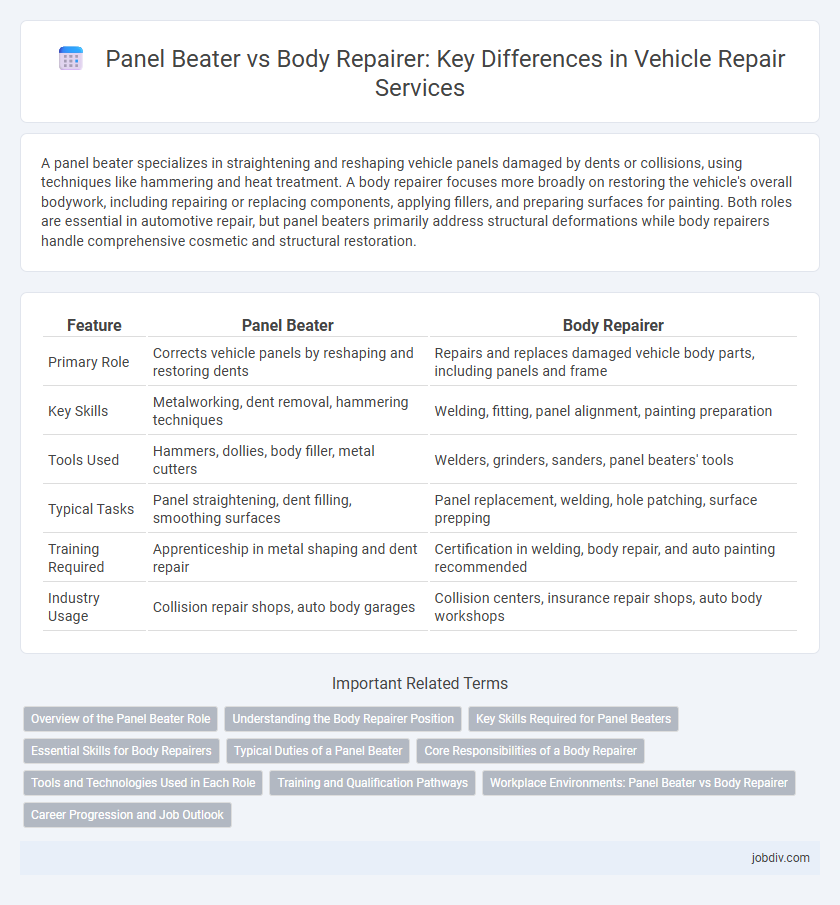

A panel beater specializes in straightening and reshaping vehicle panels damaged by dents or collisions, using techniques like hammering and heat treatment. A body repairer focuses more broadly on restoring the vehicle's overall bodywork, including repairing or replacing components, applying fillers, and preparing surfaces for painting. Both roles are essential in automotive repair, but panel beaters primarily address structural deformations while body repairers handle comprehensive cosmetic and structural restoration.

Table of Comparison

| Feature | Panel Beater | Body Repairer |

|---|---|---|

| Primary Role | Corrects vehicle panels by reshaping and restoring dents | Repairs and replaces damaged vehicle body parts, including panels and frame |

| Key Skills | Metalworking, dent removal, hammering techniques | Welding, fitting, panel alignment, painting preparation |

| Tools Used | Hammers, dollies, body filler, metal cutters | Welders, grinders, sanders, panel beaters' tools |

| Typical Tasks | Panel straightening, dent filling, smoothing surfaces | Panel replacement, welding, hole patching, surface prepping |

| Training Required | Apprenticeship in metal shaping and dent repair | Certification in welding, body repair, and auto painting recommended |

| Industry Usage | Collision repair shops, auto body garages | Collision centers, insurance repair shops, auto body workshops |

Overview of the Panel Beater Role

A panel beater specializes in restoring vehicle bodies by reshaping, repairing, or replacing damaged panels caused by collisions or wear. This role demands expertise in metalworking, welding, and paint preparation to ensure structural integrity and aesthetic quality. Panel beaters work closely with body repairers but focus primarily on the precise restoration of vehicle panels.

