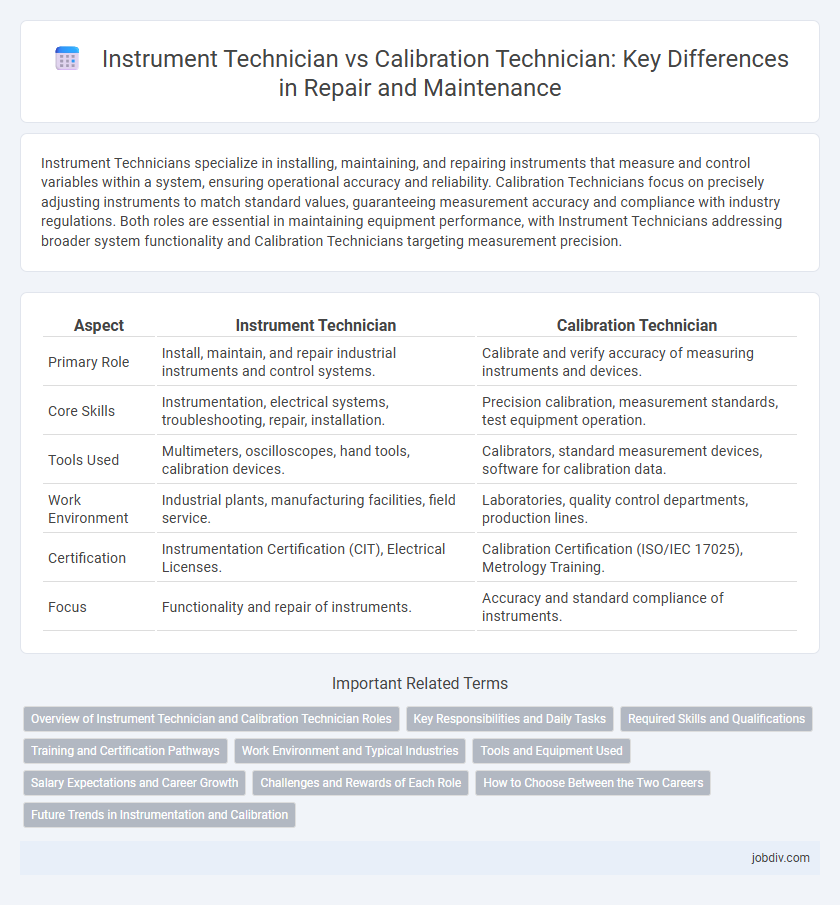

Instrument Technicians specialize in installing, maintaining, and repairing instruments that measure and control variables within a system, ensuring operational accuracy and reliability. Calibration Technicians focus on precisely adjusting instruments to match standard values, guaranteeing measurement accuracy and compliance with industry regulations. Both roles are essential in maintaining equipment performance, with Instrument Technicians addressing broader system functionality and Calibration Technicians targeting measurement precision.

Table of Comparison

| Aspect | Instrument Technician | Calibration Technician |

|---|---|---|

| Primary Role | Install, maintain, and repair industrial instruments and control systems. | Calibrate and verify accuracy of measuring instruments and devices. |

| Core Skills | Instrumentation, electrical systems, troubleshooting, repair, installation. | Precision calibration, measurement standards, test equipment operation. |

| Tools Used | Multimeters, oscilloscopes, hand tools, calibration devices. | Calibrators, standard measurement devices, software for calibration data. |

| Work Environment | Industrial plants, manufacturing facilities, field service. | Laboratories, quality control departments, production lines. |

| Certification | Instrumentation Certification (CIT), Electrical Licenses. | Calibration Certification (ISO/IEC 17025), Metrology Training. |

| Focus | Functionality and repair of instruments. | Accuracy and standard compliance of instruments. |

Overview of Instrument Technician and Calibration Technician Roles

Instrument Technicians specialize in installing, maintaining, and repairing complex instrumentation and control systems used in industries like manufacturing, oil and gas, and pharmaceuticals. Calibration Technicians focus on testing, adjusting, and ensuring the accuracy of measurement instruments and devices, adhering to strict standards and regulatory requirements. Both roles require expertise in troubleshooting and technical knowledge, but Instrument Technicians handle broader system functions while Calibration Technicians concentrate on precision measurement validation.

