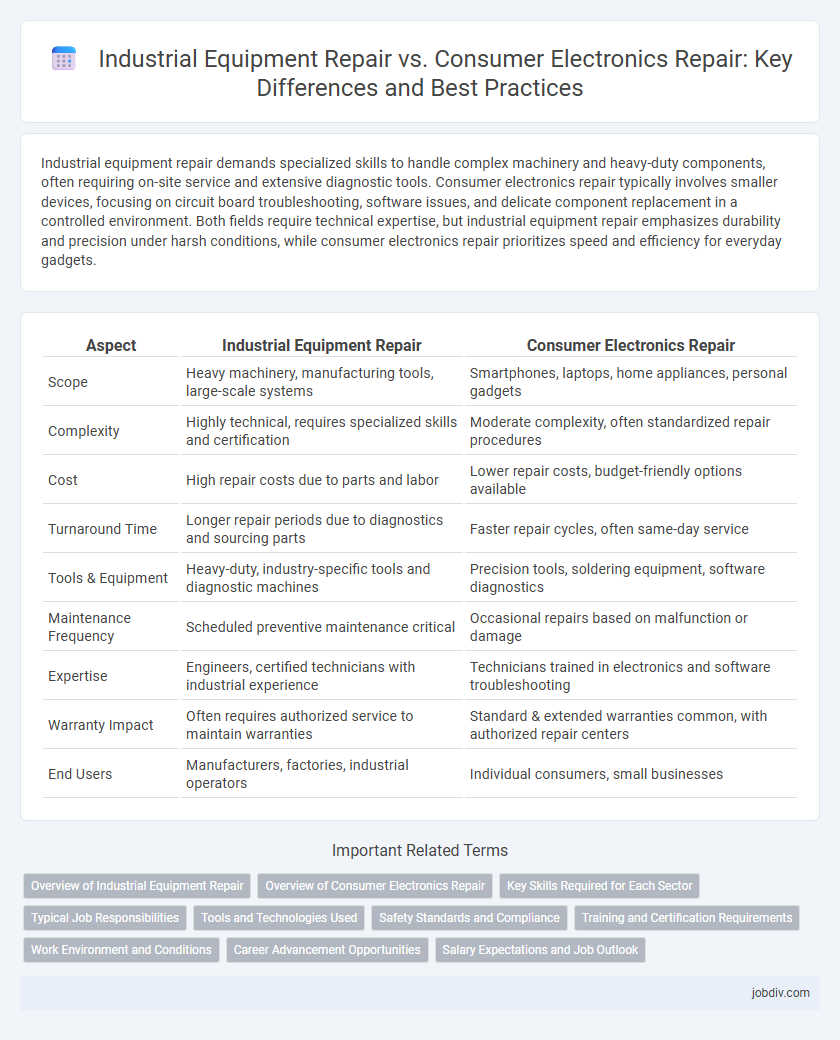

Industrial equipment repair demands specialized skills to handle complex machinery and heavy-duty components, often requiring on-site service and extensive diagnostic tools. Consumer electronics repair typically involves smaller devices, focusing on circuit board troubleshooting, software issues, and delicate component replacement in a controlled environment. Both fields require technical expertise, but industrial equipment repair emphasizes durability and precision under harsh conditions, while consumer electronics repair prioritizes speed and efficiency for everyday gadgets.

Table of Comparison

| Aspect | Industrial Equipment Repair | Consumer Electronics Repair |

|---|---|---|

| Scope | Heavy machinery, manufacturing tools, large-scale systems | Smartphones, laptops, home appliances, personal gadgets |

| Complexity | Highly technical, requires specialized skills and certification | Moderate complexity, often standardized repair procedures |

| Cost | High repair costs due to parts and labor | Lower repair costs, budget-friendly options available |

| Turnaround Time | Longer repair periods due to diagnostics and sourcing parts | Faster repair cycles, often same-day service |

| Tools & Equipment | Heavy-duty, industry-specific tools and diagnostic machines | Precision tools, soldering equipment, software diagnostics |

| Maintenance Frequency | Scheduled preventive maintenance critical | Occasional repairs based on malfunction or damage |

| Expertise | Engineers, certified technicians with industrial experience | Technicians trained in electronics and software troubleshooting |

| Warranty Impact | Often requires authorized service to maintain warranties | Standard & extended warranties common, with authorized repair centers |

| End Users | Manufacturers, factories, industrial operators | Individual consumers, small businesses |

Overview of Industrial Equipment Repair

Industrial equipment repair involves the maintenance and restoration of heavy machinery used in manufacturing, construction, and other industrial sectors, emphasizing durability and precision. This repair process requires specialized skills, advanced diagnostic tools, and adherence to strict safety standards to ensure optimal equipment performance and minimize downtime. Unlike consumer electronics repair, industrial equipment repair often deals with large-scale mechanical systems, hydraulics, and complex electrical components that demand expert technical knowledge.

