Line Repair involves fixing minor issues quickly on the spot, minimizing downtime and keeping pets comfortable, while Bench Repair is ideal for more complex problems requiring specialized tools and detailed attention. Choosing Line Repair speeds up the process for routine fixes such as leash repairs or small tears, whereas Bench Repair tackles extensive damage like broken harnesses or structural frame issues. Prioritizing the repair type ensures pets receive safe, durable solutions tailored to their specific needs.

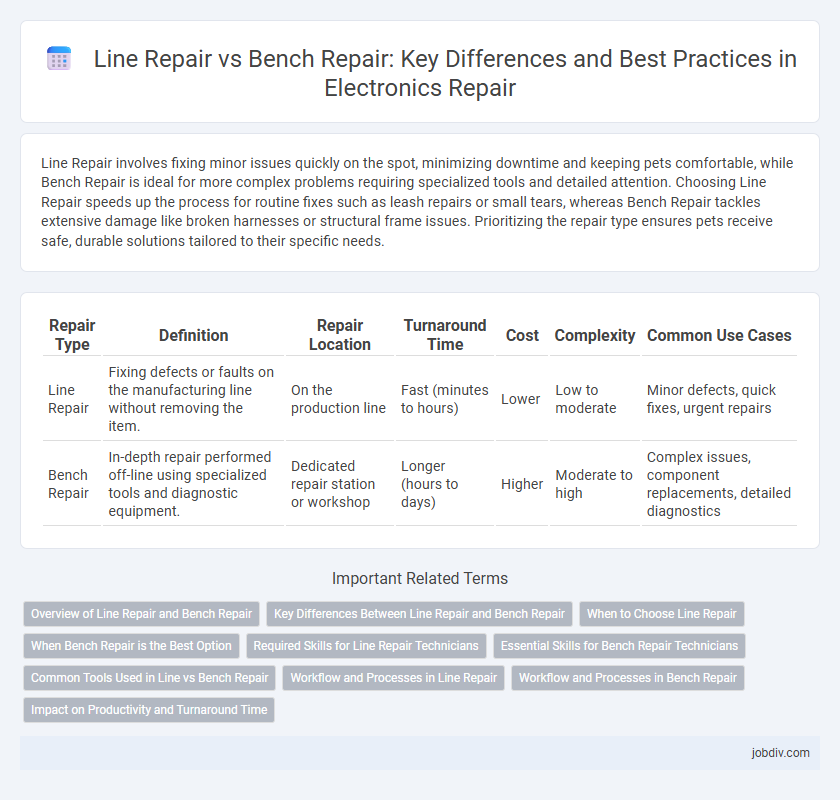

Table of Comparison

| Repair Type | Definition | Repair Location | Turnaround Time | Cost | Complexity | Common Use Cases |

|---|---|---|---|---|---|---|

| Line Repair | Fixing defects or faults on the manufacturing line without removing the item. | On the production line | Fast (minutes to hours) | Lower | Low to moderate | Minor defects, quick fixes, urgent repairs |

| Bench Repair | In-depth repair performed off-line using specialized tools and diagnostic equipment. | Dedicated repair station or workshop | Longer (hours to days) | Higher | Moderate to high | Complex issues, component replacements, detailed diagnostics |

Overview of Line Repair and Bench Repair

Line repair involves fixing equipment directly at its operational site, minimizing downtime by addressing issues quickly without disassembly. Bench repair requires removing the equipment and conducting detailed diagnostics and repairs in a controlled workshop environment, enabling thorough maintenance of complex components. Selecting between line and bench repair depends on the severity of the malfunction and the need for specialized tools or parts.

Key Differences Between Line Repair and Bench Repair

Line repair involves maintenance and minor fixes performed directly on the equipment or vehicle without disassembly, enabling quick turnaround times and minimal disruption. Bench repair requires the removal of components for detailed inspection, cleaning, and comprehensive repairs on a workbench, ideal for complex issues that cannot be resolved in the field. The key differences include the scope of repair, time investment, and whether the equipment remains operational during service.

When to Choose Line Repair

Line repair is ideal when equipment requires minimal downtime and quick fixes, as it can be performed directly on the production floor without dismantling. This method suits minor defects, routine maintenance, or adjustments that do not necessitate complete disassembly, thereby reducing operational disruptions. Choosing line repair enhances efficiency by addressing issues swiftly, preserving workflow continuity and minimizing repair costs compared to bench repair.

When Bench Repair is the Best Option

Bench repair is the best option when electronic devices require intricate component-level diagnostics and replacements that cannot be effectively handled on the production line. It allows for a controlled environment with specialized tools and skilled technicians to address complex faults, such as PCB rework or micro-soldering. This method ensures higher precision and reliability for delicate repairs compared to line repair processes.

Required Skills for Line Repair Technicians

Line repair technicians require strong diagnostic and troubleshooting skills to quickly identify and resolve equipment issues on-site, minimizing downtime. Proficiency in using portable testing tools and a solid understanding of system components and operational procedures are essential for effective line repair. Adaptability and the ability to work safely in variable environments also distinguish line repair specialists from bench repair technicians.

Essential Skills for Bench Repair Technicians

Bench repair technicians require precise diagnostic skills, proficiency in soldering and circuit board repair, and a deep understanding of electronic component functionality. Mastery of multimeter usage, schematic reading, and software troubleshooting is essential for efficiently restoring device performance. Strong attention to detail and steady hands enable technicians to address intricate hardware failures and ensure high-quality repairs.

Common Tools Used in Line vs Bench Repair

Line repair typically involves portable tools such as oscilloscopes, multimeters, soldering irons, and hand tools like screwdrivers and pliers designed for quick diagnosis and minor fixes on-site. Bench repair, performed in a controlled workshop environment, utilizes more specialized equipment including power supplies, component testers, reflow ovens, and precision soldering stations for detailed circuit board repairs. The choice of tools directly reflects the complexity and location of the repair task, with line repair emphasizing mobility and speed, while bench repair focuses on precision and thorough testing.

Workflow and Processes in Line Repair

Line repair emphasizes rapid diagnostics and fixes performed directly on the production floor to minimize equipment downtime and maintain continuous operations. Technicians follow streamlined workflows that prioritize quick component replacements, real-time testing, and immediate adjustments without removing equipment from the line. This process reduces turnaround time and supports ongoing productivity compared to the more extensive disassembly and detailed inspection typical of bench repair.

Workflow and Processes in Bench Repair

Bench repair workflows focus on detailed diagnostics, precision component replacement, and extensive testing within a controlled environment, enabling higher accuracy and quality assurance compared to line repair. The process involves disassembling equipment at the bench level for thorough inspection, utilizing specialized tools and calibration devices to identify and rectify faults. This method emphasizes meticulous step-by-step procedures, ensuring all parts meet stringent standards before reassembly and final functional verification.

Impact on Productivity and Turnaround Time

Line repair minimizes equipment downtime by addressing issues directly on the production floor, significantly improving productivity. Bench repair, while often more thorough, involves removing equipment for off-site service, leading to longer turnaround times and potential operational delays. Choosing line repair enhances workflow continuity, whereas bench repair may be necessary for complex faults requiring specialized tools.

Line Repair vs Bench Repair Infographic

jobdiv.com

jobdiv.com