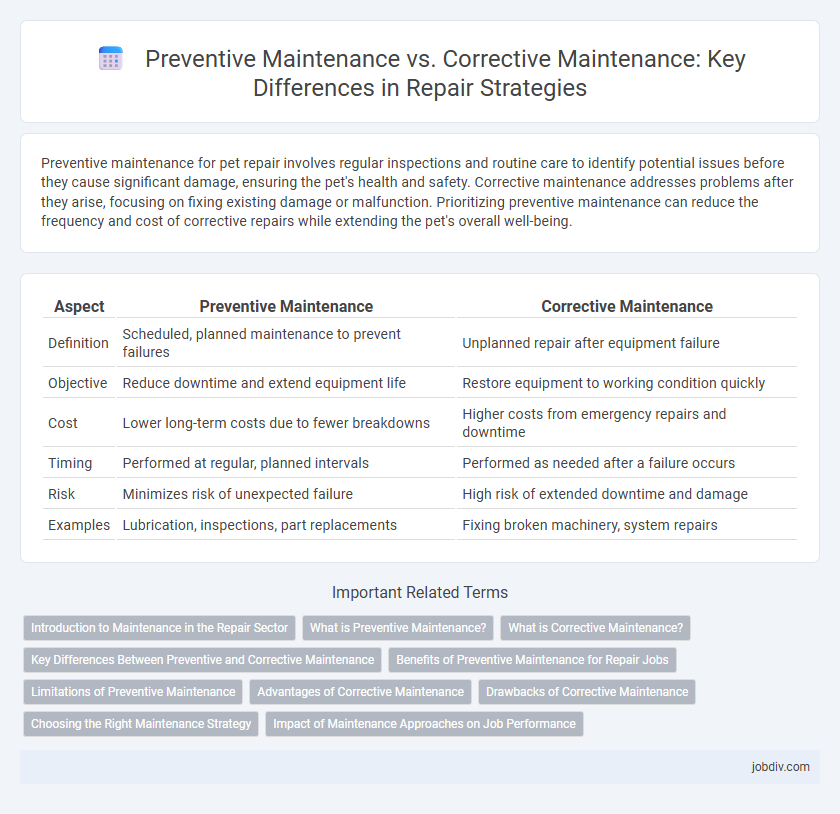

Preventive maintenance for pet repair involves regular inspections and routine care to identify potential issues before they cause significant damage, ensuring the pet's health and safety. Corrective maintenance addresses problems after they arise, focusing on fixing existing damage or malfunction. Prioritizing preventive maintenance can reduce the frequency and cost of corrective repairs while extending the pet's overall well-being.

Table of Comparison

| Aspect | Preventive Maintenance | Corrective Maintenance |

|---|---|---|

| Definition | Scheduled, planned maintenance to prevent failures | Unplanned repair after equipment failure |

| Objective | Reduce downtime and extend equipment life | Restore equipment to working condition quickly |

| Cost | Lower long-term costs due to fewer breakdowns | Higher costs from emergency repairs and downtime |

| Timing | Performed at regular, planned intervals | Performed as needed after a failure occurs |

| Risk | Minimizes risk of unexpected failure | High risk of extended downtime and damage |

| Examples | Lubrication, inspections, part replacements | Fixing broken machinery, system repairs |

Introduction to Maintenance in the Repair Sector

Preventive maintenance involves scheduled inspections and repairs to reduce equipment failures and extend asset life in the repair sector. Corrective maintenance addresses issues after equipment breakdowns, leading to higher downtime and repair costs. Implementing a balanced maintenance strategy enhances operational efficiency, minimizes unplanned interruptions, and optimizes resource allocation in industrial repair operations.

What is Preventive Maintenance?

Preventive maintenance involves scheduled inspections, adjustments, and replacements to reduce equipment failure and extend asset lifespan. This proactive approach addresses potential issues before they cause breakdowns, minimizing downtime and costly repairs. Key tasks include routine lubrication, cleaning, calibration, and part replacement based on manufacturer recommendations and usage patterns.

What is Corrective Maintenance?

Corrective maintenance involves repairing or restoring equipment and systems after a failure or malfunction occurs, aiming to return them to proper working condition. It addresses unplanned breakdowns, often resulting in downtime and potentially higher repair costs compared to scheduled upkeep. This reactive approach contrasts with preventive maintenance, which focuses on regular inspections and servicing to avoid unexpected failures.

Key Differences Between Preventive and Corrective Maintenance

Preventive maintenance involves routine inspections and scheduled servicing to reduce equipment failure and extend asset lifespan, while corrective maintenance is performed after a fault or breakdown occurs, focusing on repairing or replacing faulty components. Preventive maintenance prioritizes minimizing downtime and unexpected repairs through proactive measures, whereas corrective maintenance often results in reactive responses that can lead to increased operational disruptions and higher repair costs. Key differences also include cost implications, with preventive maintenance typically demanding consistent investment, whereas corrective maintenance can incur sporadic but potentially more expensive interventions.

Benefits of Preventive Maintenance for Repair Jobs

Preventive maintenance reduces equipment downtime by identifying and fixing potential issues before they escalate into major failures, ensuring continuous operation and reliability. It lowers overall repair costs by minimizing emergency repairs and extending the lifespan of machinery through regular inspections and servicing. This proactive approach enhances safety, optimizes performance, and improves asset management efficiency in repair jobs.

Limitations of Preventive Maintenance

Preventive maintenance often faces limitations such as inaccurate scheduling that may lead to unnecessary downtime or overlooked issues if maintenance intervals are too long. It can result in increased costs due to routine replacement of parts that may still be functional, reducing overall equipment efficiency. Furthermore, preventive maintenance may not address unexpected failures caused by sudden or unpredictable malfunctions, necessitating corrective maintenance.

Advantages of Corrective Maintenance

Corrective maintenance offers the advantage of addressing equipment failures only when they occur, reducing unnecessary downtime and maintenance costs associated with routine checks. It allows for immediate prioritization of critical repairs, ensuring resources are focused on actual issues rather than potential problems. This reactive approach can extend the lifecycle of machinery by avoiding over-maintenance and adapting repairs to real-time operational conditions.

Drawbacks of Corrective Maintenance

Corrective maintenance often leads to increased downtime and higher repair costs due to unexpected equipment failures. This approach can cause significant disruptions in production schedules and reduce overall operational efficiency. Relying solely on corrective maintenance increases the risk of severe damage, resulting in longer repair times and potential safety hazards.

Choosing the Right Maintenance Strategy

Choosing the right maintenance strategy involves evaluating equipment criticality, operational costs, and downtime impact to balance Preventive Maintenance and Corrective Maintenance effectively. Implementing Preventive Maintenance reduces unexpected failures and extends asset lifespan through scheduled inspections and servicing, while Corrective Maintenance addresses repairs only after malfunctions occur, often minimizing immediate expenses but risking longer downtimes. Data-driven analysis and predictive tools optimize decisions by forecasting failure probabilities and maintenance needs, ensuring reliable and cost-efficient operations.

Impact of Maintenance Approaches on Job Performance

Preventive maintenance improves job performance by reducing unexpected equipment failures and minimizing downtime, leading to increased operational efficiency. Corrective maintenance, while necessary for addressing breakdowns, often disrupts workflows and causes delays, negatively impacting productivity. Organizations prioritizing preventive strategies experience enhanced asset reliability and prolonged equipment lifespan, directly benefiting overall job performance.

Preventive Maintenance vs Corrective Maintenance Infographic

jobdiv.com

jobdiv.com