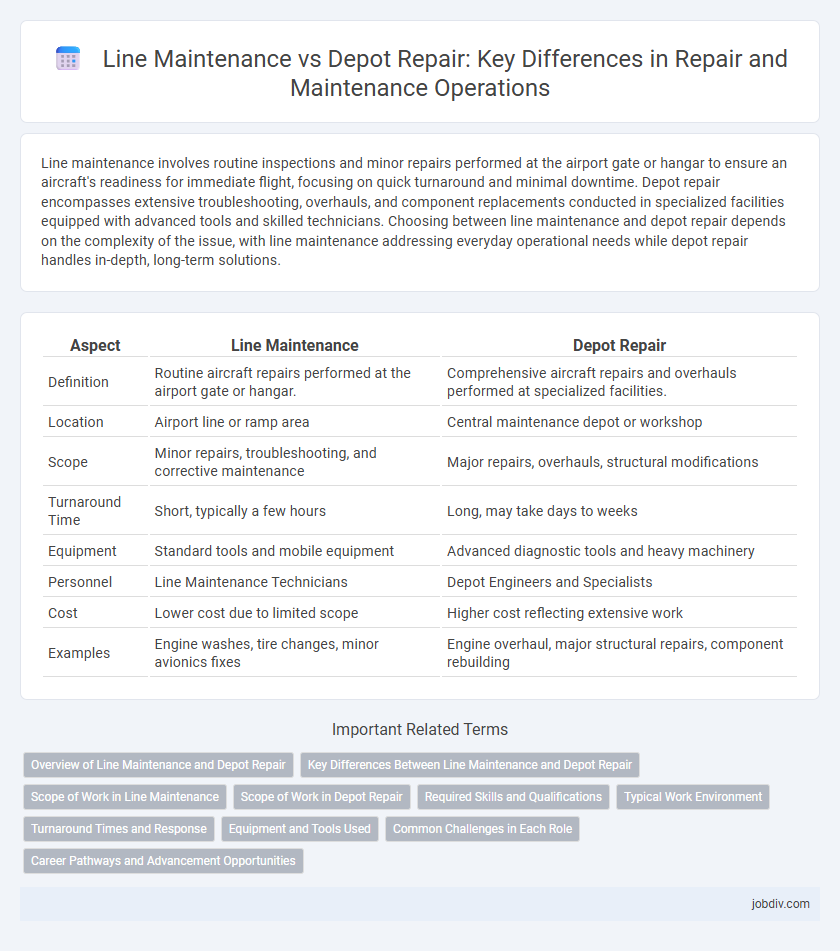

Line maintenance involves routine inspections and minor repairs performed at the airport gate or hangar to ensure an aircraft's readiness for immediate flight, focusing on quick turnaround and minimal downtime. Depot repair encompasses extensive troubleshooting, overhauls, and component replacements conducted in specialized facilities equipped with advanced tools and skilled technicians. Choosing between line maintenance and depot repair depends on the complexity of the issue, with line maintenance addressing everyday operational needs while depot repair handles in-depth, long-term solutions.

Table of Comparison

| Aspect | Line Maintenance | Depot Repair |

|---|---|---|

| Definition | Routine aircraft repairs performed at the airport gate or hangar. | Comprehensive aircraft repairs and overhauls performed at specialized facilities. |

| Location | Airport line or ramp area | Central maintenance depot or workshop |

| Scope | Minor repairs, troubleshooting, and corrective maintenance | Major repairs, overhauls, structural modifications |

| Turnaround Time | Short, typically a few hours | Long, may take days to weeks |

| Equipment | Standard tools and mobile equipment | Advanced diagnostic tools and heavy machinery |

| Personnel | Line Maintenance Technicians | Depot Engineers and Specialists |

| Cost | Lower cost due to limited scope | Higher cost reflecting extensive work |

| Examples | Engine washes, tire changes, minor avionics fixes | Engine overhaul, major structural repairs, component rebuilding |

Overview of Line Maintenance and Depot Repair

Line maintenance involves routine inspections and minor repairs performed on aircraft at the airport gate or on the ramp to ensure immediate airworthiness and minimize downtime. Depot repair encompasses comprehensive, in-depth maintenance and overhaul activities conducted at specialized facilities equipped with advanced tools and skilled technicians for major component repairs and system refurbishments. Together, line maintenance and depot repair form a synergistic approach to aircraft upkeep, balancing operational efficiency with extensive technical support.

