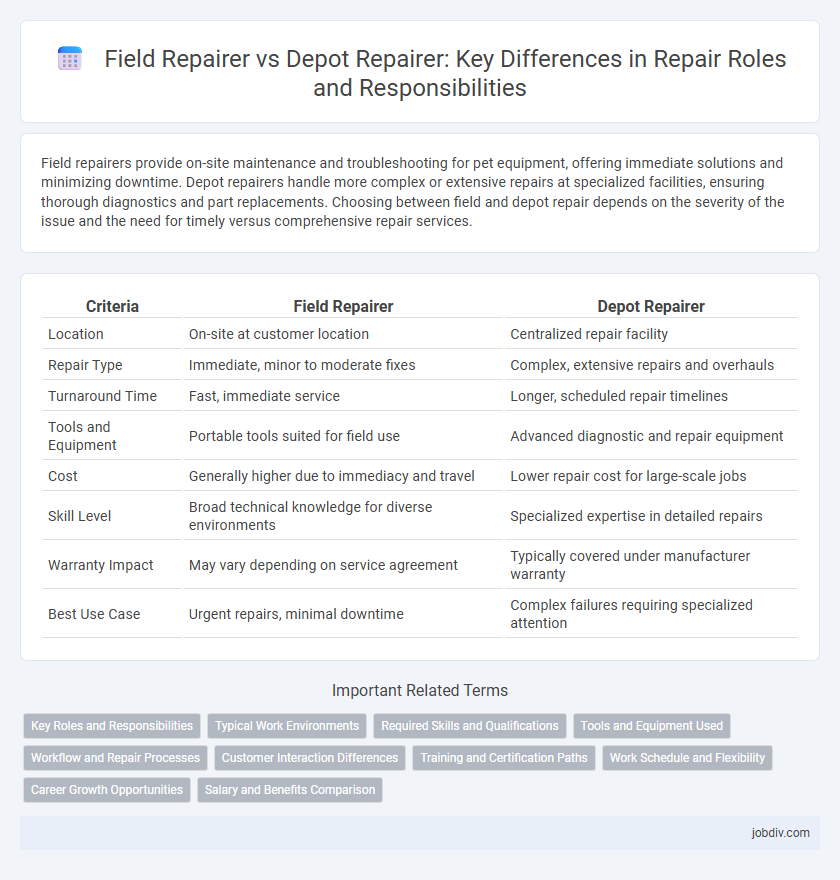

Field repairers provide on-site maintenance and troubleshooting for pet equipment, offering immediate solutions and minimizing downtime. Depot repairers handle more complex or extensive repairs at specialized facilities, ensuring thorough diagnostics and part replacements. Choosing between field and depot repair depends on the severity of the issue and the need for timely versus comprehensive repair services.

Table of Comparison

| Criteria | Field Repairer | Depot Repairer |

|---|---|---|

| Location | On-site at customer location | Centralized repair facility |

| Repair Type | Immediate, minor to moderate fixes | Complex, extensive repairs and overhauls |

| Turnaround Time | Fast, immediate service | Longer, scheduled repair timelines |

| Tools and Equipment | Portable tools suited for field use | Advanced diagnostic and repair equipment |

| Cost | Generally higher due to immediacy and travel | Lower repair cost for large-scale jobs |

| Skill Level | Broad technical knowledge for diverse environments | Specialized expertise in detailed repairs |

| Warranty Impact | May vary depending on service agreement | Typically covered under manufacturer warranty |

| Best Use Case | Urgent repairs, minimal downtime | Complex failures requiring specialized attention |

Key Roles and Responsibilities

Field repairers specialize in on-site troubleshooting, diagnostics, and immediate repairs to minimize downtime, often handling urgent hardware and software issues directly at customer locations. Depot repairers operate in centralized facilities, performing detailed component-level repairs, refurbishments, and testing to restore equipment to factory standards, ensuring quality control and inventory management. Both roles require technical expertise, but field repairers emphasize rapid, on-the-spot service while depot repairers focus on comprehensive, in-depth maintenance and equipment refurbishment.

