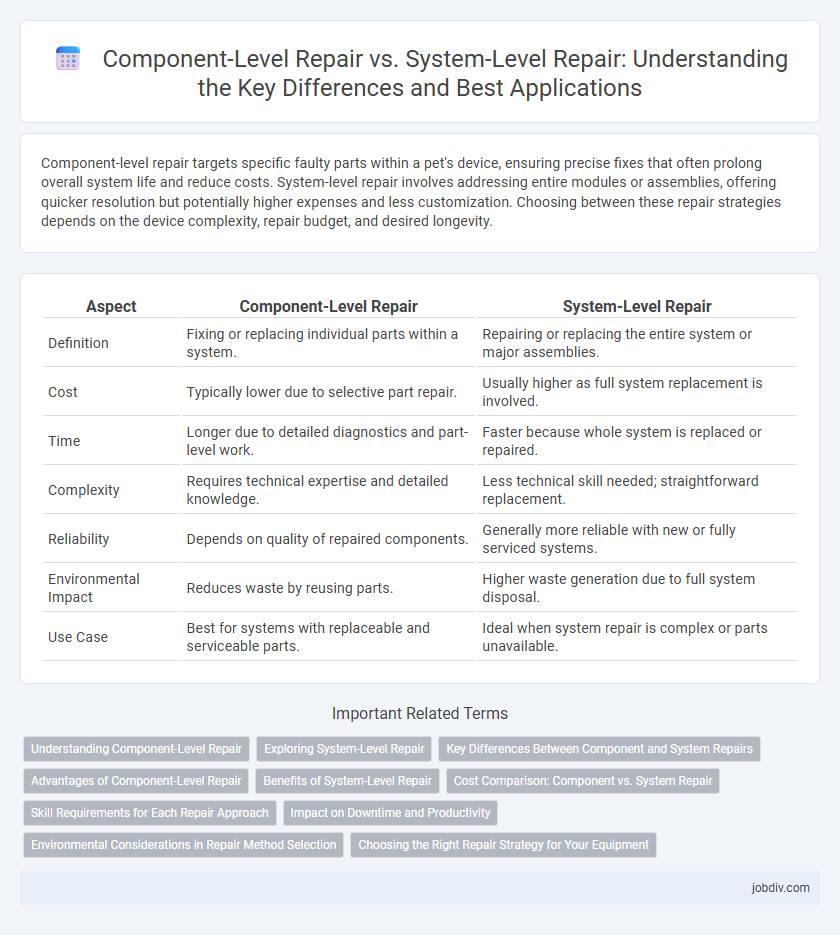

Component-level repair targets specific faulty parts within a pet's device, ensuring precise fixes that often prolong overall system life and reduce costs. System-level repair involves addressing entire modules or assemblies, offering quicker resolution but potentially higher expenses and less customization. Choosing between these repair strategies depends on the device complexity, repair budget, and desired longevity.

Table of Comparison

| Aspect | Component-Level Repair | System-Level Repair |

|---|---|---|

| Definition | Fixing or replacing individual parts within a system. | Repairing or replacing the entire system or major assemblies. |

| Cost | Typically lower due to selective part repair. | Usually higher as full system replacement is involved. |

| Time | Longer due to detailed diagnostics and part-level work. | Faster because whole system is replaced or repaired. |

| Complexity | Requires technical expertise and detailed knowledge. | Less technical skill needed; straightforward replacement. |

| Reliability | Depends on quality of repaired components. | Generally more reliable with new or fully serviced systems. |

| Environmental Impact | Reduces waste by reusing parts. | Higher waste generation due to full system disposal. |

| Use Case | Best for systems with replaceable and serviceable parts. | Ideal when system repair is complex or parts unavailable. |

Understanding Component-Level Repair

Component-level repair targets individual parts within a system, allowing for precise fault isolation and cost-effective maintenance without replacing the entire unit. This approach enhances equipment longevity by addressing specific malfunctions and reduces downtime compared to system-level repair. Understanding component-level repair is crucial for technicians aiming to optimize repair strategies and improve operational efficiency.

Exploring System-Level Repair

System-level repair addresses malfunctions by diagnosing and fixing issues within entire assemblies or devices, offering faster restoration compared to component-level repair. This approach reduces downtime and improves reliability by replacing or refurbishing standardized modules rather than individual parts. System-level repair is particularly effective for complex electronics, automotive systems, and industrial machinery, where integration and compatibility are critical.

Key Differences Between Component and System Repairs

Component-level repair targets specific faulty parts within a device, enabling precise fixes that reduce downtime and costs by avoiding full system replacements. System-level repair involves diagnosing and addressing issues at the complete device or assembly level, which can simplify troubleshooting but may lead to higher expenses and longer repair times. Understanding these key differences helps in selecting the most efficient repair strategy based on complexity, cost, and time constraints.

Advantages of Component-Level Repair

Component-level repair offers precise fault isolation, reducing the need to replace entire systems and thus lowering overall maintenance costs. It enhances equipment uptime by enabling faster repairs with targeted part replacements rather than full system overhauls. This approach also supports sustainability by minimizing electronic waste and conserving resources through extended component lifecycles.

Benefits of System-Level Repair

System-level repair reduces downtime by addressing multiple component issues in a single intervention, increasing operational efficiency. It simplifies maintenance logistics by minimizing the need for specialized tools and expertise specific to individual components. This holistic approach often extends the lifespan of the entire system, optimizing overall performance and cost-effectiveness.

Cost Comparison: Component vs. System Repair

Component-level repair typically offers significant cost savings compared to system-level repair by targeting only the faulty parts instead of replacing the entire system. Repairing individual components reduces labor time and minimizes material waste, leading to lower overall expenses and faster turnaround. System-level repairs often involve higher costs due to complete system diagnostics, replacement parts, and potential downtime impacting productivity.

Skill Requirements for Each Repair Approach

Component-level repair demands highly specialized technical skills, including proficiency in diagnostic tools, soldering, and circuit analysis to identify and fix specific faulty parts. System-level repair requires broader knowledge of system architecture and functionality, enabling technicians to troubleshoot and replace entire modules without dissecting individual components. Mastery of component-level repair often leads to cost-effective outcomes, while system-level repair emphasizes speed and reliability in restoring overall system performance.

Impact on Downtime and Productivity

Component-level repair significantly reduces downtime by targeting and fixing specific faulty parts without disrupting the entire system, thereby enhancing productivity with quicker turnaround times. System-level repair often requires complete equipment shutdown and longer repair cycles, leading to extended downtime and loss of operational efficiency. Organizations focusing on minimizing downtime prioritize component-level repair strategies to maintain continuous workflow and maximize asset utilization.

Environmental Considerations in Repair Method Selection

Component-level repair significantly reduces electronic waste by targeting and fixing individual parts instead of discarding entire systems, promoting sustainable resource use. System-level repair often leads to higher energy consumption and material waste due to replacing whole units, which negatively impacts environmental footprints. Prioritizing component-level repair aligns with eco-friendly practices and regulatory standards aimed at minimizing environmental degradation in repair processes.

Choosing the Right Repair Strategy for Your Equipment

Selecting the appropriate repair strategy depends on factors such as equipment complexity, downtime tolerance, and cost considerations. Component-level repair targets specific faulty parts, maximizing cost-efficiency and reducing waste, while system-level repair involves replacing or refurbishing entire assemblies for faster turnaround and reliability. Evaluating failure frequency, diagnostic capabilities, and operational impact ensures an optimal balance between maintenance expenses and equipment performance.

Component-Level Repair vs System-Level Repair Infographic

jobdiv.com

jobdiv.com