Key Differences Between Line Maintenance and Depot Repair

Line maintenance involves routine inspections, troubleshooting, and minor repairs performed on an aircraft while it is in service, typically at an airport gate or hangar. Depot repair refers to extensive, in-depth overhauls, structural repairs, and major component replacements conducted at specialized facilities equipped with advanced tooling and testing equipment. Key differences include the scope of work, turnaround time, and location, with line maintenance focused on quick fixes to keep aircraft operational and depot repair targeting complex, long-term restoration and refurbishment.

Scope of Work in Line Maintenance

Line maintenance involves routine inspections, minor repairs, and immediate troubleshooting performed on aircraft between flights to ensure operational safety and compliance. Tasks typically include checking fluid levels, replacing batteries or tires, addressing minor defects, and conducting system functional tests. This scope of work is designed to minimize aircraft downtime and support continuous flight readiness without requiring extensive disassembly or long-term repairs.

Scope of Work in Depot Repair

Depot repair encompasses comprehensive maintenance tasks including major component overhauls, structural repairs, and system upgrades that exceed the capabilities of line maintenance. It involves detailed inspections, complex troubleshooting, and the replacement or refurbishment of critical parts within specialized facilities. This extensive scope ensures aircraft systems and components are restored to optimal condition, supporting long-term reliability and safety.

Required Skills and Qualifications

Line Maintenance technicians must possess strong troubleshooting skills, basic mechanical knowledge, and certifications such as A&P (Airframe and Powerplant) or equivalent, enabling them to perform quick inspections and minor repairs efficiently. Depot Repair specialists require advanced technical expertise, often including degrees in aerospace engineering or specialized training, as well as experience with complex systems diagnostics, component overhauls, and adherence to manufacturer repair manuals. Both roles demand strict compliance with aviation safety regulations and continuous skill updates to maintain aircraft airworthiness.

Typical Work Environment

Line maintenance typically occurs at airport ramps or gates with fast-paced conditions requiring immediate troubleshooting and minor repairs to keep aircraft operational for daily flights. Depot repair takes place in specialized hangars or workshops equipped with advanced diagnostic tools and facilities designed for extensive inspections, component overhauls, and structural repairs. The line maintenance environment prioritizes quick turnaround times, while depot repair emphasizes thorough, in-depth servicing in a controlled setting.

Turnaround Times and Response

Line maintenance offers rapid turnaround times by addressing minor repairs and routine checks directly on the aircraft, minimizing downtime and ensuring quick response to operational needs. Depot repair involves comprehensive overhauls and complex repairs performed in specialized facilities, generally requiring longer turnaround times due to the depth of inspection and part replacements. Efficient coordination between line maintenance and depot repair teams optimizes overall aircraft availability and service reliability.

Equipment and Tools Used

Line maintenance primarily utilizes portable, lightweight tools and diagnostic equipment designed for quick inspections, minor repairs, and routine checks directly on the aircraft at the gate or on the tarmac. Depot repair involves extensive use of specialized machinery, heavy-duty tools, and advanced testing devices within a controlled workshop environment, enabling comprehensive overhauls and component replacements. The distinction in equipment reflects the differing scopes, with line maintenance focusing on immediate serviceability and depot repair emphasizing in-depth refurbishment.

Common Challenges in Each Role

Line maintenance faces common challenges such as limited time constraints for quick fixes, unpredictable troubleshooting scenarios, and the need to ensure aircraft safety between flights. Depot repair often involves complex diagnostic processes, extensive component overhauls, and managing long turnaround times to maintain aircraft readiness. Both roles require skilled technicians and effective coordination to minimize aircraft downtime and ensure operational efficiency.

Career Pathways and Advancement Opportunities

Line maintenance offers technicians hands-on experience with routine inspections and minor repairs, serving as an entry point into the aviation maintenance career ladder. Depot repair involves extensive overhauls and complex system troubleshooting, providing advanced skill development crucial for senior technical roles. Progression from line maintenance to depot repair often leads to specialized certifications and supervisory positions, enhancing career advancement opportunities in the aerospace industry.

Line Maintenance vs Depot Repair Infographic

jobdiv.com

jobdiv.com