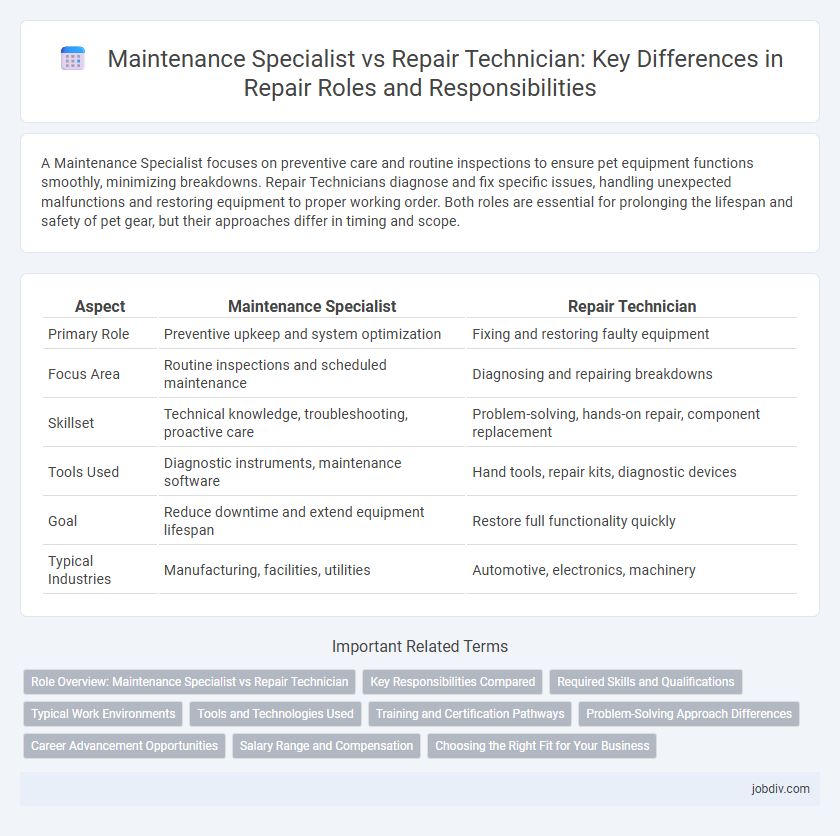

A Maintenance Specialist focuses on preventive care and routine inspections to ensure pet equipment functions smoothly, minimizing breakdowns. Repair Technicians diagnose and fix specific issues, handling unexpected malfunctions and restoring equipment to proper working order. Both roles are essential for prolonging the lifespan and safety of pet gear, but their approaches differ in timing and scope.

Table of Comparison

| Aspect | Maintenance Specialist | Repair Technician |

|---|---|---|

| Primary Role | Preventive upkeep and system optimization | Fixing and restoring faulty equipment |

| Focus Area | Routine inspections and scheduled maintenance | Diagnosing and repairing breakdowns |

| Skillset | Technical knowledge, troubleshooting, proactive care | Problem-solving, hands-on repair, component replacement |

| Tools Used | Diagnostic instruments, maintenance software | Hand tools, repair kits, diagnostic devices |

| Goal | Reduce downtime and extend equipment lifespan | Restore full functionality quickly |

| Typical Industries | Manufacturing, facilities, utilities | Automotive, electronics, machinery |

Role Overview: Maintenance Specialist vs Repair Technician

A Maintenance Specialist focuses on preventive measures, ensuring equipment operates efficiently through regular inspections and scheduled upkeep. A Repair Technician primarily addresses breakdowns by diagnosing malfunctions and restoring machinery to working order. Both roles are critical in minimizing downtime and maintaining operational continuity in industrial environments.

Key Responsibilities Compared

Maintenance Specialists oversee preventive maintenance programs, ensuring machinery operates efficiently through regular inspections and scheduled servicing. Repair Technicians focus on diagnosing and fixing equipment malfunctions promptly to minimize downtime and restore functionality. Both roles require technical expertise, but Maintenance Specialists emphasize proactive upkeep while Repair Technicians specialize in reactive troubleshooting and repairs.

Required Skills and Qualifications

Maintenance specialists require expertise in preventive maintenance, mechanical systems, and diagnostic techniques, often holding certifications such as HVAC or electrical licenses. Repair technicians focus on troubleshooting, repairing equipment, and hands-on technical skills with proficiency in tools and machinery, typically supported by technical diplomas or apprenticeships. Both roles demand strong problem-solving abilities, attention to detail, and knowledge of safety standards in industrial or commercial settings.

Typical Work Environments

Maintenance Specialists typically work in manufacturing plants, commercial facilities, and large industrial settings, ensuring routine upkeep and system inspections. Repair Technicians often operate in diverse environments such as residential homes, automotive shops, and electronic service centers, focusing on troubleshooting and fixing specific equipment failures. Both roles require adaptability to varied conditions but differ in the scale and scope of their work environments.

Tools and Technologies Used

Maintenance specialists utilize diagnostic software, computerized maintenance management systems (CMMS), and predictive analytics tools to monitor equipment health and perform preventive upkeep. Repair technicians primarily rely on hand tools, power tools, oscilloscopes, multimeters, and welding equipment to troubleshoot and fix mechanical or electrical faults. Both roles integrate emerging technologies like IoT sensors and augmented reality for enhanced accuracy and efficiency in their tasks.

Training and Certification Pathways

Maintenance specialists typically pursue certifications such as Certified Maintenance & Reliability Professional (CMRP) or Mechanical Maintenance Technician certifications, emphasizing preventive maintenance and system optimization training. Repair technicians often obtain certifications like HVAC Excellence, ASE Automotive Technician, or Electrical Technician credentials, focusing on diagnostic, troubleshooting, and hands-on repair skills. Training pathways for maintenance specialists prioritize comprehensive equipment knowledge and reliability engineering, while repair technicians gain specialized expertise in specific systems or machinery repairs.

Problem-Solving Approach Differences

Maintenance specialists focus on preventive strategies, analyzing system performance data to identify potential issues before failures occur, ensuring equipment reliability. Repair technicians prioritize diagnosing and fixing immediate malfunctions using hands-on troubleshooting techniques and tools. Their problem-solving approaches differ as specialists emphasize long-term system optimization, while technicians concentrate on timely restoration of operational functionality.

Career Advancement Opportunities

Maintenance specialists often have broader career advancement opportunities due to their expertise in preventive strategies and systems management, positioning them for supervisory or managerial roles. Repair technicians typically focus on hands-on troubleshooting and fixing equipment, which can lead to specialization in specific technologies or certification-based career growth. Both career paths offer progression, but maintenance specialists may access higher-level positions that require strategic planning and resource coordination skills.

Salary Range and Compensation

Maintenance Specialists typically earn between $45,000 and $70,000 annually, reflecting their expertise in preventive upkeep and system optimization. Repair Technicians' salaries range from $40,000 to $65,000, based on their technical skills in diagnosing and fixing mechanical or electrical issues. Compensation packages for both roles often include benefits such as overtime pay, bonuses, and health insurance, influencing total earnings significantly.

Choosing the Right Fit for Your Business

Maintenance specialists concentrate on preventive upkeep to avoid equipment failures, enhancing operational efficiency and reducing downtime. Repair technicians focus on diagnosing and fixing machinery breakdowns, restoring functionality swiftly to minimize production interruptions. Choosing the right fit depends on your business needs: prioritize maintenance specialists for long-term system reliability and repair technicians for addressing immediate mechanical issues.

Maintenance Specialist vs Repair Technician Infographic

jobdiv.com

jobdiv.com