Understanding the Body Repairer Position

A Body Repairer specializes in restoring the structural integrity and appearance of vehicle bodies by repairing dents, scratches, and damaged panels using techniques like welding and filler application. Unlike a Panel Beater who mainly reshapes and aligns metal panels, the Body Repairer performs detailed surface preparations and finishing tasks to ensure a smooth, paint-ready surface. Proficiency in using power tools, sanding equipment, and paint removal methods is essential for a Body Repairer to achieve high-quality repairs and maintain the vehicle's safety standards.

Key Skills Required for Panel Beaters

Panel beaters require advanced skills in metalworking to reshape vehicle frames damaged by collisions, using tools such as hammers, dollies, and welders to restore structural integrity. Expertise in measuring and aligning chassis components ensures precise repairs that meet safety standards. Mastery of paint stripping and surface preparation techniques enhances the quality of finished bodywork, distinguishing their role from general body repairers.

Essential Skills for Body Repairers

Body repairers must excel in metalworking, welding, and surface finishing to restore vehicle exteriors precisely. Proficiency in identifying structural damage and using specialized tools for dent removal and panel alignment is critical. Strong attention to detail and knowledge of automotive materials ensure high-quality repairs and durability.

Typical Duties of a Panel Beater

A panel beater specializes in reshaping, repairing, and replacing damaged vehicle body parts such as panels, doors, and bumpers. They use tools like hammers, dollies, and paintless dent removal techniques to restore the vehicle's original shape and structural integrity. Typical duties also include welding, sanding, and prepping surfaces for painting to ensure a seamless finish.

Core Responsibilities of a Body Repairer

A body repairer specializes in restoring vehicle bodywork by removing dents, replacing damaged panels, and ensuring proper alignment for structural integrity. They use advanced tools like welding equipment, grinders, and fillers to meticulously repair and reshape metal surfaces. Core responsibilities include assessing damage extent, preparing surfaces for painting, and collaborating with technicians to meet safety and aesthetic standards.

Tools and Technologies Used in Each Role

Panel beaters utilize traditional hand tools such as hammers, dollies, and sanding blocks for reshaping and smoothing metal surfaces, often combined with pneumatic machines and welding equipment to restore vehicle panels. Body repairers employ advanced technologies like computerized paint-matching systems, frame straightening machines, and diagnostic tools for electronic system repairs, enhancing precision and efficiency in restoring vehicles after collisions. Both roles require proficiency in specialized equipment, but body repairers integrate more digital and electronic tools to address modern vehicle complexities.

Training and Qualification Pathways

Panel Beaters typically undergo formal apprenticeships lasting 3 to 4 years, where they learn metal shaping, welding, and dent repair techniques, often leading to nationally recognized certifications such as the National Institute for Automotive Service Excellence (ASE). Body Repairers focus on broader skills including paint application and structural repairs, with training pathways that include trade school programs and on-the-job experience, culminating in qualifications like the I-CAR (Inter-Industry Conference on Auto Collision Repair) certification. Both roles require continuous education to stay updated with evolving vehicle materials and repair technologies.

Workplace Environments: Panel Beater vs Body Repairer

Panel beaters typically work in highly specialized workshops equipped with heavy-duty tools for reshaping and straightening vehicle panels, often involving welding and metalwork under controlled indoor environments. Body repairers operate in diverse settings that include auto body shops and collision repair centers, where the focus is on fixing cosmetic damage, sanding, and applying fillers and paint, requiring well-ventilated spaces to handle chemical fumes. Both professions demand adherence to safety protocols but differ in spatial layout and equipment according to the nature of metal fabrication versus surface restoration tasks.

Career Progression and Job Outlook

Panel beaters typically advance by specializing in complex metal shaping techniques and may progress to roles like workshop supervisor or quality assessor, benefiting from a steady demand in automotive repair. Body repairers often diversify skills in welding, painting, and damage assessment, opening opportunities in accident repair centers and restoration projects with a positive job outlook driven by increased vehicle ownership and insurance claims. Both careers require ongoing training to adapt to new automotive technologies, enhancing employability and growth potential in the collision repair industry.

Panel Beater vs Body Repairer Infographic

jobdiv.com

jobdiv.com