Maintenance Mechanics specialize in repairing and maintaining machinery to ensure operational efficiency, while Facilities Technicians manage building systems like HVAC, electrical, and plumbing to maintain a safe environment. Both roles are crucial for minimizing downtime and extending the lifespan of equipment and infrastructure. Understanding the specific duties of each helps businesses allocate resources effectively for preventive maintenance and repairs.

Table of Comparison

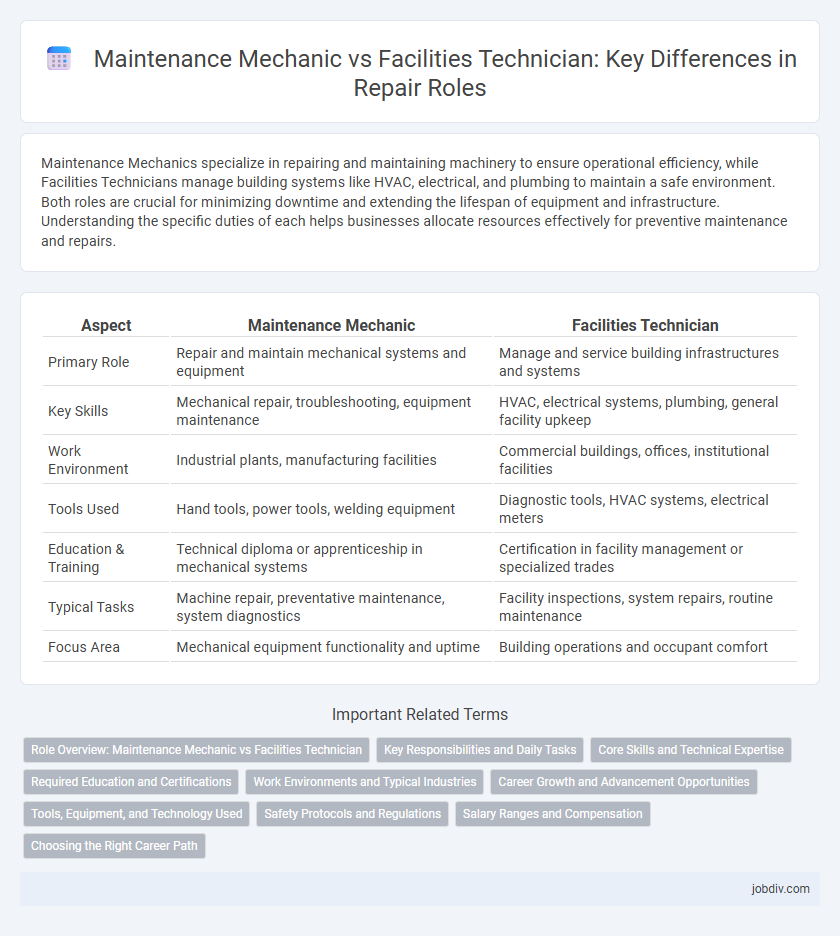

| Aspect | Maintenance Mechanic | Facilities Technician |

|---|---|---|

| Primary Role | Repair and maintain mechanical systems and equipment | Manage and service building infrastructures and systems |

| Key Skills | Mechanical repair, troubleshooting, equipment maintenance | HVAC, electrical systems, plumbing, general facility upkeep |

| Work Environment | Industrial plants, manufacturing facilities | Commercial buildings, offices, institutional facilities |

| Tools Used | Hand tools, power tools, welding equipment | Diagnostic tools, HVAC systems, electrical meters |

| Education & Training | Technical diploma or apprenticeship in mechanical systems | Certification in facility management or specialized trades |

| Typical Tasks | Machine repair, preventative maintenance, system diagnostics | Facility inspections, system repairs, routine maintenance |

| Focus Area | Mechanical equipment functionality and uptime | Building operations and occupant comfort |

Role Overview: Maintenance Mechanic vs Facilities Technician

Maintenance Mechanics specialize in diagnosing, repairing, and maintaining mechanical systems such as HVAC, plumbing, and machinery to ensure operational efficiency. Facilities Technicians perform broader tasks including electrical repairs, building inspections, and routine maintenance to support overall facility functionality. Both roles require technical skills but differ in their focus; Maintenance Mechanics concentrate on mechanical components, while Facilities Technicians address a wider range of building systems.

