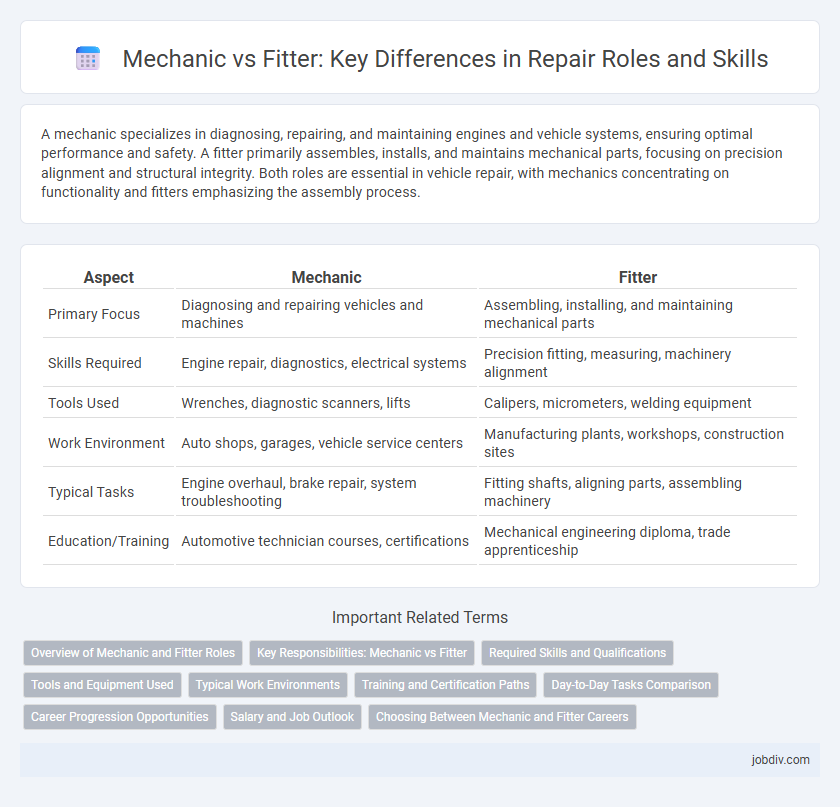

A mechanic specializes in diagnosing, repairing, and maintaining engines and vehicle systems, ensuring optimal performance and safety. A fitter primarily assembles, installs, and maintains mechanical parts, focusing on precision alignment and structural integrity. Both roles are essential in vehicle repair, with mechanics concentrating on functionality and fitters emphasizing the assembly process.

Table of Comparison

| Aspect | Mechanic | Fitter |

|---|---|---|

| Primary Focus | Diagnosing and repairing vehicles and machines | Assembling, installing, and maintaining mechanical parts |

| Skills Required | Engine repair, diagnostics, electrical systems | Precision fitting, measuring, machinery alignment |

| Tools Used | Wrenches, diagnostic scanners, lifts | Calipers, micrometers, welding equipment |

| Work Environment | Auto shops, garages, vehicle service centers | Manufacturing plants, workshops, construction sites |

| Typical Tasks | Engine overhaul, brake repair, system troubleshooting | Fitting shafts, aligning parts, assembling machinery |

| Education/Training | Automotive technician courses, certifications | Mechanical engineering diploma, trade apprenticeship |

Overview of Mechanic and Fitter Roles

Mechanics specialize in diagnosing, repairing, and maintaining vehicles and machinery, focusing on engine systems, electrical components, and mechanical assemblies. Fitters concentrate on assembling, installing, and aligning machinery parts, often working with metal components and structural frameworks to ensure precise fitting and operation. Both roles require technical skills, but mechanics emphasize troubleshooting and repair, while fitters prioritize fabrication and assembly accuracy.

