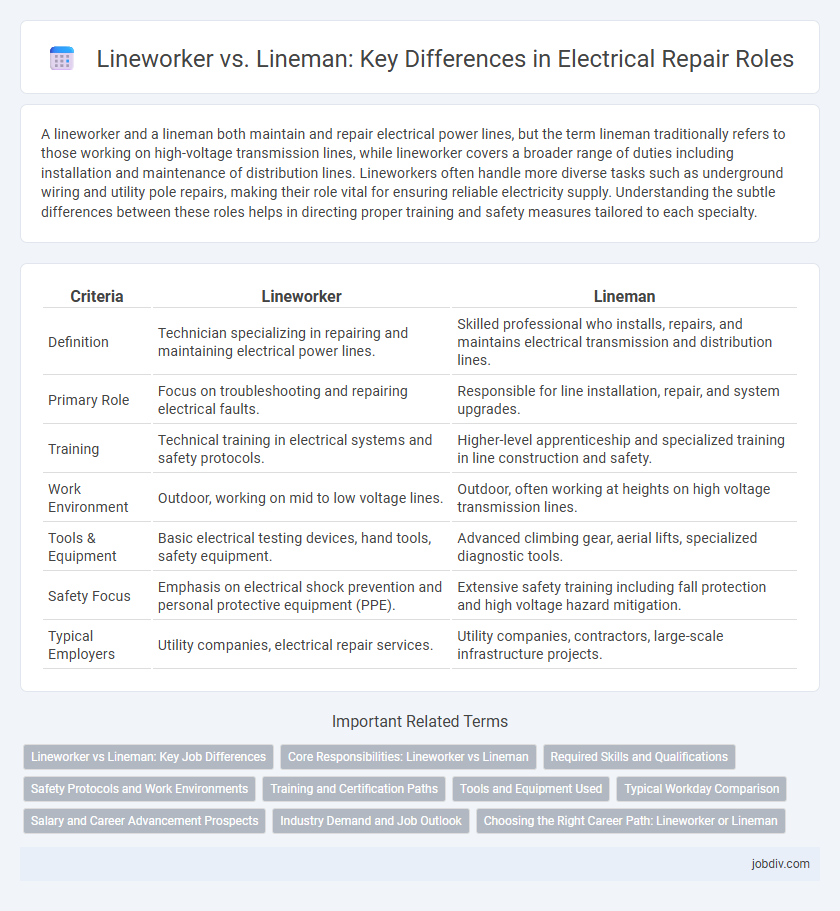

A lineworker and a lineman both maintain and repair electrical power lines, but the term lineman traditionally refers to those working on high-voltage transmission lines, while lineworker covers a broader range of duties including installation and maintenance of distribution lines. Lineworkers often handle more diverse tasks such as underground wiring and utility pole repairs, making their role vital for ensuring reliable electricity supply. Understanding the subtle differences between these roles helps in directing proper training and safety measures tailored to each specialty.

Table of Comparison

| Criteria | Lineworker | Lineman |

|---|---|---|

| Definition | Technician specializing in repairing and maintaining electrical power lines. | Skilled professional who installs, repairs, and maintains electrical transmission and distribution lines. |

| Primary Role | Focus on troubleshooting and repairing electrical faults. | Responsible for line installation, repair, and system upgrades. |

| Training | Technical training in electrical systems and safety protocols. | Higher-level apprenticeship and specialized training in line construction and safety. |

| Work Environment | Outdoor, working on mid to low voltage lines. | Outdoor, often working at heights on high voltage transmission lines. |

| Tools & Equipment | Basic electrical testing devices, hand tools, safety equipment. | Advanced climbing gear, aerial lifts, specialized diagnostic tools. |

| Safety Focus | Emphasis on electrical shock prevention and personal protective equipment (PPE). | Extensive safety training including fall protection and high voltage hazard mitigation. |

| Typical Employers | Utility companies, electrical repair services. | Utility companies, contractors, large-scale infrastructure projects. |

Lineworker vs Lineman: Key Job Differences

Lineworker and lineman are often used interchangeably but can have distinct job responsibilities depending on the region or employer. Linemen typically focus on installing, maintaining, and repairing high-voltage power lines and electrical distribution systems. Lineworkers may encompass a broader range of duties including working on telecommunications lines and smaller-scale utility systems, emphasizing versatility in field repair tasks.

