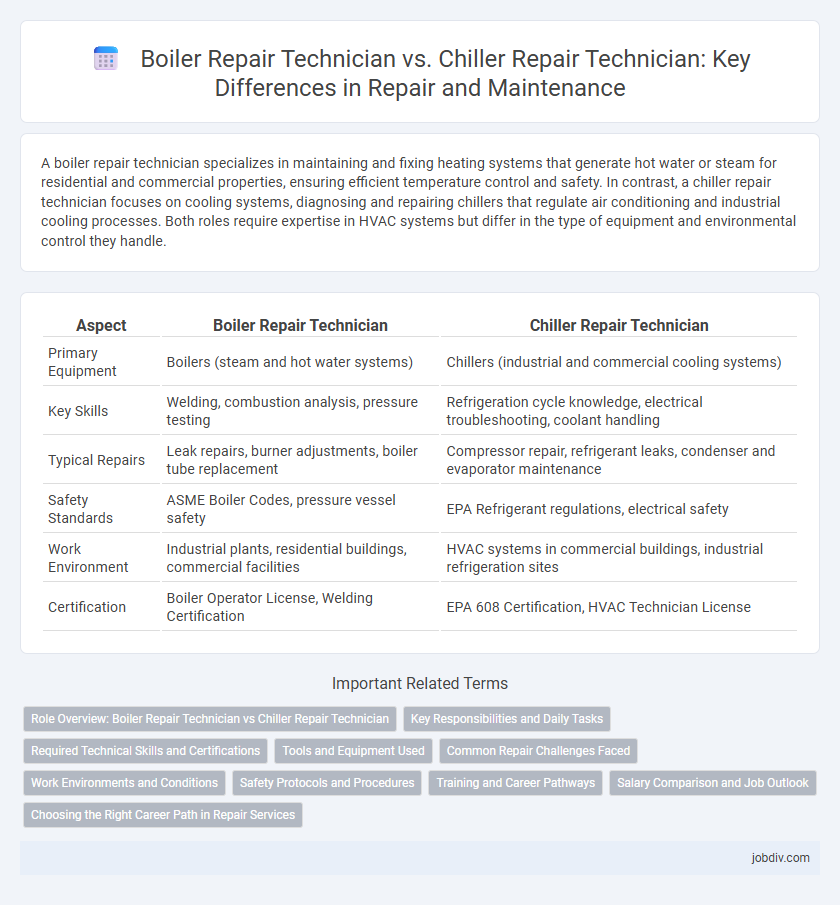

A boiler repair technician specializes in maintaining and fixing heating systems that generate hot water or steam for residential and commercial properties, ensuring efficient temperature control and safety. In contrast, a chiller repair technician focuses on cooling systems, diagnosing and repairing chillers that regulate air conditioning and industrial cooling processes. Both roles require expertise in HVAC systems but differ in the type of equipment and environmental control they handle.

Table of Comparison

| Aspect | Boiler Repair Technician | Chiller Repair Technician |

|---|---|---|

| Primary Equipment | Boilers (steam and hot water systems) | Chillers (industrial and commercial cooling systems) |

| Key Skills | Welding, combustion analysis, pressure testing | Refrigeration cycle knowledge, electrical troubleshooting, coolant handling |

| Typical Repairs | Leak repairs, burner adjustments, boiler tube replacement | Compressor repair, refrigerant leaks, condenser and evaporator maintenance |

| Safety Standards | ASME Boiler Codes, pressure vessel safety | EPA Refrigerant regulations, electrical safety |

| Work Environment | Industrial plants, residential buildings, commercial facilities | HVAC systems in commercial buildings, industrial refrigeration sites |

| Certification | Boiler Operator License, Welding Certification | EPA 608 Certification, HVAC Technician License |

Role Overview: Boiler Repair Technician vs Chiller Repair Technician

Boiler repair technicians specialize in diagnosing, maintaining, and repairing steam and hot water boilers to ensure safe and efficient operation in heating systems. Chiller repair technicians focus on troubleshooting and fixing refrigeration systems that remove heat from large buildings or industrial processes, ensuring optimal cooling performance. Both roles require expertise in mechanical systems, safety protocols, and regular maintenance, but the boiler technician primarily handles heat generation equipment while the chiller technician manages thermal cooling units.