Key Responsibilities and Daily Tasks

Instrument Technicians specialize in installing, maintaining, and troubleshooting electronic and mechanical instruments used in industrial processes. Calibration Technicians focus on verifying and adjusting the accuracy of measurement instruments, ensuring compliance with industry standards and regulations. Both roles require precision and technical expertise, with Instrument Technicians handling broader equipment maintenance and Calibration Technicians concentrating on measurement accuracy and calibration documentation.

Required Skills and Qualifications

Instrument Technicians need a strong foundation in electrical systems, mechanical troubleshooting, and proficiency with PLCs (Programmable Logic Controllers) to maintain and repair industrial instruments effectively. Calibration Technicians require expertise in precision measurement, understanding of calibration standards, and skills in using calibrators and diagnostic tools to ensure instruments meet regulatory accuracy requirements. Both roles demand technical certifications, such as an associate degree in instrumentation or calibration technology, and hands-on experience with industry-specific equipment and software.

Training and Certification Pathways

Instrument Technicians often require comprehensive training in instrumentation, electrical systems, and control theory, with certifications like ISA Certified Control Systems Technician (CCST) enhancing their credentials. Calibration Technicians typically focus on precision measurement techniques and calibration standards, earning certifications such as the National Institute for Standards and Technology (NIST) calibration accreditation. Both roles benefit from technical diplomas or associate degrees, but Instrument Technicians usually undergo broader industrial training, while Calibration Technicians specialize in metrology and standard compliance.

Work Environment and Typical Industries

Instrument Technicians typically work in industrial plants, manufacturing facilities, and energy sectors, where they handle the installation, maintenance, and repair of instrumentation systems. Calibration Technicians are often found in laboratories, aerospace, pharmaceuticals, and quality control environments, focusing on ensuring precise measurements by calibrating instruments and devices. Both roles require technical expertise but differ in work settings, with Instrument Technicians operating in field or plant environments and Calibration Technicians primarily working in controlled indoor settings.

Tools and Equipment Used

Instrument Technicians primarily use multimeters, oscilloscopes, and signal generators to troubleshoot and repair electronic control systems. Calibration Technicians rely on precision calibrators, pressure gauges, and reference standards to ensure measurement instruments meet regulatory accuracy requirements. Both roles require specialized diagnostic tools, but Calibration Technicians emphasize instruments that verify and adjust device outputs within specified tolerances.

Salary Expectations and Career Growth

Instrument Technicians typically earn an average salary ranging from $55,000 to $75,000 annually, with opportunities for advancement into senior technical or supervisory roles within industrial maintenance sectors. Calibration Technicians generally have a salary range of $50,000 to $70,000, with career growth often leading to specialized positions in quality assurance or metrology. Both roles offer stable career paths, but Instrument Technicians may experience broader demand across manufacturing, oil and gas, and engineering industries, influencing higher salary potential and diverse advancement opportunities.

Challenges and Rewards of Each Role

Instrument Technicians face challenges such as diagnosing complex electronic and mechanical issues while ensuring precise functionality of control systems, which rewards them with high demand skills in automation industries. Calibration Technicians encounter the challenge of maintaining accuracy and compliance with rigorous industry standards, rewarding them with critical roles in quality assurance and regulatory adherence. Both roles require meticulous attention to detail, but Instrument Technicians often gain broader troubleshooting experience, whereas Calibration Technicians build specialized expertise in measurement accuracy.

How to Choose Between the Two Careers

When choosing between an Instrument Technician and a Calibration Technician career, consider your interest in hands-on equipment maintenance versus precision measurement and adjustment. Instrument Technicians specialize in installing and repairing control instruments, ensuring operational reliability in industrial settings. Calibration Technicians focus on verifying and adjusting instruments to meet exact standards, making them essential for quality control and compliance roles.

Future Trends in Instrumentation and Calibration

Instrumentation and calibration technicians are increasingly embracing automation and digitalization, with smart sensors and IoT integration transforming traditional maintenance and calibration processes. The adoption of predictive analytics and machine learning enhances real-time diagnostics, reducing downtime and improving accuracy in both instrument repair and calibration tasks. Future trends emphasize the need for technicians to develop advanced skills in data analytics, cybersecurity, and remote monitoring technologies to keep pace with evolving industrial requirements.

Instrument Technician vs Calibration Technician Infographic

jobdiv.com

jobdiv.com