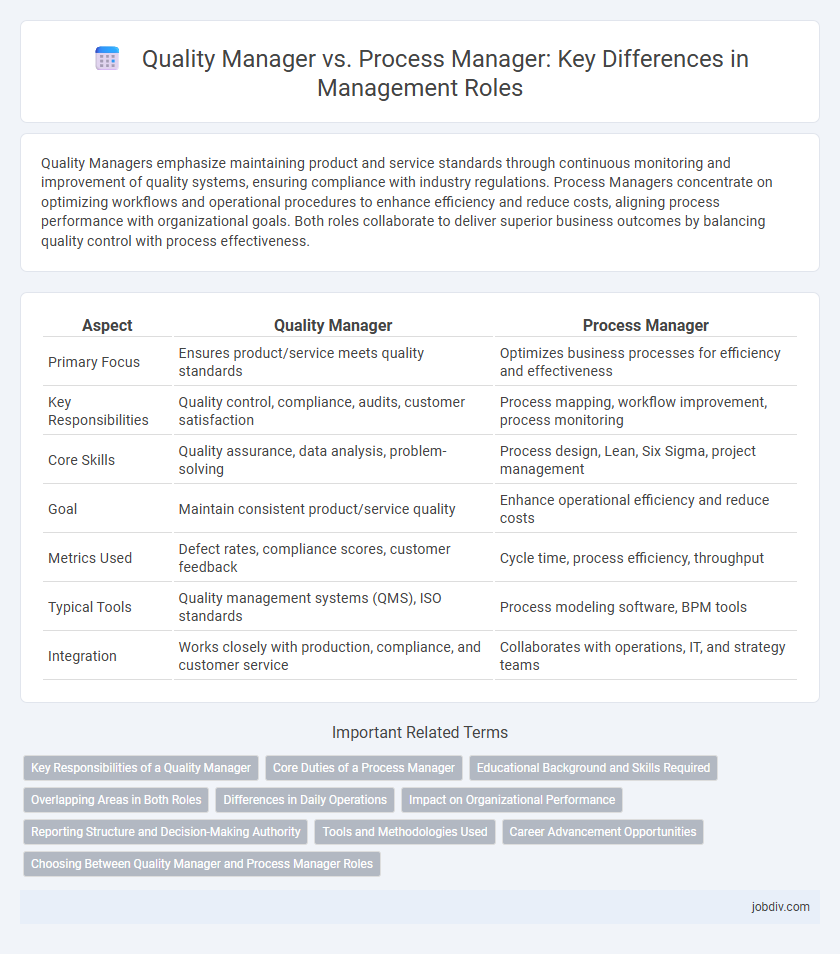

Quality Managers emphasize maintaining product and service standards through continuous monitoring and improvement of quality systems, ensuring compliance with industry regulations. Process Managers concentrate on optimizing workflows and operational procedures to enhance efficiency and reduce costs, aligning process performance with organizational goals. Both roles collaborate to deliver superior business outcomes by balancing quality control with process effectiveness.

Table of Comparison

| Aspect | Quality Manager | Process Manager |

|---|---|---|

| Primary Focus | Ensures product/service meets quality standards | Optimizes business processes for efficiency and effectiveness |

| Key Responsibilities | Quality control, compliance, audits, customer satisfaction | Process mapping, workflow improvement, process monitoring |

| Core Skills | Quality assurance, data analysis, problem-solving | Process design, Lean, Six Sigma, project management |

| Goal | Maintain consistent product/service quality | Enhance operational efficiency and reduce costs |

| Metrics Used | Defect rates, compliance scores, customer feedback | Cycle time, process efficiency, throughput |

| Typical Tools | Quality management systems (QMS), ISO standards | Process modeling software, BPM tools |

| Integration | Works closely with production, compliance, and customer service | Collaborates with operations, IT, and strategy teams |

Key Responsibilities of a Quality Manager

A Quality Manager oversees the development and implementation of quality control systems to ensure products or services meet established standards and regulatory requirements. They conduct audits, manage compliance processes, and lead continuous improvement initiatives to enhance customer satisfaction and operational efficiency. Collaboration with cross-functional teams enables them to identify quality issues and implement corrective actions effectively.

