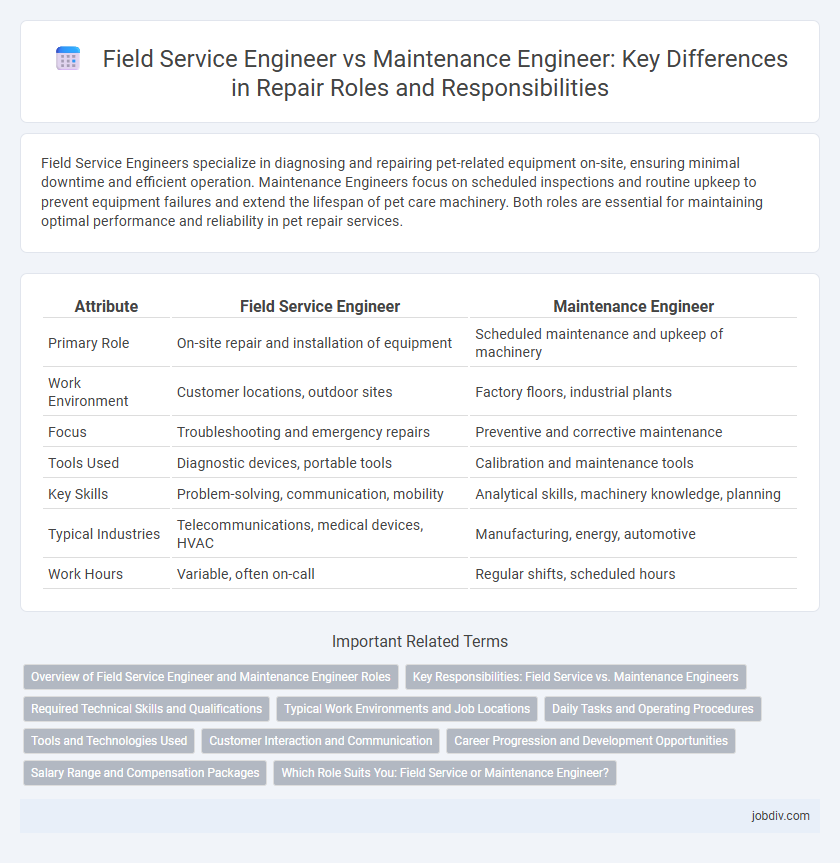

Field Service Engineers specialize in diagnosing and repairing pet-related equipment on-site, ensuring minimal downtime and efficient operation. Maintenance Engineers focus on scheduled inspections and routine upkeep to prevent equipment failures and extend the lifespan of pet care machinery. Both roles are essential for maintaining optimal performance and reliability in pet repair services.

Table of Comparison

| Attribute | Field Service Engineer | Maintenance Engineer |

|---|---|---|

| Primary Role | On-site repair and installation of equipment | Scheduled maintenance and upkeep of machinery |

| Work Environment | Customer locations, outdoor sites | Factory floors, industrial plants |

| Focus | Troubleshooting and emergency repairs | Preventive and corrective maintenance |

| Tools Used | Diagnostic devices, portable tools | Calibration and maintenance tools |

| Key Skills | Problem-solving, communication, mobility | Analytical skills, machinery knowledge, planning |

| Typical Industries | Telecommunications, medical devices, HVAC | Manufacturing, energy, automotive |

| Work Hours | Variable, often on-call | Regular shifts, scheduled hours |

Overview of Field Service Engineer and Maintenance Engineer Roles

Field Service Engineers specialize in on-site troubleshooting, installation, and repair of equipment, ensuring optimal functionality and minimizing downtime. Maintenance Engineers focus on routine inspections, preventive maintenance, and system upgrades to extend the lifespan of machinery and improve operational efficiency. Both roles require technical expertise but differ in scope, with Field Service Engineers addressing immediate technical issues and Maintenance Engineers managing ongoing system reliability.

Key Responsibilities: Field Service vs. Maintenance Engineers

Field Service Engineers primarily focus on on-site troubleshooting, installation, and repair of equipment, ensuring immediate resolution of technical issues to minimize downtime. Maintenance Engineers concentrate on preventive maintenance, routine inspections, and scheduling repairs to enhance equipment reliability and extend operational lifespan. Both roles require strong technical expertise but differ in their approach to equipment management and downtime prevention.

