Hand tool repairers specialize in the maintenance and restoration of manual tools such as hammers, screwdrivers, and pliers, emphasizing precision and mechanical knowledge. Power tool repairers focus on electric and battery-operated devices like drills, saws, and sanders, requiring expertise in electrical systems and motor components. Both roles demand strong troubleshooting skills and a deep understanding of tool mechanics to ensure effective and safe repairs.

Table of Comparison

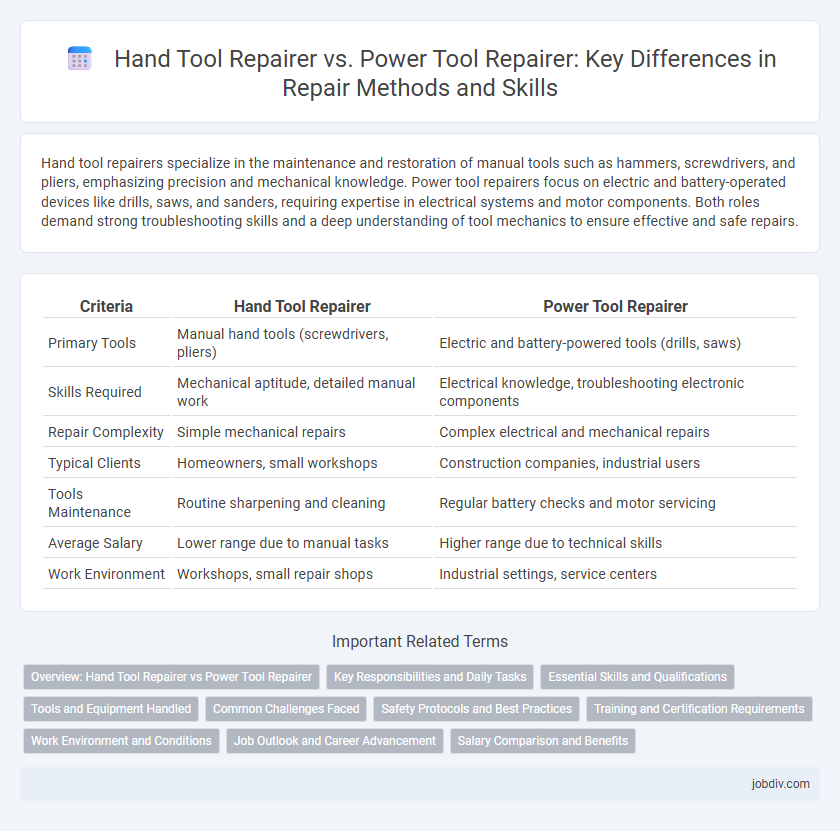

| Criteria | Hand Tool Repairer | Power Tool Repairer |

|---|---|---|

| Primary Tools | Manual hand tools (screwdrivers, pliers) | Electric and battery-powered tools (drills, saws) |

| Skills Required | Mechanical aptitude, detailed manual work | Electrical knowledge, troubleshooting electronic components |

| Repair Complexity | Simple mechanical repairs | Complex electrical and mechanical repairs |

| Typical Clients | Homeowners, small workshops | Construction companies, industrial users |

| Tools Maintenance | Routine sharpening and cleaning | Regular battery checks and motor servicing |

| Average Salary | Lower range due to manual tasks | Higher range due to technical skills |

| Work Environment | Workshops, small repair shops | Industrial settings, service centers |

Overview: Hand Tool Repairer vs Power Tool Repairer

Hand tool repairers specialize in maintaining and restoring manual tools such as hammers, screwdrivers, and wrenches, focusing on precision adjustments and component replacements. Power tool repairers handle electric or battery-operated tools like drills, saws, and sanders, requiring expertise in both mechanical and electrical diagnostics and repairs. Both roles demand technical skills but differ in the complexity and type of tools serviced, with power tool repairers often needing knowledge of circuitry and motor functions.

