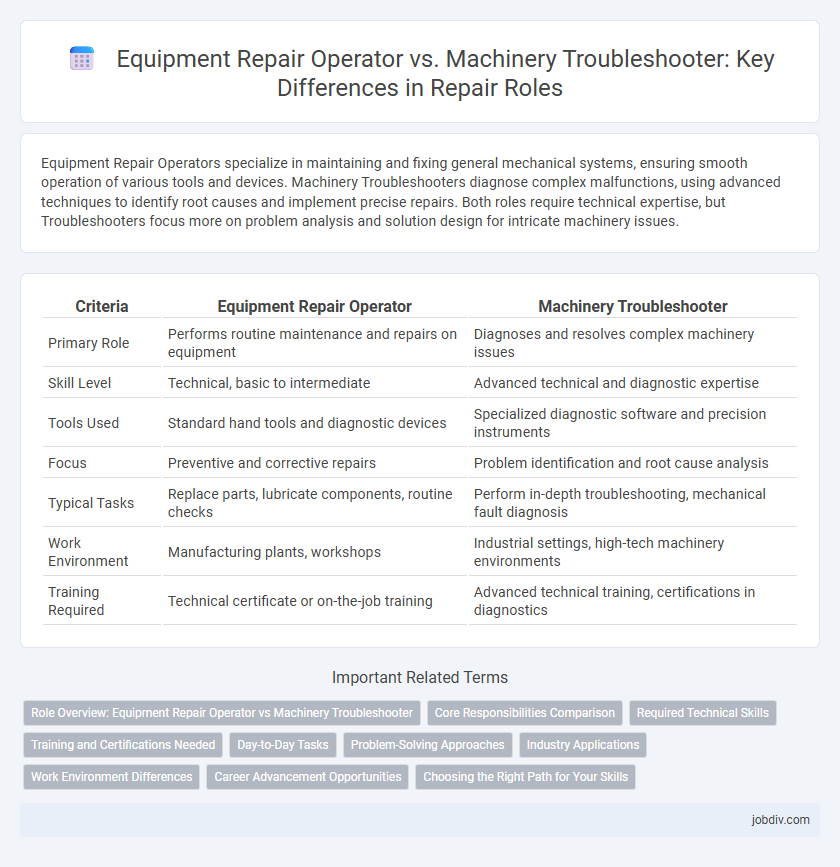

Equipment Repair Operators specialize in maintaining and fixing general mechanical systems, ensuring smooth operation of various tools and devices. Machinery Troubleshooters diagnose complex malfunctions, using advanced techniques to identify root causes and implement precise repairs. Both roles require technical expertise, but Troubleshooters focus more on problem analysis and solution design for intricate machinery issues.

Table of Comparison

| Criteria | Equipment Repair Operator | Machinery Troubleshooter |

|---|---|---|

| Primary Role | Performs routine maintenance and repairs on equipment | Diagnoses and resolves complex machinery issues |

| Skill Level | Technical, basic to intermediate | Advanced technical and diagnostic expertise |

| Tools Used | Standard hand tools and diagnostic devices | Specialized diagnostic software and precision instruments |

| Focus | Preventive and corrective repairs | Problem identification and root cause analysis |

| Typical Tasks | Replace parts, lubricate components, routine checks | Perform in-depth troubleshooting, mechanical fault diagnosis |

| Work Environment | Manufacturing plants, workshops | Industrial settings, high-tech machinery environments |

| Training Required | Technical certificate or on-the-job training | Advanced technical training, certifications in diagnostics |

Role Overview: Equipment Repair Operator vs Machinery Troubleshooter

Equipment Repair Operators primarily focus on performing routine maintenance, diagnosing mechanical issues, and repairing equipment to ensure operational efficiency in industrial settings. Machinery Troubleshooters specialize in identifying complex malfunctions, analyzing system failures, and implementing precise corrective actions to minimize downtime in manufacturing plants. Both roles require technical expertise, but Equipment Repair Operators often handle standard repairs while Machinery Troubleshooters address advanced mechanical problems.

