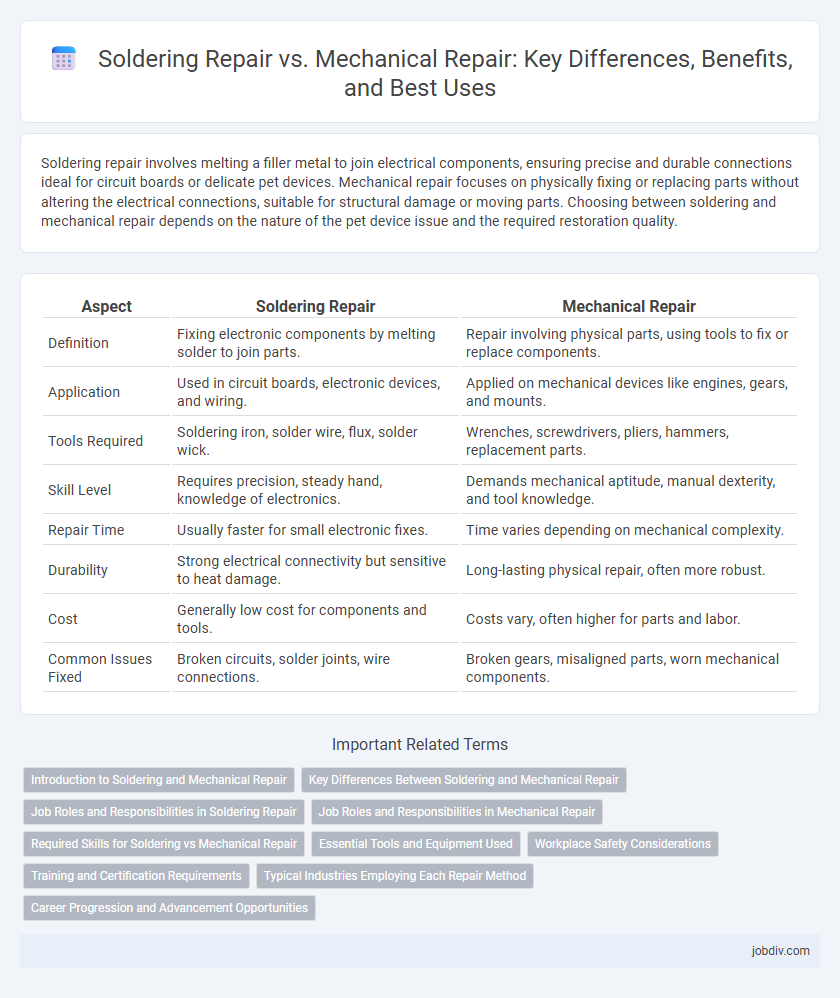

Soldering repair involves melting a filler metal to join electrical components, ensuring precise and durable connections ideal for circuit boards or delicate pet devices. Mechanical repair focuses on physically fixing or replacing parts without altering the electrical connections, suitable for structural damage or moving parts. Choosing between soldering and mechanical repair depends on the nature of the pet device issue and the required restoration quality.

Table of Comparison

| Aspect | Soldering Repair | Mechanical Repair |

|---|---|---|

| Definition | Fixing electronic components by melting solder to join parts. | Repair involving physical parts, using tools to fix or replace components. |

| Application | Used in circuit boards, electronic devices, and wiring. | Applied on mechanical devices like engines, gears, and mounts. |

| Tools Required | Soldering iron, solder wire, flux, solder wick. | Wrenches, screwdrivers, pliers, hammers, replacement parts. |

| Skill Level | Requires precision, steady hand, knowledge of electronics. | Demands mechanical aptitude, manual dexterity, and tool knowledge. |

| Repair Time | Usually faster for small electronic fixes. | Time varies depending on mechanical complexity. |

| Durability | Strong electrical connectivity but sensitive to heat damage. | Long-lasting physical repair, often more robust. |

| Cost | Generally low cost for components and tools. | Costs vary, often higher for parts and labor. |

| Common Issues Fixed | Broken circuits, solder joints, wire connections. | Broken gears, misaligned parts, worn mechanical components. |

Introduction to Soldering and Mechanical Repair

Soldering repair involves joining metal components by melting a filler metal to create a strong electrical and mechanical bond, commonly used in electronics and circuit board repairs. Mechanical repair relies on physical fastening methods such as screws, bolts, welding, or adhesives to restore structural integrity or functionality of mechanical parts. Understanding the fundamental differences between soldering and mechanical repair enhances the accuracy and durability of maintenance tasks across various industries.