Overview of Consumer Electronics Repair

Consumer electronics repair focuses on restoring devices such as smartphones, laptops, tablets, and TVs, emphasizing precision due to their compact design and sensitive components. Technicians use specialized tools and diagnostic software to identify issues related to hardware malfunctions, software bugs, or connectivity problems. This repair sector demands continuous skill updates to keep pace with rapidly evolving technology and product models.

Key Skills Required for Each Sector

Industrial equipment repair demands expertise in heavy machinery diagnostics, hydraulic and pneumatic system troubleshooting, and familiarity with industrial safety standards. Consumer electronics repair requires precise skills in micro-soldering, circuit board analysis, and software troubleshooting for devices like smartphones, laptops, and tablets. Both sectors emphasize attention to detail, but industrial repair technicians often need mechanical proficiency while consumer electronics specialists focus on delicate electronic components.

Typical Job Responsibilities

Industrial equipment repair typically involves diagnosing and fixing complex machinery such as conveyor systems, heavy-duty motors, and hydraulic presses used in manufacturing or construction. Technicians in this field perform routine maintenance, troubleshoot mechanical and electrical failures, and ensure compliance with industrial safety standards. Consumer electronics repair focuses on repairing devices like smartphones, laptops, and home appliances by replacing components, updating software, and addressing issues related to circuit boards and connectivity.

Tools and Technologies Used

Industrial equipment repair relies on heavy-duty diagnostic tools such as ultrasonic testers, thermal imaging cameras, and hydraulic pressure gauges designed for large-scale machinery assessment. Consumer electronics repair commonly utilizes precision screwdrivers, soldering stations, multimeters, and anti-static wristbands tailored for delicate circuit boards and microelectronics. Advanced software diagnostic programs and specialized repair kits are integral to both fields, but the scale and complexity of tools differ significantly between heavy industrial machinery and consumer gadgets.

Safety Standards and Compliance

Industrial equipment repair requires strict adherence to rigorous safety standards such as OSHA regulations and ISO 45001 compliance to protect workers from heavy machinery hazards and electrical risks. Consumer electronics repair involves safer environments with a focus on ESD (electrostatic discharge) precautions and compliance with WEEE (Waste Electrical and Electronic Equipment) directives for proper disposal. Both sectors prioritize safety, but industrial repair demands more comprehensive risk assessments and specialized protective equipment to meet regulatory requirements.

Training and Certification Requirements

Industrial equipment repair demands extensive training in mechanical systems, hydraulics, and safety protocols, often requiring certifications such as Certified Maintenance & Reliability Professional (CMRP) or OSHA safety certification to ensure compliance with industry standards. Consumer electronics repair typically involves specialized knowledge of circuitry, software diagnostics, and device-specific tools, with certifications like CompTIA A+ or manufacturer-specific credentials enhancing technician credibility and repair quality. Both fields emphasize continuous education to keep pace with technological advancements and evolving repair techniques.

Work Environment and Conditions

Industrial equipment repair typically occurs in large-scale, often harsh environments such as factories or construction sites, requiring specialized safety gear and adherence to strict occupational standards. Consumer electronics repair is generally conducted in controlled indoor settings like repair shops or home offices, emphasizing precision tools and delicate handling. The physical demands and exposure to hazardous conditions vary significantly, with industrial repair involving heavier machinery and more complex diagnostics compared to the more compact and intricate nature of consumer electronics.

Career Advancement Opportunities

Industrial equipment repair offers extensive career advancement opportunities due to the complexity and scale of machinery involved, often requiring specialized certifications and technical expertise. Consumer electronics repair typically provides faster entry-level positions with skill development but may have limited growth potential compared to industrial sectors. Professionals in industrial repair can progress to roles like maintenance managers or technical trainers, while consumer electronics technicians often advance within retail environments or specialized service centers.

Salary Expectations and Job Outlook

Industrial equipment repair technicians typically earn higher salaries, with average annual wages ranging from $50,000 to $70,000, compared to consumer electronics repair specialists who make around $30,000 to $45,000. The job outlook for industrial equipment repair is strong due to ongoing manufacturing and infrastructure maintenance demands, projecting a growth rate of 7% over the next decade, while consumer electronics repair faces slower growth influenced by rapidly changing technology and product lifecycles. Specialized skills in heavy machinery diagnostics and maintenance further enhance earning potential and employment stability in the industrial sector.

Industrial Equipment Repair vs Consumer Electronics Repair Infographic

jobdiv.com

jobdiv.com