Key Responsibilities and Daily Tasks

Maintenance Mechanics specialize in troubleshooting, repairing, and maintaining machinery and mechanical equipment, ensuring optimal operational efficiency in industrial settings. Facilities Technicians focus on the upkeep of building systems such as HVAC, electrical, plumbing, and general infrastructure to maintain a safe and functional environment. Both roles require routine inspections, preventive maintenance, and quick response to repair requests to minimize downtime and extend the lifespan of assets.

Core Skills and Technical Expertise

Maintenance Mechanics specialize in diagnosing and repairing mechanical systems, using skills in hydraulics, pneumatics, and machinery troubleshooting to ensure optimal equipment performance. Facilities Technicians possess broader technical expertise, including electrical, HVAC, plumbing, and building system maintenance, enabling them to manage and repair diverse infrastructure components. Both roles require proficiency in safety protocols and preventive maintenance, but Maintenance Mechanics focus more on machinery-specific tasks while Facilities Technicians handle comprehensive facility operations.

Required Education and Certifications

Maintenance Mechanics typically require a high school diploma or equivalent, with additional vocational training or certification in mechanical systems, electrical systems, or hydraulics enhancing job prospects. Facilities Technicians often need similar educational backgrounds but prioritize certifications in HVAC, electrical maintenance, or building management systems to handle diverse facility operations. Both roles benefit from OSHA safety certifications and industry-specific credentials such as EPA Section 608 for HVAC or NCCER certification for maintenance skills.

Work Environments and Typical Industries

Maintenance Mechanics typically work in manufacturing plants, automotive industries, and heavy machinery environments where they focus on repairing and maintaining mechanical equipment. Facilities Technicians are commonly employed in commercial buildings, hospitals, educational institutions, and corporate offices, ensuring the operational integrity of HVAC, plumbing, and electrical systems. Both roles demand adaptability to various work environments, but Maintenance Mechanics often deal with industrial settings, whereas Facilities Technicians specialize in managing building infrastructure.

Career Growth and Advancement Opportunities

Maintenance Mechanics often specialize in repairing and maintaining mechanical systems, offering clear career advancement through certifications in HVAC, hydraulics, or industrial machinery, which can lead to supervisory or technical specialist roles. Facilities Technicians work on a broader range of building systems, including electrical, plumbing, and HVAC, providing opportunities to advance into facilities management or project coordination roles by gaining cross-disciplinary expertise. Both careers offer strong growth potential, but Facilities Technicians may benefit from diverse skill sets that align with leadership positions in facility operations.

Tools, Equipment, and Technology Used

Maintenance Mechanics primarily use hand tools, power tools, diagnostic instruments, and mechanical equipment to repair and maintain machinery and systems. Facilities Technicians rely on building systems technologies such as HVAC controls, electrical testing devices, plumbing tools, and computerized maintenance management systems (CMMS) to ensure operational efficiency. Advanced technology integration, including automated monitoring tools and smart sensors, is increasingly common in both roles for predictive maintenance and real-time troubleshooting.

Safety Protocols and Regulations

Maintenance mechanics adhere strictly to OSHA safety protocols and machinery-specific regulations to prevent workplace accidents and ensure equipment longevity. Facilities technicians follow comprehensive safety standards including NFPA codes and building compliance regulations to manage electrical, HVAC, and plumbing systems safely. Both roles require ongoing training in hazard communication, lockout/tagout procedures, and emergency response to maintain a secure working environment.

Salary Ranges and Compensation

Maintenance mechanics typically earn between $40,000 and $65,000 annually, with salaries influenced by experience and industry specialization. Facilities technicians often have a salary range of $35,000 to $60,000, depending on technical skills and geographic location. Compensation packages for both roles may include benefits such as health insurance, overtime pay, and performance bonuses, impacting total earnings.

Choosing the Right Career Path

Maintenance mechanics specialize in troubleshooting, repairing, and maintaining mechanical systems such as engines, HVAC units, and manufacturing equipment, requiring strong technical skills and hands-on experience with machinery. Facilities technicians focus on the overall upkeep of buildings, managing electrical, plumbing, and safety systems to ensure operational efficiency and compliance with regulations. Choosing between these careers depends on your interest in working with mechanical systems versus broader facility management responsibilities, career growth opportunities, and desired work environments.

Maintenance Mechanic vs Facilities Technician Infographic

jobdiv.com

jobdiv.com