Key Responsibilities and Daily Tasks

Hand tool repairers specialize in maintaining, sharpening, and fixing manual tools such as hammers, screwdrivers, and pliers by inspecting wear, replacing parts, and ensuring functionality. Power tool repairers focus on diagnosing electrical and mechanical faults in devices like drills, saws, and grinders, testing motor performance, and replacing damaged components. Both roles require precise troubleshooting skills, use of specialized diagnostic equipment, and adherence to safety protocols in workshop settings.

Essential Skills and Qualifications

Hand tool repairers require strong mechanical aptitude, precision in manual dexterity, and expertise in sharpening and calibrating various hand tools. Power tool repairers need in-depth knowledge of electrical systems, proficiency in diagnosing motor and battery issues, and skills in soldering and circuit board repair. Both roles demand attention to detail, problem-solving abilities, and a commitment to safety standards.

Tools and Equipment Handled

Hand tool repairers primarily work on manual tools such as hammers, screwdrivers, pliers, and wrenches, focusing on sharpening, adjusting, and replacing broken parts. Power tool repairers specialize in electric and battery-operated equipment like drills, saws, and sanders, requiring knowledge of electrical systems, motors, and electronic components. Both roles demand distinct skill sets suited to the specific mechanical or electrical nature of the tools handled.

Common Challenges Faced

Hand tool repairers often encounter issues such as blade dullness, handle damage, and rust accumulation, requiring precise manual adjustments and replacements. Power tool repairers face challenges including motor failures, electrical wiring faults, and battery degradation, demanding advanced technical knowledge and diagnostic equipment. Both roles require steady hands, problem-solving skills, and an understanding of tool mechanics to restore functionality effectively.

Safety Protocols and Best Practices

Hand tool repairers prioritize wearing protective gloves and using insulated equipment to prevent cuts and electrical shocks, following strict lockout-tagout procedures to ensure tools are de-energized during maintenance. Power tool repairers implement comprehensive safety protocols, including using eye protection, grounding tools properly, and testing electrical components for faults to avoid accidents and malfunctions. Both roles emphasize regular inspection, proper calibration, and adherence to manufacturer guidelines to maintain tool integrity and ensure worker safety.

Training and Certification Requirements

Hand tool repairers typically require basic vocational training or on-the-job experience without formal certification, focusing on mechanical skills for wrenches, pliers, and hammers. Power tool repairers need more specialized training, often including technical certificates or associate degrees in electronics or mechanical repair, due to the complexity of electrical components in drills, saws, and grinders. Certification programs like those from the Electronics Technicians Association (ETA) or manufacturer-specific credentials enhance job prospects and demonstrate proficiency in power tool diagnostics and repair.

Work Environment and Conditions

Hand tool repairers typically work in well-lit workshops with limited noise and moderate physical activity, handling manual tools such as hammers and screwdrivers. Power tool repairers often operate in environments with higher noise levels due to motorized equipment, requiring the use of safety gear like ear protection and gloves to manage electrical and mechanical hazards. Both roles demand attention to detail and adherence to safety protocols, but power tool repairers face more intense physical and environmental risks linked to electric components and moving parts.

Job Outlook and Career Advancement

Hand tool repairers face steady demand driven by the continued use of manual tools in various trades, with job growth projected at 5% over the next decade. Power tool repairers experience faster job growth, around 7%, fueled by increasing reliance on electric and battery-operated devices across construction and manufacturing sectors. Career advancement for power tool repairers often involves specialization in advanced diagnostics and electronics, while hand tool repairers may progress through mastering diverse mechanical repairs and tool customization.

Salary Comparison and Benefits

Hand tool repairers typically earn an average annual salary ranging from $30,000 to $45,000, while power tool repairers can command higher wages, often between $40,000 and $60,000 due to the technical expertise required. Power tool repair professionals frequently receive additional benefits such as specialized training programs and certification reimbursements that enhance their career growth and job security. In contrast, hand tool repairers may have fewer formal training opportunities, but often benefit from more flexible work schedules and lower physical strain.

Hand Tool Repairer vs Power Tool Repairer Infographic

jobdiv.com

jobdiv.com