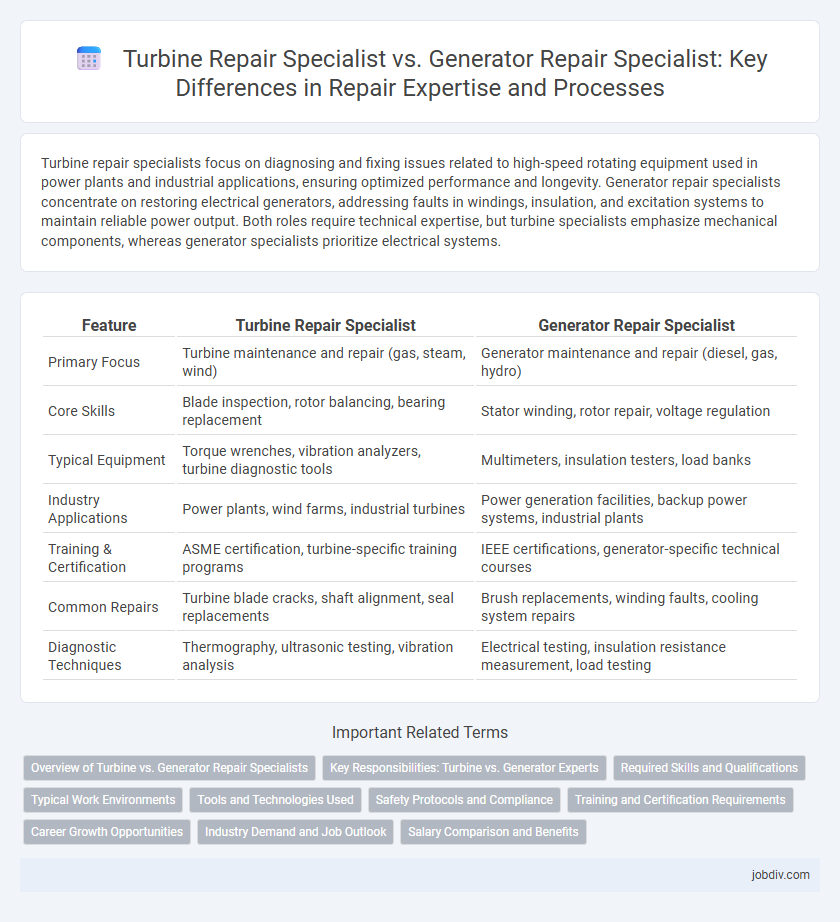

Turbine repair specialists focus on diagnosing and fixing issues related to high-speed rotating equipment used in power plants and industrial applications, ensuring optimized performance and longevity. Generator repair specialists concentrate on restoring electrical generators, addressing faults in windings, insulation, and excitation systems to maintain reliable power output. Both roles require technical expertise, but turbine specialists emphasize mechanical components, whereas generator specialists prioritize electrical systems.

Table of Comparison

| Feature | Turbine Repair Specialist | Generator Repair Specialist |

|---|---|---|

| Primary Focus | Turbine maintenance and repair (gas, steam, wind) | Generator maintenance and repair (diesel, gas, hydro) |

| Core Skills | Blade inspection, rotor balancing, bearing replacement | Stator winding, rotor repair, voltage regulation |

| Typical Equipment | Torque wrenches, vibration analyzers, turbine diagnostic tools | Multimeters, insulation testers, load banks |

| Industry Applications | Power plants, wind farms, industrial turbines | Power generation facilities, backup power systems, industrial plants |

| Training & Certification | ASME certification, turbine-specific training programs | IEEE certifications, generator-specific technical courses |

| Common Repairs | Turbine blade cracks, shaft alignment, seal replacements | Brush replacements, winding faults, cooling system repairs |

| Diagnostic Techniques | Thermography, ultrasonic testing, vibration analysis | Electrical testing, insulation resistance measurement, load testing |

Overview of Turbine vs. Generator Repair Specialists

Turbine repair specialists concentrate on maintaining and restoring components of turbines, such as blades, rotors, and housings, ensuring optimal mechanical performance under high-stress conditions. Generator repair specialists focus on the electrical and mechanical aspects of generators, including stators, rotors, and insulation systems, to sustain efficient power generation and prevent electrical faults. Both specialists require expertise in diagnostics, precision machining, and adherence to safety standards, but turbines demand more emphasis on thermal and aerodynamic considerations, whereas generators prioritize electrical integrity and magnetic properties.