Key Responsibilities and Daily Tasks

Boiler Repair Technicians specialize in maintaining, diagnosing, and fixing boilers to ensure optimal heating system performance and safety compliance. Chiller Repair Technicians focus on troubleshooting and repairing industrial and commercial chillers, handling refrigerant systems, compressors, and heat exchangers to maintain efficient cooling. Both technicians perform regular inspections, preventive maintenance, and emergency repairs, but their expertise centers on different HVAC components and operational systems.

Required Technical Skills and Certifications

Boiler Repair Technicians require expertise in combustion systems, pressure vessel regulations, and knowledge of ASME Boiler and Pressure Vessel Codes, often holding certifications such as HVAC certification and boiler operator licenses. Chiller Repair Technicians need proficiency in refrigeration cycles, electrical diagnostics, and coolant handling, with certifications including EPA 608 Universal Certification and HVAC Excellence credentials. Both roles demand strong mechanical and electrical troubleshooting skills, but their specialized certifications and technical knowledge differ according to the specific systems they maintain.

Tools and Equipment Used

Boiler repair technicians primarily use tools such as pipe wrenches, pressure gauges, combustion analyzers, and multimeters to diagnose and fix heating systems. Chiller repair technicians rely on specialized equipment like refrigerant recovery machines, manifold gauge sets, leak detectors, and vacuum pumps to service cooling systems efficiently. Both professionals require safety gear and diagnostic instruments but differ in the technical tools tailored to their specific heating or cooling units.

Common Repair Challenges Faced

Boiler repair technicians frequently encounter challenges such as addressing corrosion damage, fixing faulty pressure valves, and diagnosing complex fuel system issues, which require specialized knowledge of combustion processes and heat exchange principles. Chiller repair technicians often face difficulties with refrigerant leaks, malfunctioning compressors, and electrical control faults, demanding expertise in refrigeration cycles and HVAC systems. Both roles necessitate adapting to evolving technology and ensuring compliance with safety regulations to maintain optimal equipment performance.

Work Environments and Conditions

Boiler repair technicians typically work in industrial plants, commercial buildings, and residential settings, often facing high temperatures, confined spaces, and exposure to steam and hot water hazards. Chiller repair technicians operate in environments such as data centers, hospitals, and large commercial facilities, dealing with refrigerants, electrical components, and maintaining temperature-controlled systems. Both roles require adherence to strict safety protocols, but boiler technicians encounter more extreme heat conditions, while chiller technicians manage risks related to refrigerants and electrical safety.

Safety Protocols and Procedures

Boiler repair technicians follow strict safety protocols including pressure testing, gas leak detection, and personal protective equipment (PPE) to prevent burns, explosions, and carbon monoxide poisoning. Chiller repair technicians prioritize procedures such as refrigerant handling regulations, electrical hazard precautions, and confined space entry protocols to avoid toxic exposure and electrocution. Both roles require adherence to industry standards, regular safety training, and the use of calibrated diagnostic tools to ensure operational safety and efficiency.

Training and Career Pathways

Boiler repair technicians typically undergo specialized training in combustion systems, pressure vessels, and heating controls, often requiring certifications like the National Board Commissioned Boiler Inspector (NBCBI) credential. Chiller repair technicians focus on refrigeration cycles, HVAC systems, and electrical diagnostics, with pathways including EPA certification for handling refrigerants and HVAC Excellence credentials. Career advancement for boiler technicians often leads to roles in industrial maintenance management, while chiller technicians may progress to HVAC system design or energy management positions.

Salary Comparison and Job Outlook

Boiler repair technicians earn an average salary of $55,000 to $70,000 annually, reflecting steady demand in residential and industrial heating systems maintenance. Chiller repair technicians typically command higher salaries, ranging from $60,000 to $80,000, due to specialized skills required for commercial HVAC systems and refrigeration units. Job growth for both professions is expected to remain stable over the next decade, with chiller repair technicians seeing slightly stronger demand driven by expanding commercial construction and energy efficiency regulations.

Choosing the Right Career Path in Repair Services

Boiler repair technicians specialize in maintaining and fixing heating systems, focusing on high-pressure boilers used in residential and industrial settings, while chiller repair technicians concentrate on refrigeration and cooling systems crucial for HVAC and industrial processes. Selecting the right career path depends on understanding the technical demands, work environments, and industry growth, with boiler technicians often working in construction and manufacturing, and chiller technicians serving commercial and industrial cooling sectors. Both roles require strong mechanical skills, certification, and safety knowledge, but career advancement and specialization vary based on regional demand and technological developments in heating versus cooling technologies.

Boiler Repair Technician vs Chiller Repair Technician Infographic

jobdiv.com

jobdiv.com