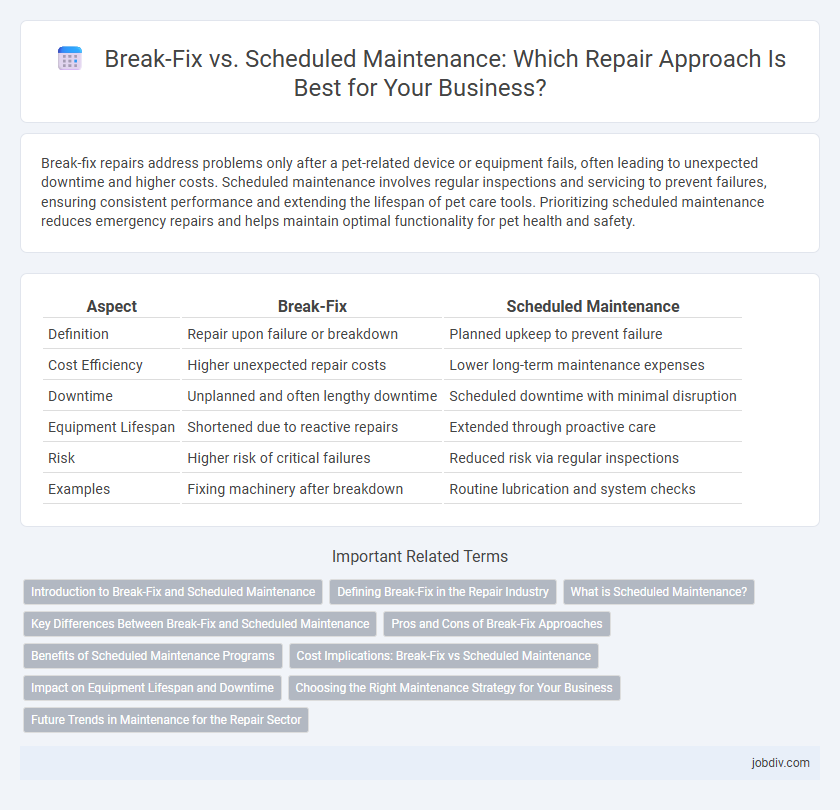

Break-fix repairs address problems only after a pet-related device or equipment fails, often leading to unexpected downtime and higher costs. Scheduled maintenance involves regular inspections and servicing to prevent failures, ensuring consistent performance and extending the lifespan of pet care tools. Prioritizing scheduled maintenance reduces emergency repairs and helps maintain optimal functionality for pet health and safety.

Table of Comparison

| Aspect | Break-Fix | Scheduled Maintenance |

|---|---|---|

| Definition | Repair upon failure or breakdown | Planned upkeep to prevent failure |

| Cost Efficiency | Higher unexpected repair costs | Lower long-term maintenance expenses |

| Downtime | Unplanned and often lengthy downtime | Scheduled downtime with minimal disruption |

| Equipment Lifespan | Shortened due to reactive repairs | Extended through proactive care |

| Risk | Higher risk of critical failures | Reduced risk via regular inspections |

| Examples | Fixing machinery after breakdown | Routine lubrication and system checks |

Introduction to Break-Fix and Scheduled Maintenance

Break-Fix is a reactive repair strategy where equipment is fixed only after a failure occurs, often resulting in unexpected downtime and higher emergency repair costs. Scheduled Maintenance involves regular, planned inspections and servicing designed to prevent breakdowns and extend the lifespan of machinery. Implementing Scheduled Maintenance reduces the risk of costly repairs by addressing wear and tear before it leads to equipment failure.

Defining Break-Fix in the Repair Industry

Break-fix in the repair industry refers to the reactive approach of fixing equipment or systems only after a malfunction or failure occurs. This strategy emphasizes addressing immediate issues without prior scheduling, often resulting in longer downtimes and emergency costs. Effective break-fix management relies on rapid diagnosis and repair to restore operational functionality as quickly as possible.

What is Scheduled Maintenance?

Scheduled maintenance is a proactive approach that involves routinely inspecting, servicing, and replacing parts on equipment or systems to prevent unexpected breakdowns and extend their lifespan. This planned strategy minimizes downtime and reduces costly emergency repairs by addressing potential issues before they escalate. Regularly scheduled maintenance optimizes performance and ensures compliance with manufacturer guidelines and safety standards.

Key Differences Between Break-Fix and Scheduled Maintenance

Break-fix repair involves fixing equipment only after a failure occurs, often resulting in unexpected downtime and higher emergency costs. Scheduled maintenance proactively services machinery at regular intervals to prevent breakdowns, enhance longevity, and improve operational efficiency. Key differences include cost predictability, downtime frequency, and the strategic approach to equipment reliability.

Pros and Cons of Break-Fix Approaches

Break-fix repair approaches offer the advantage of addressing issues only when they arise, reducing upfront maintenance costs and minimizing unnecessary service interventions. However, this reactive strategy can lead to unpredictable downtime, higher emergency repair expenses, and potential damage escalation due to delayed detection of faults. Organizations adopting break-fix models face challenges in maintaining consistent system reliability and may incur greater long-term operational disruptions compared to preventative maintenance schedules.

Benefits of Scheduled Maintenance Programs

Scheduled maintenance programs reduce downtime by proactively identifying and addressing potential issues before they cause failures, improving equipment reliability and extending asset lifespan. These programs optimize operational efficiency and lower long-term repair costs by preventing unexpected breakdowns. Consistent upkeep through scheduled maintenance also enhances safety and compliance with industry standards, minimizing risks associated with equipment malfunction.

Cost Implications: Break-Fix vs Scheduled Maintenance

Break-fix repair often incurs higher costs due to unexpected equipment failures and emergency service fees, leading to unplanned downtime and lost productivity. Scheduled maintenance reduces overall expenses by preventing major breakdowns through regular inspections and timely parts replacement, optimizing operational efficiency. Investing in preventive maintenance plans typically results in lower total cost of ownership compared to reactive break-fix solutions.

Impact on Equipment Lifespan and Downtime

Break-fix repair leads to unpredictable downtime and often shortens equipment lifespan due to delayed issue detection and reactive fixes. Scheduled maintenance proactively identifies and resolves wear and tear, extending equipment life and minimizing unplanned outages. Consistent maintenance schedules improve operational efficiency by reducing emergency repairs and equipment failures.

Choosing the Right Maintenance Strategy for Your Business

Break-fix maintenance addresses equipment failures after they occur, leading to unpredictable downtime and higher emergency repair costs, while scheduled maintenance involves regular inspections and proactive servicing to prevent breakdowns and extend asset lifespan. Businesses seeking to optimize operational efficiency and reduce unplanned expenses should analyze equipment criticality, failure patterns, and budget constraints to determine the ideal balance between reactive repairs and preventive maintenance. Implementing a data-driven maintenance strategy enhances reliability, minimizes disruptions, and supports long-term cost savings.

Future Trends in Maintenance for the Repair Sector

Future trends in maintenance for the repair sector emphasize predictive analytics and IoT integration to minimize reliance on traditional break-fix models by enabling real-time equipment monitoring. Scheduled maintenance is evolving into condition-based maintenance, reducing downtime through data-driven decision-making and automated diagnostics. Enhanced AI-powered tools and augmented reality support technicians in proactive repairs, improving efficiency and asset longevity.

Break-Fix vs Scheduled Maintenance Infographic

jobdiv.com

jobdiv.com