Asset repair involves fixing existing equipment to restore functionality, often resulting in cost savings and reduced downtime compared to asset replacement. Choosing repair over replacement extends the life of valuable assets and minimizes environmental impact by reducing waste. However, replacement becomes necessary when repair costs exceed the value of the asset or when equipment is outdated and inefficient.

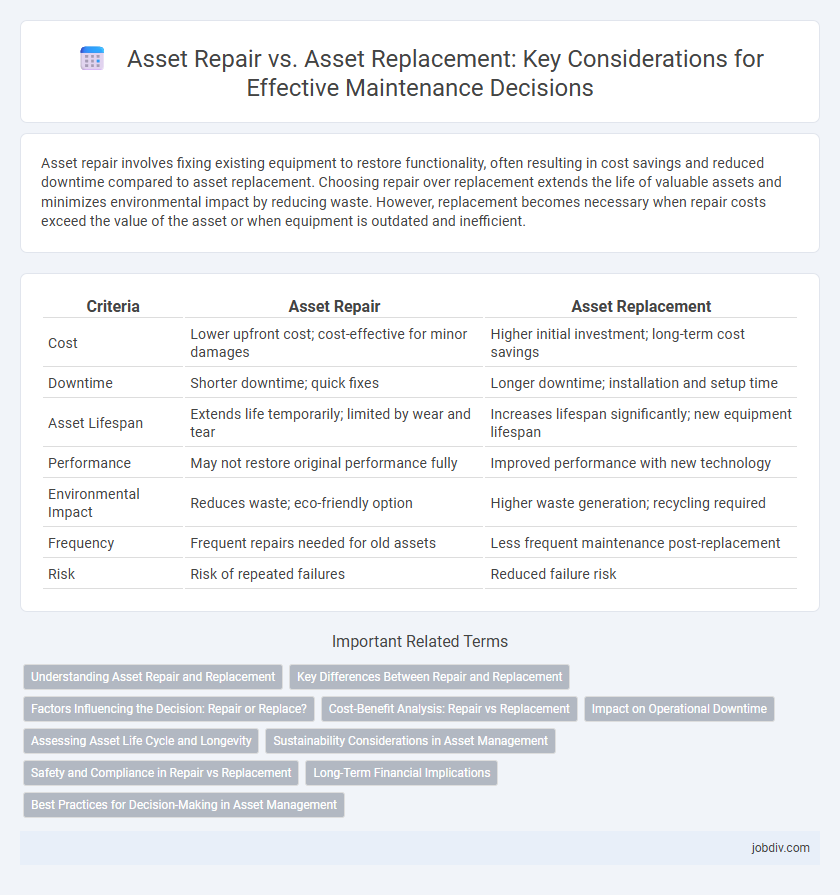

Table of Comparison

| Criteria | Asset Repair | Asset Replacement |

|---|---|---|

| Cost | Lower upfront cost; cost-effective for minor damages | Higher initial investment; long-term cost savings |

| Downtime | Shorter downtime; quick fixes | Longer downtime; installation and setup time |

| Asset Lifespan | Extends life temporarily; limited by wear and tear | Increases lifespan significantly; new equipment lifespan |

| Performance | May not restore original performance fully | Improved performance with new technology |

| Environmental Impact | Reduces waste; eco-friendly option | Higher waste generation; recycling required |

| Frequency | Frequent repairs needed for old assets | Less frequent maintenance post-replacement |

| Risk | Risk of repeated failures | Reduced failure risk |

Understanding Asset Repair and Replacement

Asset repair involves maintaining and restoring existing equipment to extend its operational life, which often reduces immediate costs and downtime. Replacement entails investing in new assets to improve performance, reliability, and efficiency, often justified when repair costs exceed a certain threshold. Evaluating factors like asset age, repair frequency, and overall cost helps optimize decisions between repair and replacement strategies.

Key Differences Between Repair and Replacement

Asset repair involves restoring existing equipment to operational condition, typically costing less and requiring shorter downtime compared to replacement. Asset replacement entails procuring new equipment, often delivering improved performance and reliability but incurring higher initial investment and longer integration time. Key differences include cost implications, impact on operational continuity, and potential for technological upgrades.

Factors Influencing the Decision: Repair or Replace?

Evaluating asset repair versus replacement involves analyzing key factors such as the asset's age, repair costs, and expected lifespan post-repair. High repair expenses approaching asset replacement value and frequent breakdowns often signal replacement as a more cost-effective solution. Assessing operational downtime impact and technological advancements ensures informed decisions aligning with budget constraints and performance goals.

Cost-Benefit Analysis: Repair vs Replacement

Cost-benefit analysis in asset repair versus replacement involves evaluating the total expenses of fixing existing equipment against the acquisition and installation costs of new assets. Repair often reduces immediate outlays by extending equipment life but may increase maintenance expenses and downtime over time. Replacement offers higher upfront costs while potentially improving operational efficiency and reducing long-term maintenance, necessitating a detailed financial comparison based on asset age, performance, and reliability metrics.

Impact on Operational Downtime

Asset repair significantly reduces operational downtime by restoring equipment functionality without the extended lead times required for replacement procurement and installation. Repair processes often involve faster turnaround times, minimizing disruption and maintaining productivity levels in critical operations. Conversely, asset replacement typically results in longer downtime due to removal, new asset delivery, and integration, which can severely impact operational efficiency.

Assessing Asset Life Cycle and Longevity

Assessing asset life cycle and longevity is crucial for determining whether to pursue asset repair or complete replacement. Repairing extends the functional lifespan of equipment by addressing specific faults, often resulting in cost savings and reduced downtime compared to replacement. Evaluating factors such as the asset's current condition, maintenance history, and projected future performance ensures informed decisions that optimize operational efficiency and capital expenditure.

Sustainability Considerations in Asset Management

Asset repair conserves resources by extending the lifespan of existing equipment, reducing waste and lowering the environmental impact associated with manufacturing new assets. Prioritizing repair over replacement minimizes carbon emissions and supports circular economy principles in asset management. Sustainable asset management strategies leverage repair to optimize resource efficiency and align with long-term environmental goals.

Safety and Compliance in Repair vs Replacement

Asset repair prioritizes maintaining safety and compliance by adhering to industry standards and ensuring all repairs meet regulatory requirements, reducing the risk of operational hazards. Replacement may introduce new components that are factory-certified and compliant but involves downtime and potential installation errors that could compromise safety. Consistent inspection and documentation during repair processes help organizations uphold safety protocols and regulatory compliance efficiently.

Long-Term Financial Implications

Asset repair offers cost savings by extending the lifecycle of equipment and reducing immediate capital expenditures, while asset replacement often involves higher upfront costs but can lead to lower maintenance expenses and improved operational efficiency over time. Evaluating the total cost of ownership, including repairs, downtime, energy efficiency, and residual value, is critical for making informed long-term financial decisions. Strategic asset management balances repair and replacement expenses to optimize budget allocation and maximize return on investment.

Best Practices for Decision-Making in Asset Management

Evaluating the total cost of ownership, including repair expenses, downtime, and life expectancy, is crucial for making informed asset management decisions. Implement predictive maintenance technologies and real-time monitoring to assess asset condition and optimize timing for repairs or replacements. Prioritize sustainability and regulatory compliance by considering environmental impact and asset performance standards when choosing between repair and replacement.

Asset Repair vs Asset Replacement Infographic

jobdiv.com

jobdiv.com