Core Responsibilities Comparison

Equipment Repair Operators specialize in maintaining and repairing operational machinery to ensure consistent performance and safety compliance, focusing on routine inspections, preventive maintenance, and minor repairs. Machinery Troubleshooters diagnose complex mechanical, electrical, and hydraulic issues by analyzing system malfunctions, interpreting technical manuals, and implementing corrective actions to minimize downtime. Both roles require strong technical skills, but Equipment Repair Operators emphasize maintenance tasks while Machinery Troubleshooters prioritize problem-solving and detailed diagnostics for advanced equipment failures.

Required Technical Skills

Equipment Repair Operators require proficiency in diagnosing mechanical failures, interpreting electrical schematics, and performing routine maintenance to ensure optimal equipment functionality. Machinery Troubleshooters specialize in advanced diagnostic tools, understanding complex control systems, and applying problem-solving techniques to identify and resolve intricate machinery issues. Both roles demand expertise in hydraulic, pneumatic, and electronic systems, but Troubleshooters often handle more sophisticated technical challenges.

Training and Certifications Needed

Equipment Repair Operators typically require hands-on vocational training and certifications in mechanical systems, hydraulics, and electrical components to efficiently maintain and repair industrial equipment. Machinery Troubleshooters need advanced certifications in diagnostics, programmable logic controllers (PLCs), and specialized software for fault analysis to identify and resolve complex mechanical and electronic issues. Both roles benefit from OSHA safety certifications and ongoing technical education to stay updated with evolving repair technologies and industry standards.

Day-to-Day Tasks

Equipment Repair Operators perform routine maintenance, inspect machinery for wear and tear, and replace faulty components to ensure optimal operation. Machinery Troubleshooters diagnose complex mechanical and electrical issues using diagnostic tools and schematics, often focusing on problem-solving and corrective repairs. Both roles require technical expertise, but Troubleshooters typically handle more specialized tasks involving intricate system failures.

Problem-Solving Approaches

Equipment Repair Operators primarily utilize diagnostic tools and standard repair protocols to identify and fix mechanical issues, emphasizing routine maintenance and immediate restoration of equipment functionality. Machinery Troubleshooters apply advanced problem-solving techniques, including root cause analysis and predictive maintenance strategies, to address complex systemic malfunctions and prevent future breakdowns. Both roles demand strong technical knowledge, but Troubleshooters often engage in more in-depth analysis to optimize machinery performance over time.

Industry Applications

Equipment Repair Operators maintain and restore industrial machinery, ensuring continuous production in sectors like manufacturing, power generation, and food processing. Machinery Troubleshooters specialize in diagnosing complex mechanical issues, optimizing performance and minimizing downtime in industries such as automotive, aerospace, and heavy equipment repair. Both roles are critical in sustaining operational efficiency and safety across diverse industrial applications.

Work Environment Differences

Equipment Repair Operators typically work in structured industrial settings such as factories or manufacturing plants, where tasks follow scheduled maintenance protocols and safety regulations. Machinery Troubleshooters often operate in dynamic environments, including construction sites or field locations, requiring adaptability to varied equipment types and urgent problem-solving under time constraints. The contrasting work environments influence the scope of responsibilities, with Operators focusing on routine repairs and Troubleshooters addressing complex, unpredictable mechanical failures.

Career Advancement Opportunities

Equipment Repair Operators often advance by gaining certifications in specific equipment systems, enabling promotion to supervisory roles or specialized technician positions within manufacturing plants. Machinery Troubleshooters leverage their problem-solving expertise to transition into roles such as maintenance engineers or field service managers, often commanding higher salaries due to their diagnostic skills. Both career paths benefit from continuous technical training and industry-specific knowledge, enhancing opportunities for leadership and advanced operational roles.

Choosing the Right Path for Your Skills

Equipment Repair Operators excel in routine maintenance and minor repairs, utilizing hands-on technical skills to ensure machinery operates smoothly. Machinery Troubleshooters specialize in diagnosing complex mechanical and electrical issues, requiring advanced problem-solving abilities and in-depth system knowledge. Selecting the right path depends on your proficiency in either consistent operational upkeep or analytical troubleshooting of specialized equipment failures.

Equipment Repair Operator vs Machinery Troubleshooter Infographic

jobdiv.com

jobdiv.com