A machinist crafts and shapes metal parts using precision machines and tools, ensuring components meet exact specifications for various applications. A tool repair technician specializes in diagnosing and fixing damaged or worn tools, maintaining the functionality and safety of cutting instruments and machinery parts. Both roles require technical expertise but differ in their primary focus: creating new parts versus restoring existing tools.

Table of Comparison

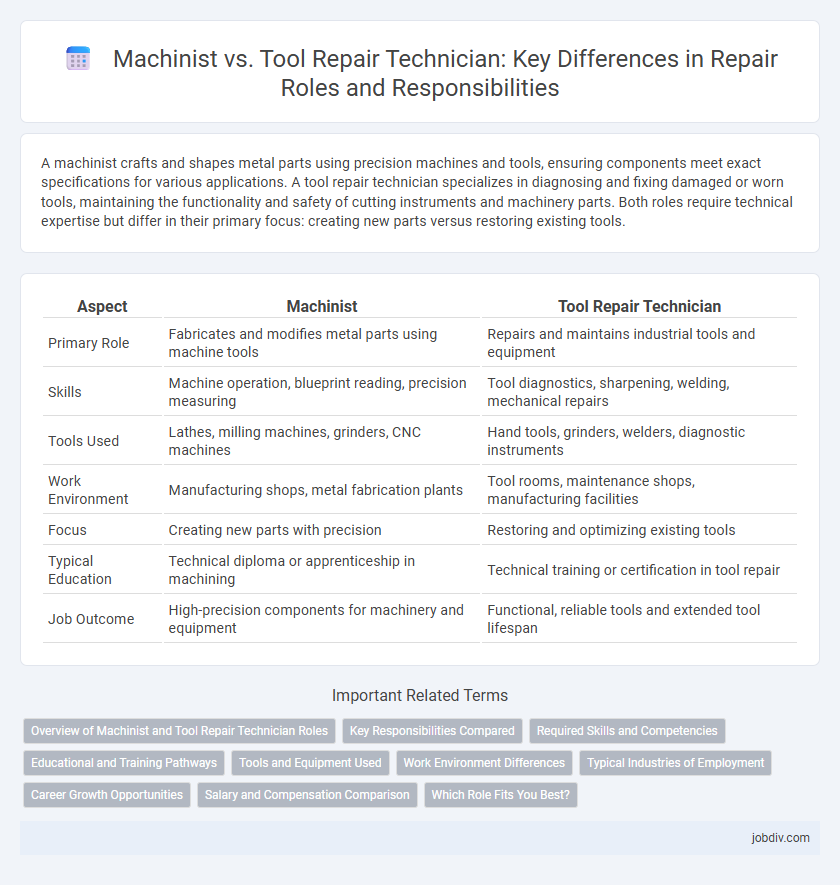

| Aspect | Machinist | Tool Repair Technician |

|---|---|---|

| Primary Role | Fabricates and modifies metal parts using machine tools | Repairs and maintains industrial tools and equipment |

| Skills | Machine operation, blueprint reading, precision measuring | Tool diagnostics, sharpening, welding, mechanical repairs |

| Tools Used | Lathes, milling machines, grinders, CNC machines | Hand tools, grinders, welders, diagnostic instruments |

| Work Environment | Manufacturing shops, metal fabrication plants | Tool rooms, maintenance shops, manufacturing facilities |

| Focus | Creating new parts with precision | Restoring and optimizing existing tools |

| Typical Education | Technical diploma or apprenticeship in machining | Technical training or certification in tool repair |

| Job Outcome | High-precision components for machinery and equipment | Functional, reliable tools and extended tool lifespan |

Overview of Machinist and Tool Repair Technician Roles

Machinists specialize in operating precision machine tools to create, modify, or repair metal parts according to detailed specifications, playing a critical role in manufacturing and production industries. Tool repair technicians focus on maintaining and refurbishing cutting tools, molds, dies, and precision instruments to ensure optimal performance and longevity in manufacturing processes. Both roles require advanced technical skills, knowledge of mechanical systems, and proficiency with measurement instruments, but machinists primarily handle part fabrication while tool repair technicians emphasize tool maintenance and restoration.