Required Technical Skills and Qualifications

Field Service Engineers require advanced diagnostic and troubleshooting skills, proficiency in electronic systems, and the ability to manage on-site repairs under varying conditions, often supported by certifications in robotics, electrical engineering, or mechanical systems. Maintenance Engineers prioritize preventive maintenance expertise, knowledge of system optimization, and familiarity with computerized maintenance management systems (CMMS), usually holding qualifications in industrial maintenance or mechanical engineering. Both roles demand strong problem-solving capabilities and technical training, but Field Service Engineers focus on reactive repair skills while Maintenance Engineers emphasize proactive system upkeep.

Typical Work Environments and Job Locations

Field Service Engineers predominantly operate at client sites, such as manufacturing plants, hospitals, or construction locations, providing on-site technical support and equipment repairs in diverse and dynamic environments. Maintenance Engineers are typically stationed within the facility they service, like factories or industrial complexes, focusing on routine inspections, preventive maintenance, and system optimization to ensure continuous operation. Both roles require adaptability to varying conditions, but Field Service Engineers often encounter a broader range of environments due to travel and client interaction demands.

Daily Tasks and Operating Procedures

Field Service Engineers typically perform on-site troubleshooting, diagnostics, and repairs of equipment at client locations, following strict safety protocols and manufacturer guidelines to ensure operational efficiency. Maintenance Engineers focus on scheduled preventive maintenance, equipment inspections, and system upgrades within facilities, adhering to maintenance schedules and compliance standards to minimize downtime. Both roles require detailed documentation of repairs and maintenance activities to support asset management and regulatory compliance.

Tools and Technologies Used

Field Service Engineers utilize portable diagnostic tools, advanced software applications, and remote monitoring technologies to troubleshoot and repair equipment on-site efficiently. Maintenance Engineers typically employ predictive maintenance tools, computerized maintenance management systems (CMMS), and calibration instruments to ensure ongoing equipment reliability and performance. Both roles integrate IoT sensors and data analytics platforms to enhance workflow and minimize downtime through real-time insights.

Customer Interaction and Communication

Field Service Engineers often engage directly with customers on-site, addressing urgent repairs and providing real-time troubleshooting, which requires strong interpersonal and communication skills tailored to diverse client needs. Maintenance Engineers typically focus on planned upkeep within a controlled environment, where communication is more technical and often conducted internally with operations teams. Effective customer interaction differentiates Field Service Engineers by emphasizing personalized service and clear explanations to non-technical users.

Career Progression and Development Opportunities

Field Service Engineers advance through roles involving complex troubleshooting, client interaction, and project management, enhancing skills in diagnostics and customer relations critical for career progression. Maintenance Engineers progress by gaining expertise in preventive maintenance, reliability engineering, and asset management, opening pathways to supervisory and engineering management positions. Both career paths offer specialized certifications and training programs that facilitate continuous professional development and leadership opportunities in industrial and technical sectors.

Salary Range and Compensation Packages

Field Service Engineers typically earn between $55,000 and $85,000 annually, with compensation packages often including travel allowances and performance bonuses due to their on-site repair responsibilities. Maintenance Engineers usually have a salary range of $50,000 to $80,000, benefiting from structured benefits like overtime pay and shift differentials tied to plant or facility upkeep. Both roles offer variable incentives, but Field Service Engineers may receive higher overall compensation influenced by technical expertise and frequent client interaction.

Which Role Suits You: Field Service or Maintenance Engineer?

Field Service Engineers specialize in on-site troubleshooting, installation, and repair of equipment, often requiring extensive travel and direct customer interaction, making the role ideal for professionals who enjoy dynamic work environments and problem-solving in diverse settings. Maintenance Engineers focus on preventive and corrective maintenance within a fixed facility, ensuring machinery operates efficiently and downtime is minimized, suitable for individuals who prefer structured schedules and in-depth technical oversight. Choosing between these roles depends on your preference for mobility versus stability, customer engagement, and hands-on technical challenges in either field operations or plant maintenance.

Field Service Engineer vs Maintenance Engineer Infographic

jobdiv.com

jobdiv.com