Key Responsibilities: Turbine vs. Generator Experts

Turbine repair specialists focus on maintaining and restoring components such as blades, rotors, and bearings, ensuring optimal performance and efficiency of steam, gas, or wind turbines. Generator repair experts specialize in inspecting and fixing armatures, stators, and excitation systems to maintain reliable electrical power generation. Both roles require expertise in diagnosing mechanical and electrical faults but differ in their focus on rotating machinery versus electromagnetic components.

Required Skills and Qualifications

Turbine repair specialists require expertise in fluid dynamics, thermodynamics, and mechanical systems, along with certifications in turbine maintenance and safety protocols. Generator repair specialists must possess knowledge of electrical engineering, generator control systems, and diagnostics tools, often holding certifications in electrical safety and generator servicing. Both roles demand strong troubleshooting skills, experience with industrial machinery, and the ability to interpret technical manuals and blueprints.

Typical Work Environments

Turbine repair specialists typically work in power plants, industrial facilities, and offshore platforms where turbines are installed, often facing high-temperature and high-pressure environments. Generator repair specialists are commonly employed in power generation stations, manufacturing plants, and backup power facilities, dealing with electrical and mechanical components in controlled indoor settings. Both roles require adherence to strict safety protocols but differ significantly in the physical and technical conditions of their work environments.

Tools and Technologies Used

Turbine repair specialists utilize advanced diagnostic tools such as vibration analyzers, borescopes, and thermal imaging cameras to identify issues within turbine blades and rotors, relying heavily on precision machining equipment for component refurbishment. Generator repair specialists employ isolation transformers, insulation resistance testers, and surge generators to assess electrical integrity, using rewind machines and high-voltage test sets to restore stator windings and ensure optimal generator performance. Both fields integrate computerized monitoring systems and predictive maintenance software to enhance repair accuracy and prolong equipment lifespan.

Safety Protocols and Compliance

Turbine repair specialists adhere to rigorous safety protocols focused on high-speed rotating equipment, including strict lockout/tagout procedures and specialized personal protective equipment to prevent mechanical hazards and electrical shock. Generator repair specialists emphasize compliance with electrical safety standards such as NFPA 70E, ensuring grounding and insulation integrity to mitigate risks of arc flash and electrical faults. Both specialists must comply with OSHA regulations, but turbine repairs require additional attention to mechanical alignment and vibration monitoring for safe operation.

Training and Certification Requirements

Turbine repair specialists typically require extensive training in mechanical and thermal systems, often holding certifications such as AWS (American Welding Society) or NDT (Non-Destructive Testing) to handle high-precision turbine components safely. Generator repair specialists focus on electrical and mechanical systems, usually obtaining certifications like NCCER (National Center for Construction Education and Research) or OSHA (Occupational Safety and Health Administration) to ensure compliance with electrical safety standards. Both roles demand rigorous hands-on experience and ongoing education to stay current with evolving technologies and industry regulations.

Career Growth Opportunities

Turbine repair specialists experience strong career growth driven by the increasing demand for efficient energy solutions and the specialized skill set required to maintain complex turbine systems. Generator repair specialists benefit from consistent advancement opportunities due to the widespread reliance on generators across various industries and the evolving technology in power generation. Both careers offer pathways to senior technical roles, management positions, and opportunities in renewable energy sectors.

Industry Demand and Job Outlook

Turbine repair specialists are in high demand within the renewable energy and power generation sectors due to increasing investments in wind and gas turbines, while generator repair specialists maintain strong job prospects driven by consistent industrial and commercial reliance on backup power systems. Growth projections for turbine repair technicians are expected to outpace general machinery repair roles, reflecting the shift toward cleaner energy technologies. Both roles require specialized skills, but turbine repair positions typically offer higher wages and more opportunities owing to the complexity and technological advancements in turbine machinery.

Salary Comparison and Benefits

Turbine repair specialists typically earn higher salaries than generator repair specialists, with median annual wages ranging from $70,000 to $90,000 compared to $60,000 to $80,000 for generator specialists, reflecting the advanced technical skills required for turbine maintenance. Benefits for turbine repair roles often include specialized training programs, certifications, and opportunities for overtime pay due to the critical nature of power generation equipment. Generator repair specialists may have more consistent work hours and broader opportunities in residential and commercial sectors, offering stability and diverse work environments.

Turbine Repair Specialist vs Generator Repair Specialist Infographic

jobdiv.com

jobdiv.com