Key Responsibilities: Mechanic vs Fitter

Mechanics specialize in diagnosing, repairing, and maintaining engines, hydraulic systems, and electrical components, ensuring optimal vehicle or machinery performance. Fitters focus on assembling, installing, and aligning mechanical parts, often working with blueprints and precision tools to construct or maintain industrial equipment. Both roles are essential in repair environments, with mechanics handling troubleshooting and repairs, while fitters concentrate on assembly and structural integrity.

Required Skills and Qualifications

Mechanics require strong diagnostic abilities, proficiency in automotive or machinery repair, and certifications such as ASE for vehicle mechanics. Fitters need mechanical aptitude, precision in reading blueprints, and expertise in installing, assembling, and maintaining metal structures or machine parts, often backed by trade apprenticeships or technical diplomas. Both roles demand problem-solving skills, but mechanics focus more on troubleshooting systems, while fitters emphasize fabrication and assembly accuracy.

Tools and Equipment Used

Mechanics primarily use diagnostic tools, wrenches, screwdrivers, and pneumatic equipment for vehicle repair and maintenance tasks. Fitters frequently work with precision measuring instruments, grinders, hammers, and alignment tools to assemble and adjust machinery or structural components. Both trades require specialized hand tools and safety gear, but the specific equipment varies significantly based on job functions.

Typical Work Environments

Mechanics typically work in automotive repair shops, manufacturing plants, and maintenance facilities, handling engines, transmissions, and electrical systems in vehicles and machinery. Fitters commonly operate in industrial settings such as factories, shipyards, and construction sites, specializing in assembling, installing, and aligning machinery and metal components. Both professions require hands-on work but differ in environments, with mechanics focusing more on diagnostic repairs and fitters on precision assembly tasks.

Training and Certification Paths

Mechanics typically undergo technical training programs focusing on engine repair, diagnostics, and automotive systems, often earning certifications from institutions like ASE (Automotive Service Excellence). Fitters receive specialized training in assembling and maintaining mechanical systems such as pipes, machinery, and heavy equipment, with certification options including those from the National Institute for Metalworking Skills (NIMS). Both career paths emphasize hands-on apprenticeships and continuous skill development to meet industry standards and ensure workplace safety.

Day-to-Day Tasks Comparison

Mechanics primarily diagnose, repair, and maintain engines, transmissions, and brake systems, relying on diagnostic tools and mechanical expertise to ensure vehicle performance. Fitters focus on assembling, installing, and aligning machinery and equipment parts within manufacturing or construction settings, emphasizing precision fitting and adjustments using hand and power tools. Both roles require strong technical skills, but mechanics work extensively with engine components, while fitters handle structural assembly and alignment tasks.

Career Progression Opportunities

Mechanics often advance by specializing in automotive diagnostics, engine repair, or becoming master mechanics with certifications that lead to supervisory roles. Fitters progress by mastering precision assembly, blueprint reading, and welding skills, enabling them to become lead fitters or workshop supervisors. Both careers offer pathways to technical instructor positions or management roles within manufacturing and maintenance industries.

Salary and Job Outlook

Mechanic positions typically offer a median salary ranging from $40,000 to $60,000 annually, with strong demand in automotive and industrial sectors driving steady job growth. Fitters earn slightly less on average, around $35,000 to $55,000 per year, but experience rising opportunities in manufacturing and construction industries due to infrastructure expansion. Both careers present positive job outlooks, though mechanics benefit from broader specialization options and higher wage potential.

Choosing Between Mechanic and Fitter Careers

Choosing between mechanic and fitter careers depends on your interest in either maintaining and repairing machinery or assembling and installing mechanical systems. Mechanics specialize in diagnosing and fixing issues in engines and vehicles, while fitters focus on aligning, assembling, and installing mechanical components in various industrial settings. Both careers require technical skills and problem-solving abilities, but mechanics often work with mobile equipment, whereas fitters typically operate in factory or construction environments.

Mechanic vs Fitter Infographic

jobdiv.com

jobdiv.com