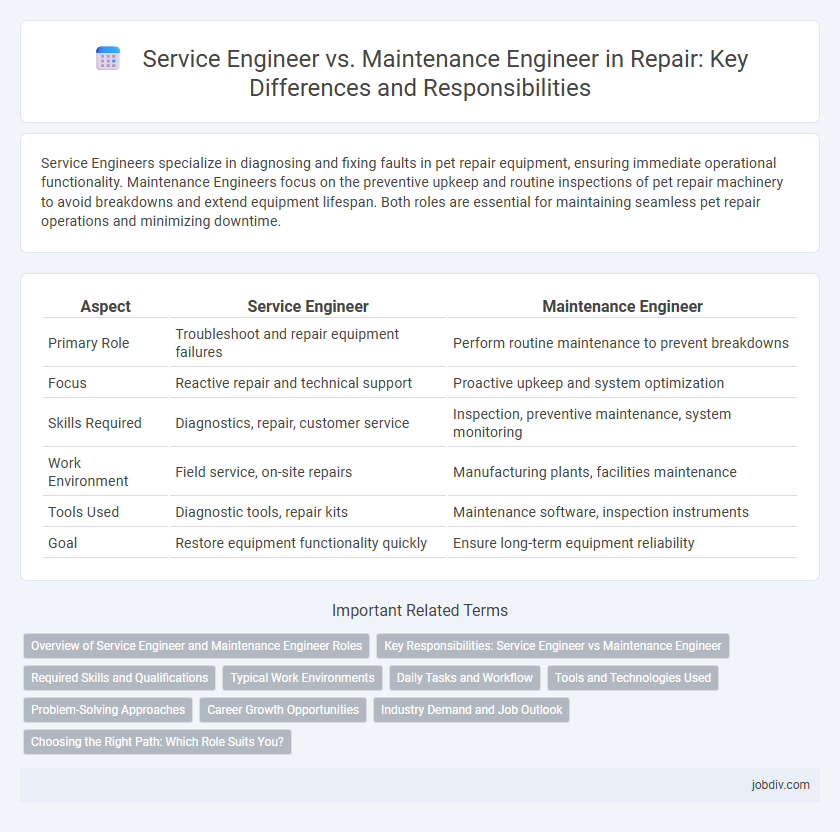

Service Engineers specialize in diagnosing and fixing faults in pet repair equipment, ensuring immediate operational functionality. Maintenance Engineers focus on the preventive upkeep and routine inspections of pet repair machinery to avoid breakdowns and extend equipment lifespan. Both roles are essential for maintaining seamless pet repair operations and minimizing downtime.

Table of Comparison

| Aspect | Service Engineer | Maintenance Engineer |

|---|---|---|

| Primary Role | Troubleshoot and repair equipment failures | Perform routine maintenance to prevent breakdowns |

| Focus | Reactive repair and technical support | Proactive upkeep and system optimization |

| Skills Required | Diagnostics, repair, customer service | Inspection, preventive maintenance, system monitoring |

| Work Environment | Field service, on-site repairs | Manufacturing plants, facilities maintenance |

| Tools Used | Diagnostic tools, repair kits | Maintenance software, inspection instruments |

| Goal | Restore equipment functionality quickly | Ensure long-term equipment reliability |

Overview of Service Engineer and Maintenance Engineer Roles

Service engineers specialize in diagnosing, repairing, and calibrating equipment to ensure optimal performance, often providing on-site technical support and troubleshooting for complex machinery. Maintenance engineers focus on preventive maintenance, routine inspections, and system upgrades to minimize equipment downtime and prolong asset lifespan. Both roles require expertise in mechanical and electrical systems, but service engineers prioritize immediate repair solutions while maintenance engineers emphasize long-term operational reliability.

