Preventive maintenance for pets involves regular check-ups, vaccinations, and consistent grooming to identify potential health issues before they become serious problems, ensuring long-term well-being. Reactive repair addresses pet health only after symptoms or injuries appear, which can lead to higher treatment costs and prolonged recovery. Prioritizing preventive care reduces the risk of emergency visits and supports a healthier, happier pet throughout its life.

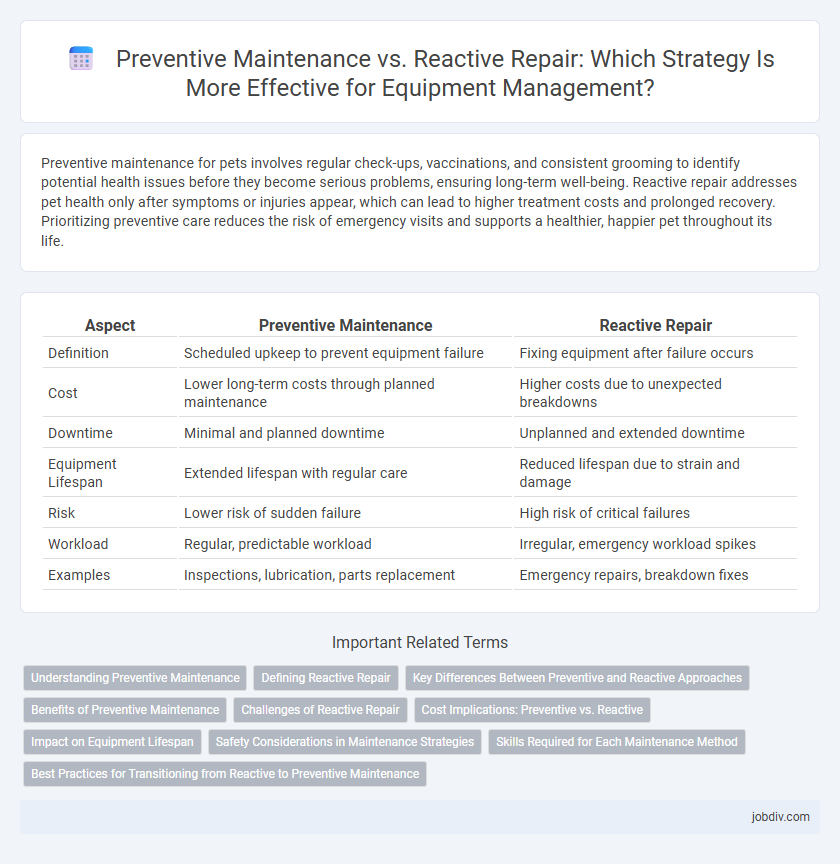

Table of Comparison

| Aspect | Preventive Maintenance | Reactive Repair |

|---|---|---|

| Definition | Scheduled upkeep to prevent equipment failure | Fixing equipment after failure occurs |

| Cost | Lower long-term costs through planned maintenance | Higher costs due to unexpected breakdowns |

| Downtime | Minimal and planned downtime | Unplanned and extended downtime |

| Equipment Lifespan | Extended lifespan with regular care | Reduced lifespan due to strain and damage |

| Risk | Lower risk of sudden failure | High risk of critical failures |

| Workload | Regular, predictable workload | Irregular, emergency workload spikes |

| Examples | Inspections, lubrication, parts replacement | Emergency repairs, breakdown fixes |

Understanding Preventive Maintenance

Preventive maintenance involves regularly scheduled inspections and servicing to identify and fix potential issues before they cause equipment failure. This proactive approach reduces downtime, extends asset lifespan, and lowers overall maintenance costs compared to reactive repair, which occurs only after a breakdown. Effective preventive maintenance programs rely on data-driven scheduling, condition monitoring, and timely interventions to ensure optimal equipment performance.

Defining Reactive Repair

Reactive repair refers to addressing equipment failures or malfunctions only after they occur, often leading to unexpected downtime and higher costs. This approach contrasts with preventive maintenance, which involves scheduled inspections and servicing to prevent breakdowns. Reactive repair is typically more urgent and can result in extended operational interruptions and increased repair expenses.

Key Differences Between Preventive and Reactive Approaches

Preventive maintenance involves regular, scheduled inspections and servicing to detect and address potential issues before failure occurs, minimizing downtime and extending equipment lifespan. Reactive repair occurs only after a breakdown, focusing on fixing the problem as it arises, often resulting in higher costs and unexpected disruptions. Key differences include cost predictability, equipment reliability, and maintenance scheduling, with preventive strategies offering proactive control and reactive approaches responding to urgent failures.

Benefits of Preventive Maintenance

Preventive maintenance reduces equipment downtime by addressing potential issues before they cause failures, enhancing operational efficiency and extending asset lifespan. It lowers repair costs through early detection and minimizes unexpected breakdowns, ensuring consistent productivity. Implementing a scheduled maintenance plan boosts safety and compliance, reducing the risk of accidents and regulatory penalties.

Challenges of Reactive Repair

Reactive repair presents significant challenges including unexpected downtime, increased repair costs, and reduced equipment lifespan. The lack of scheduled maintenance often results in costly emergency fixes and disrupts operational efficiency. Moreover, reactive repair limits the ability to predict and prevent failures, causing overall system unreliability.

Cost Implications: Preventive vs. Reactive

Preventive maintenance significantly reduces long-term costs by addressing potential equipment issues before they escalate into major failures, minimizing downtime and expensive emergency repairs. Reactive repair often incurs higher immediate expenses due to urgent part replacements, labor costs, and unplanned operational interruptions. Investing in preventive maintenance optimizes asset lifespan and lowers overall maintenance budgets compared to the unpredictable and costly nature of reactive repair.

Impact on Equipment Lifespan

Preventive maintenance extends equipment lifespan by systematically addressing potential issues before they escalate into serious problems, reducing wear and tear. Reactive repair, triggered only after failures occur, often leads to increased downtime and accelerated deterioration, which shortens overall equipment longevity. Consistently implementing preventive maintenance strategies ensures optimal performance and maximizes the useful life of machinery.

Safety Considerations in Maintenance Strategies

Preventive maintenance prioritizes safety by systematically identifying and addressing potential equipment failures before they occur, reducing the risk of accidents and ensuring compliance with safety regulations. Reactive repair can lead to unexpected breakdowns that compromise worker safety and increase the likelihood of hazardous incidents due to unplanned downtime. Implementing a preventive maintenance strategy enhances workplace safety by maintaining optimal equipment conditions and minimizing exposure to dangerous malfunctions.

Skills Required for Each Maintenance Method

Preventive maintenance requires skills such as systematic inspection, diagnostic analysis, and routine servicing to identify and address potential issues before failures occur. Reactive repair demands proficiency in troubleshooting, rapid problem-solving, and hands-on technical expertise to fix unexpected breakdowns quickly. Both methods require a solid understanding of mechanical and electrical systems, but preventive maintenance emphasizes predictive skills while reactive repair prioritizes immediate corrective action.

Best Practices for Transitioning from Reactive to Preventive Maintenance

Implementing a preventive maintenance strategy requires thorough asset management and consistent monitoring to identify potential failures before they occur. Utilizing predictive analytics tools and scheduling routine inspections significantly reduces unexpected downtime and repair costs associated with reactive maintenance. Training personnel on maintenance best practices ensures smooth adoption and long-term operational efficiency.

Preventive Maintenance vs Reactive Repair Infographic

jobdiv.com

jobdiv.com