Key Responsibilities Compared

Machinists primarily focus on operating machine tools to create or modify precision metal parts according to specifications, ensuring accurate measurements and high-quality finishes. Tool Repair Technicians specialize in maintaining, sharpening, and repairing cutting tools, dies, and molds to ensure optimal performance and longevity. Both roles require mechanical aptitude and attention to detail, but machinists emphasize production and fabrication, while tool repair technicians concentrate on tool maintenance and restoration.

Required Skills and Competencies

Machinists require advanced skills in precision measurement, blueprint interpretation, and computer numerical control (CNC) programming to fabricate and modify metal parts with accuracy. Tool Repair Technicians must have expertise in diagnosing tool malfunctions, performing detailed repairs, and maintaining a broad range of industrial tools and machinery components. Both roles demand strong mechanical aptitude, problem-solving abilities, and proficiency with specialized repair equipment to ensure operational efficiency.

Educational and Training Pathways

Machinists typically undergo vocational training or apprenticeships that emphasize precision machining, blueprint reading, and use of manual and CNC machines, often earning certifications like the National Institute for Metalworking Skills (NIMS). Tool Repair Technicians generally complete specialized technical programs or on-the-job training focusing on the maintenance, calibration, and troubleshooting of cutting tools and machine components, with credentials available through industry organizations such as the Precision Metalforming Association (PMA). Both career paths require strong mechanical aptitude and continuous skill development to keep pace with advancements in manufacturing technology.

Tools and Equipment Used

Machinists primarily utilize precision instruments such as lathes, milling machines, and CNC equipment to fabricate and modify metal parts with high accuracy. Tool Repair Technicians specialize in maintaining and refurbishing hand tools, power tools, and specialized machinery components using grinders, welding equipment, and calibration devices. Both roles require expertise in interpreting technical drawings and employing measurement tools like micrometers and calipers to ensure equipment functionality and longevity.

Work Environment Differences

Machinists typically work in manufacturing plants or machine shops, operating and maintaining heavy machinery in environments that can be noisy and require strict safety protocols. Tool Repair Technicians are often found in specialized repair facilities or equipment maintenance departments, working in cleaner, more controlled settings with a focus on precision tool maintenance and calibration. The work environment for machinists is generally more industrial and physically demanding, while tool repair technicians experience a more technical and detail-oriented atmosphere.

Typical Industries of Employment

Machinists commonly find employment in manufacturing, aerospace, automotive, and metal fabrication industries where precision machining of parts is essential. Tool Repair Technicians are often employed in industrial tool and die shops, manufacturing plants, and maintenance departments across sectors like automotive, aerospace, and electronics. Both roles are critical in environments requiring precise equipment maintenance and part fabrication to ensure operational efficiency.

Career Growth Opportunities

Machinists often have broader career growth opportunities due to their extensive skills in operating and programming various machine tools, which can lead to advanced positions like CNC programmer or production manager. Tool Repair Technicians specialize in maintaining and fixing precision tools and equipment, with growth paths typically focusing on technical expertise or supervisory roles within maintenance departments. Both careers offer paths to senior technician roles, but machinists generally experience faster career advancement given their versatility in manufacturing processes.

Salary and Compensation Comparison

Machinists typically earn a median annual salary of around $45,000 to $60,000, reflecting their specialized skills in operating and maintaining precision machinery. Tool repair technicians, focused on restoring and maintaining tools and equipment, generally earn slightly less, with salaries ranging from $40,000 to $55,000 depending on experience and industry. Both roles may receive additional compensation through overtime, bonuses, and benefits, but machinists often command higher pay due to the technical expertise required for programming and operating CNC machines.

Which Role Fits You Best?

Machinists specialize in operating precision machines to create or modify metal parts, requiring strong skills in blueprint reading and metalworking techniques. Tool Repair Technicians focus on maintaining, troubleshooting, and repairing tools and equipment, demanding expertise in mechanical diagnostics and hand tool restoration. Choosing between these roles depends on whether you prefer hands-on machining processes or detailed tool maintenance and repair tasks.

Machinist vs Tool Repair Technician Infographic

jobdiv.com

jobdiv.com