Key Responsibilities: Service Engineer vs Maintenance Engineer

Service Engineers focus on diagnosing and repairing equipment faults, performing installations, and providing technical support to ensure optimal device functionality. Maintenance Engineers prioritize routine inspections, preventive measures, and equipment upkeep to minimize downtime and extend machinery lifespan. Both roles require specialized technical knowledge but differ in reactive versus proactive approaches to equipment management.

Required Skills and Qualifications

Service engineers require strong diagnostic and troubleshooting skills focused on repairing complex equipment, combined with proficiency in specific technical systems and excellent customer service abilities. Maintenance engineers need expertise in preventive maintenance techniques, equipment reliability, and process optimization, often supported by qualifications in mechanical, electrical, or industrial engineering. Both roles demand relevant certifications such as electrical safety, PLC programming, and often experience with computerized maintenance management systems (CMMS).

Typical Work Environments

Service Engineers typically work in client-focused environments such as manufacturing plants, hospitals, or commercial facilities, where they perform on-site repairs and technical support to ensure equipment functionality. Maintenance Engineers often operate within industrial settings, including factories, refineries, and large-scale production units, focusing on preventive maintenance and system optimization to avoid machinery downtime. Both roles demand adaptability to diverse operational conditions, with Service Engineers frequently traveling to various locations and Maintenance Engineers working predominantly within a fixed plant or facility.

Daily Tasks and Workflow

Service engineers troubleshoot and repair equipment breakdowns, responding promptly to malfunctions to restore functionality and minimize downtime. Maintenance engineers plan and execute routine inspections, preventive maintenance, and system upgrades to enhance equipment reliability and extend lifecycle. Both roles require detailed documentation of work performed and collaboration with production teams to ensure operational efficiency.

Tools and Technologies Used

Service engineers primarily utilize diagnostic tools, advanced software, and calibration instruments to troubleshoot and repair equipment efficiently, ensuring optimal performance. Maintenance engineers rely on predictive maintenance technologies, condition monitoring systems, and preventive repair tools to minimize downtime and extend the lifespan of machinery. Both roles integrate IoT-enabled devices and data analytics platforms to enhance precision and workflow in industrial repair processes.

Problem-Solving Approaches

Service Engineers specialize in diagnosing and fixing immediate equipment malfunctions using real-time troubleshooting techniques and specialized diagnostic tools. Maintenance Engineers emphasize preventive strategies, employing systematic inspections and predictive analytics to identify potential failures before they occur, thereby reducing downtime. Both roles collaborate by integrating reactive repairs with proactive maintenance plans to ensure optimal operational efficiency.

Career Growth Opportunities

Service engineers specialize in troubleshooting and repairing equipment, gaining hands-on experience with diverse technologies, which propels them toward advanced technical roles and specialized certifications. Maintenance engineers focus on optimizing system reliability and implementing preventive strategies, positioning themselves for leadership roles in operations management and process improvement. Both career paths offer robust growth opportunities, with service engineers advancing in field expertise and maintenance engineers rising in strategic oversight and project management.

Industry Demand and Job Outlook

Service Engineers specialize in troubleshooting and repairing complex machinery and equipment, addressing breakdowns to minimize downtime in manufacturing and industrial settings. Maintenance Engineers focus on preventive strategies and optimizing the performance and reliability of systems, which is critical for sustaining long-term operational efficiency. Industry demand favors Maintenance Engineers due to a growing emphasis on predictive maintenance and automation, while Service Engineers remain essential for emergency repairs and specialized technical interventions.

Choosing the Right Path: Which Role Suits You?

Service engineers specialize in troubleshooting and repairing equipment to restore functionality quickly, ideal for those who enjoy dynamic problem-solving and varied daily tasks. Maintenance engineers focus on preventive measures and routine inspections to ensure long-term operational efficiency, suited for individuals who prefer systematic planning and sustainability in machinery performance. Understanding the distinct responsibilities and skill sets of each role helps in making an informed decision aligned with career goals and personal strengths.

Service Engineer vs Maintenance Engineer Infographic

jobdiv.com

jobdiv.com