Core Duties of a Process Manager

A Process Manager is responsible for designing, implementing, and optimizing organizational workflows to enhance efficiency and productivity. They analyze existing processes, identify bottlenecks, and apply continuous improvement methodologies such as Six Sigma or Lean to drive operational excellence. Their core duties include process mapping, performance measurement, cross-functional coordination, and ensuring compliance with industry standards to support business objectives.

Educational Background and Skills Required

Quality Managers typically hold degrees in Quality Management, Engineering, or Business Administration, emphasizing expertise in quality control, regulatory compliance, and risk management. Process Managers often have educational backgrounds in Industrial Engineering, Operations Management, or Business Process Management, with skills focused on process optimization, workflow analysis, and Lean Six Sigma methodologies. Both roles require strong analytical abilities, leadership skills, and proficiency in data-driven decision-making to enhance organizational efficiency and product quality.

Overlapping Areas in Both Roles

Quality Managers and Process Managers both play critical roles in enhancing operational efficiency and product standards, with overlapping responsibilities in process optimization, compliance monitoring, and performance measurement. They collaborate on implementing quality control systems and continuous improvement initiatives, ensuring that organizational processes meet regulatory requirements and customer expectations. Both roles require strong analytical skills and a deep understanding of operational workflows to align quality metrics with process efficiency.

Differences in Daily Operations

A Quality Manager primarily focuses on monitoring product standards, auditing processes, and ensuring compliance with industry regulations to maintain high-quality outputs. In contrast, a Process Manager designs, implements, and optimizes workflows to enhance operational efficiency and reduce bottlenecks within the production cycle. While Quality Managers emphasize defect prevention and quality control metrics, Process Managers concentrate on streamlining procedures and improving overall system performance.

Impact on Organizational Performance

Quality Managers enhance organizational performance by implementing rigorous quality control systems that minimize defects and ensure customer satisfaction, leading to higher product reliability and brand reputation. Process Managers optimize workflows and operational efficiencies by analyzing and refining processes, resulting in reduced costs, faster production cycles, and improved resource allocation. Both roles are critical, with Quality Managers driving product excellence and Process Managers streamlining operations, collectively boosting overall organizational effectiveness and competitive advantage.

Reporting Structure and Decision-Making Authority

A Quality Manager typically reports to the Operations or Quality Director, holding authority over compliance and product standards enforcement to ensure quality objectives align with corporate goals. A Process Manager often reports to the Plant Manager or Continuous Improvement Director, with decision-making authority centered on optimizing workflows and process efficiencies across departments. Both roles collaborate closely, but the Quality Manager emphasizes regulatory adherence while the Process Manager focuses on operational improvements.

Tools and Methodologies Used

Quality Managers primarily utilize tools like Six Sigma, Total Quality Management (TQM), and Statistical Process Control (SPC) to monitor and improve product and service quality. Process Managers focus on methodologies such as Lean Management, Business Process Model and Notation (BPMN), and workflow automation software to optimize operational efficiency and streamline processes. Both roles leverage data analytics platforms to support decision-making and drive continuous improvement across organizational functions.

Career Advancement Opportunities

Quality Managers often advance by specializing in regulatory compliance, risk management, and quality assurance leadership roles, leveraging certifications like Six Sigma or ASQ to boost career growth. Process Managers expand their career prospects through expertise in process optimization, operational efficiency, and lean management techniques, frequently moving into roles such as operations director or continuous improvement manager. Both career paths benefit greatly from strong analytical skills and cross-functional project leadership experience, increasing opportunities in senior management and executive positions.

Choosing Between Quality Manager and Process Manager Roles

Selecting between a Quality Manager and a Process Manager depends on organizational priorities such as product excellence or operational efficiency. A Quality Manager focuses on ensuring products meet regulatory standards and customer expectations through quality control and assurance methodologies. In contrast, a Process Manager optimizes workflows and resource allocation to enhance productivity and reduce bottlenecks across business processes.

Quality Manager vs Process Manager Infographic

jobdiv.com

jobdiv.com