Key Differences Between Soldering and Mechanical Repair

Soldering repair involves joining metal components using a molten alloy, providing electrical conductivity and permanent bonding, ideal for electronic circuits. Mechanical repair relies on physical fastening methods such as screws, bolts, or adhesives, offering structural support without electrical connection. Key differences include soldering's ability for seamless electrical integration versus mechanical repair's emphasis on mechanical strength and disassembly potential.

Job Roles and Responsibilities in Soldering Repair

Soldering repair technicians specialize in using soldering equipment to join electronic components, ensuring electrical continuity and mechanical stability on circuit boards. Their responsibilities include inspecting and diagnosing faulty connections, carefully applying solder to delicate parts, and performing rework to restore functionality without damaging surrounding components. This role demands precision, knowledge of electronic schematics, and proficiency with tools such as soldering irons, flux, and magnification devices to maintain high-quality repairs.

Job Roles and Responsibilities in Mechanical Repair

Mechanical repair technicians specialize in diagnosing, maintaining, and restoring mechanical systems using tools like wrenches, hammers, and diagnostic equipment. Their responsibilities include disassembling equipment, replacing worn components, aligning parts, and ensuring the mechanical integrity and functionality of machines. They focus on structural and mechanical issues, differentiating their role from soldering repair technicians who handle electronic circuit connections and component soldering.

Required Skills for Soldering vs Mechanical Repair

Soldering repair demands precise hand-eye coordination, proficiency in handling soldering irons, and an understanding of electronic components and circuit layouts. Mechanical repair requires skills in using hand and power tools, a grasp of mechanical systems, and the ability to troubleshoot physical wear or alignment issues. Both repair types necessitate technical knowledge, but soldering prioritizes fine motor skills and electrical expertise, while mechanical repair focuses on physical dexterity and mechanical problem-solving.

Essential Tools and Equipment Used

Soldering repair requires essential tools such as a temperature-controlled soldering iron, solder wire, flux, and desoldering pump to ensure precise component connections on circuit boards. Mechanical repair relies on specialized hand tools including screwdrivers, pliers, torque wrenches, and precision tweezers for disassembly and reassembly of physical parts. Both repair methods demand proper safety equipment like anti-static mats and protective eyewear to maintain quality and prevent damage.

Workplace Safety Considerations

Soldering repair involves exposure to high temperatures, fumes, and lead-based materials, necessitating the use of proper personal protective equipment (PPE) like heat-resistant gloves, fume extractors, and eye protection to prevent burns and inhalation hazards. Mechanical repair typically requires the handling of heavy tools and parts, increasing the risk of physical injury, so it is crucial to maintain ergonomic practices and use safety gear such as gloves, safety boots, and eye shields. Implementing rigorous safety protocols tailored to each repair type minimizes workplace accidents and promotes a safer repair environment.

Training and Certification Requirements

Soldering repair requires specialized training in electronics soldering techniques, thermal management, and precision handling, often certified through IPC-A-610 or J-STD-001 standards. Mechanical repair demands knowledge of mechanical systems, tools, and materials, with certifications like ASE or manufacturer-specific programs enhancing technician credibility. Both fields emphasize hands-on experience, but soldering repairs necessitate more stringent certification due to the precision and safety standards involved in electronic components.

Typical Industries Employing Each Repair Method

Electronics manufacturing and telecommunications industries primarily employ soldering repair for circuit board and delicate component restoration due to its precision and electrical connectivity. Mechanical repair is common in automotive, aerospace, and heavy machinery sectors where structural integrity and mechanical function are critical. Each method aligns with industry-specific demands for durability, performance, and operational safety.

Career Progression and Advancement Opportunities

Soldering repair skills open doors to specialized electronics and microelectronics roles, often leading to certifications and higher-paying technician positions. Mechanical repair expertise provides a broader foundation applicable across automotive, industrial, and machinery fields, enabling advancement into supervisory or engineering support roles. Career progression in soldering repair typically emphasizes precision and technical proficiency, while mechanical repair advancement favors diverse practical experience and problem-solving capabilities.

Soldering Repair vs Mechanical Repair Infographic

jobdiv.com

jobdiv.com