Typical Work Environments

Field Repairers typically operate on-site at client locations, industrial plants, or outdoor environments where immediate troubleshooting and repairs are crucial to minimizing downtime. Depot Repairers work within centralized repair facilities equipped with specialized diagnostic tools and controlled environments to handle complex and detailed component overhauls. The distinction in work environments influences the skill sets required, with Field Repairers emphasizing adaptability and rapid response, while Depot Repairers focus on precision and comprehensive equipment restoration.

Required Skills and Qualifications

Field Repairers require strong problem-solving skills, extensive hands-on experience, and the ability to work independently in diverse environments, often needing certifications in troubleshooting and equipment repair. Depot Repairers typically need advanced technical qualifications, proficiency with diagnostic tools, and expertise in detailed component-level repair, emphasizing precision and adherence to standardized procedures. Both roles demand strong communication skills and the capacity to interpret technical manuals, but Field Repairers prioritize adaptability while Depot Repairers focus on in-depth technical knowledge.

Tools and Equipment Used

Field repairers utilize portable diagnostic tools, handheld multimeters, and compact soldering kits to perform on-site equipment troubleshooting and repairs efficiently. Depot repairers rely on advanced bench tools such as precision oscilloscopes, large-scale testing rigs, and specialized calibration instruments designed for comprehensive diagnostics and component-level refurbishments. Toolsets for field repair emphasize mobility and quick fixes, while depot repairs involve extensive, high-precision equipment supporting in-depth restoration processes.

Workflow and Repair Processes

Field Repairers execute on-site repairs, enabling immediate troubleshooting and minimal equipment downtime by diagnosing issues directly at the client's location. Depot Repairers manage centralized repair facilities with specialized tools and controlled environments, facilitating complex diagnostics, component replacements, and extensive testing. The workflow for Field Repairers prioritizes rapid response and mobility, whereas Depot Repairers emphasize thorough repair processes and quality assurance before returning equipment to service.

Customer Interaction Differences

Field Repairers directly engage with customers at their locations, providing immediate troubleshooting and repair services that enhance customer satisfaction through personalized and timely support. Depot Repairers operate within repair centers, managing customer issues remotely, which limits face-to-face interaction but allows for specialized, centralized diagnostics and part replacements. The nature of field repair emphasizes real-time communication and on-site problem resolution, whereas depot repair focuses on efficiency and expertise in a controlled environment.

Training and Certification Paths

Field repairers undergo specialized on-site training emphasizing troubleshooting and immediate equipment restoration, often requiring certifications like CompTIA A+ or manufacturer-specific credentials to validate their practical skills. Depot repairers receive comprehensive training in advanced diagnostics, component-level repairs, and system overhauls within controlled environments, typically earning certifications such as IPC J-STD-001 or vendor-endorsed factory technician programs. Both paths demand continuous education to keep pace with evolving technologies and maintain compliance with industry standards.

Work Schedule and Flexibility

Field repairers often have irregular work schedules due to on-site visits and emergency calls, requiring high flexibility and availability. Depot repairers typically work fixed hours in controlled environments, allowing for predictable schedules but less flexibility. The nature of field repair demands adaptability to varied locations and timings, contrasting with the routine and stability found in depot repair roles.

Career Growth Opportunities

Field repairers gain hands-on experience in diverse environments, enhancing problem-solving skills and adaptability crucial for advancement in technical roles. Depot repairers work in controlled settings, allowing specialization in complex diagnostics and in-depth equipment knowledge, which supports progression into senior technician or supervisory positions. Career growth for both paths can lead to roles in quality control, training, or management depending on technical expertise and leadership abilities.

Salary and Benefits Comparison

Field repairers typically earn higher hourly wages compared to depot repairers due to travel demands and on-site responsibilities, with average salaries ranging from $45,000 to $65,000 annually. Depot repairers often receive more comprehensive benefits packages, including health insurance, retirement plans, and paid leave, benefiting from a stable, indoor work environment. While field repairers enjoy premium pay and travel allowances, depot repairers gain better job security and structured advancement opportunities within repair facilities.

Field Repairer vs Depot Repairer Infographic

jobdiv.com

jobdiv.com