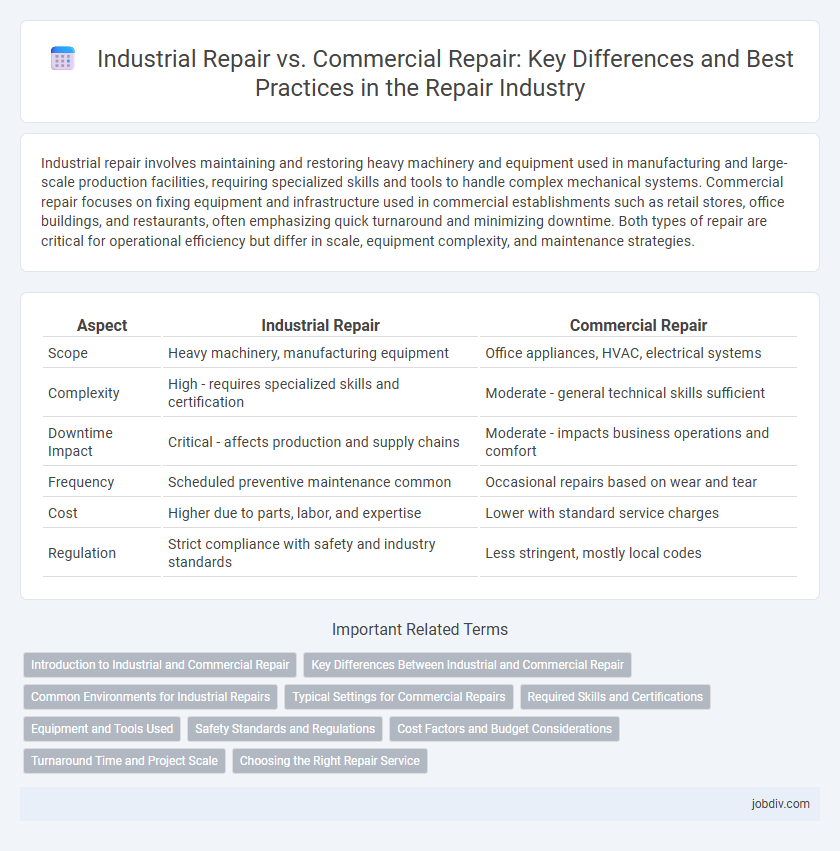

Industrial repair involves maintaining and restoring heavy machinery and equipment used in manufacturing and large-scale production facilities, requiring specialized skills and tools to handle complex mechanical systems. Commercial repair focuses on fixing equipment and infrastructure used in commercial establishments such as retail stores, office buildings, and restaurants, often emphasizing quick turnaround and minimizing downtime. Both types of repair are critical for operational efficiency but differ in scale, equipment complexity, and maintenance strategies.

Table of Comparison

| Aspect | Industrial Repair | Commercial Repair |

|---|---|---|

| Scope | Heavy machinery, manufacturing equipment | Office appliances, HVAC, electrical systems |

| Complexity | High - requires specialized skills and certification | Moderate - general technical skills sufficient |

| Downtime Impact | Critical - affects production and supply chains | Moderate - impacts business operations and comfort |

| Frequency | Scheduled preventive maintenance common | Occasional repairs based on wear and tear |

| Cost | Higher due to parts, labor, and expertise | Lower with standard service charges |

| Regulation | Strict compliance with safety and industry standards | Less stringent, mostly local codes |

Introduction to Industrial and Commercial Repair

Industrial repair focuses on maintaining and restoring heavy machinery and equipment used in manufacturing plants, factories, and production facilities, ensuring minimal downtime and maximizing operational efficiency. Commercial repair involves servicing systems and appliances in businesses such as retail stores, office buildings, and hospitality venues, prioritizing customer accessibility and safety compliance. Both sectors require specialized knowledge but differ in scale, complexity, and regulatory standards.