Core Responsibilities: Lineworker vs Lineman

Lineworkers specialize in installing, maintaining, and repairing electrical power systems, ensuring consistent energy flow and safety compliance. Linemen often perform similar duties but may focus more on operating heavy equipment and managing high-voltage transmission lines. Their core responsibilities overlap in electrical infrastructure upkeep, yet lineworkers emphasize hands-on repairs while linemen handle broader system operations.

Required Skills and Qualifications

Lineworkers require specialized training in electrical systems, safety protocols, and physical stamina to work on power lines in various weather conditions. Linemen typically need certifications such as OSHA safety standards and climbing qualifications, alongside experience in troubleshooting and repairing electrical infrastructure. Both roles demand strong problem-solving skills, manual dexterity, and the ability to work at heights to ensure reliable utility service restoration.

Safety Protocols and Work Environments

Lineworkers and linemen both perform essential duties in electrical line maintenance but differ slightly in safety protocols and work environments. Lineworkers adhere to stringent safety protocols including the use of insulated gloves, hard hats, and fall protection gear to mitigate risks when working on high-voltage power lines, often in varied and harsh outdoor conditions. Linemen, typically involved in both installation and repair, must also follow strict safety standards, emphasizing proper lockout/tagout procedures and environmental hazard assessments to ensure safe operation in urban and rural settings.

Training and Certification Paths

Lineworkers and linemen undergo rigorous training programs focused on electrical safety, power distribution, and equipment maintenance, often including both classroom instruction and hands-on field experience. Certification paths typically involve completing apprenticeships, passing OSHA safety courses, and obtaining industry-recognized credentials such as the National Center for Construction Education and Research (NCCER) lineman certification. Continuous education and periodic recertification are essential to stay updated with evolving safety standards and technological advancements in the utility repair sector.

Tools and Equipment Used

Lineworkers and linemen both use specialized tools and equipment designed for electrical repair and maintenance, but lineworkers often handle advanced technology such as insulated rubber gloves, hot sticks, and bucket trucks to work safely on live power lines. Linemen typically rely on climbing gear, lineman pliers, wire cutters, and grounding sets for hands-on, physical repair tasks on power poles. Both roles require the use of voltage testers, safety harnesses, and protective helmets to ensure compliance with safety standards during electrical line repairs.

Typical Workday Comparison

Lineworkers typically start their day with equipment checks and safety briefings before heading to job sites to install, maintain, or repair electrical power lines. Linemen focus more on physical tasks such as climbing poles, handling wires, and troubleshooting outages to restore power during emergencies. Both roles demand rigorous safety measures and teamwork, but lineworkers often balance technical diagnostics with hands-on repairs throughout a typical workday.

Salary and Career Advancement Prospects

Lineworker and lineman roles often overlap, but lineworkers typically earn a median salary of around $70,000 annually, while linemen can command higher wages near $77,000 due to specialized skills. Career advancement prospects for lineworkers include climbing to supervisory positions or specializing in areas like fiber optics, whereas linemen may progress to electrical line supervisors or project managers. Both fields offer strong union support and opportunities for overtime pay, contributing to overall compensation growth and career stability in the repair and maintenance sector.

Industry Demand and Job Outlook

Lineworker and lineman roles in the electrical repair industry show increasing demand due to infrastructure upgrades and renewable energy expansion. The U.S. Bureau of Labor Statistics projects a 5% growth rate for electrical power-line installers and repairers through 2031, reflecting steady job opportunities. Skilled lineworkers specializing in high-voltage systems experience higher employability and competitive salaries.

Choosing the Right Career Path: Lineworker or Lineman

Choosing between a lineworker and a lineman career depends on the specific job focus, skills, and certifications required. Lineworkers typically handle the installation and maintenance of electrical power systems, often requiring climbing skills and safety training, while linemen may engage in broader electrical work, including troubleshooting and repair. Understanding the distinct responsibilities and physical demands of each role helps in making an informed decision aligned with career goals in the electrical repair industry.

Lineworker vs Lineman Infographic

jobdiv.com

jobdiv.com