Key Differences Between Industrial and Commercial Repair

Industrial repair involves maintenance and troubleshooting of heavy machinery and large-scale equipment used in manufacturing and production facilities, often requiring specialized skills and equipment. Commercial repair focuses on fixing systems and infrastructure in retail, office, and service environments, emphasizing quick turnaround and minimal disruption to business operations. Key differences include the scale and complexity of machinery, the technical expertise required, and the impact of downtime on operational productivity.

Common Environments for Industrial Repairs

Industrial repairs typically occur in manufacturing plants, power generation facilities, and heavy machinery workshops where equipment endures intense usage and environmental stress. These environments demand specialized tools and skilled technicians to handle complex machinery such as turbines, conveyor systems, and robotic arms. Regular maintenance and rapid response to breakdowns in these settings are critical to minimize downtime and maintain production efficiency.

Typical Settings for Commercial Repairs

Commercial repairs typically occur in office buildings, retail stores, educational institutions, and healthcare facilities, where maintaining operational efficiency and appearance is crucial. These repairs often involve HVAC systems, plumbing, electrical work, and structural maintenance tailored to high-traffic environments. The emphasis is on minimizing downtime and ensuring compliance with safety codes and industry regulations.

Required Skills and Certifications

Industrial repair demands specialized skills in handling heavy machinery, electrical systems, and automation technology, often requiring certifications such as OSHA, NCCER, and specialized equipment licensing to ensure safety and compliance. Commercial repair focuses on HVAC, plumbing, and electrical systems within office buildings and retail spaces, where certifications like EPA Section 608, Certified Commercial HVAC Technician, and local trade licenses are essential. Both sectors prioritize technical expertise and adherence to regulatory standards, but industrial repair typically involves more complex mechanical and electrical challenges.

Equipment and Tools Used

Industrial repair utilizes heavy-duty equipment such as hydraulic lifts, diagnostic scanners, and CNC machines designed for large-scale machinery maintenance, ensuring precision and durability in complex systems. Commercial repair often relies on portable tools like electric drills, multimeters, and handheld diagnostic devices tailored for smaller mechanical and electrical components in retail or office settings. The variance in equipment highlights the scale and complexity differences between industrial and commercial repair environments.

Safety Standards and Regulations

Industrial repair prioritizes adherence to stringent safety standards such as OSHA regulations and NFPA codes due to the high-risk environments and complex machinery involved. Commercial repair also follows safety protocols but often deals with less hazardous conditions and follows guidelines like the International Building Code (IBC) and local municipal regulations. Both sectors require certified technicians and regular compliance audits to ensure worker safety and operational integrity.

Cost Factors and Budget Considerations

Industrial repair typically involves higher cost factors due to the complexity of machinery, need for specialized technicians, and use of advanced materials, often requiring a larger budget allocation compared to commercial repair. Commercial repair generally incurs lower expenses as it deals with less complex systems and more standardized equipment, making budgeting more predictable and manageable. Considering the scale and technical demands in industrial settings is crucial for accurate cost estimation and efficient budget planning.

Turnaround Time and Project Scale

Industrial repair projects typically involve large-scale equipment or facilities, resulting in longer turnaround times due to complex machinery and extensive safety protocols. Commercial repair generally addresses smaller-scale issues such as HVAC systems or electrical faults, enabling faster completion within shorter project scopes. Efficient project management and resource allocation are crucial to minimizing downtime in both industrial and commercial repair settings.

Choosing the Right Repair Service

Industrial repair services specialize in maintaining and fixing heavy machinery and equipment used in manufacturing and production facilities, ensuring minimal downtime and compliance with safety standards. Commercial repair focuses on office buildings, retail shops, and other business environments, addressing HVAC, electrical, and structural issues to maintain operational efficiency. Choosing the right repair service depends on the specific equipment, environment, and scope of work, with industrial repairs requiring specialized technical knowledge and certifications.

Industrial Repair vs Commercial Repair Infographic

jobdiv.com

jobdiv.com