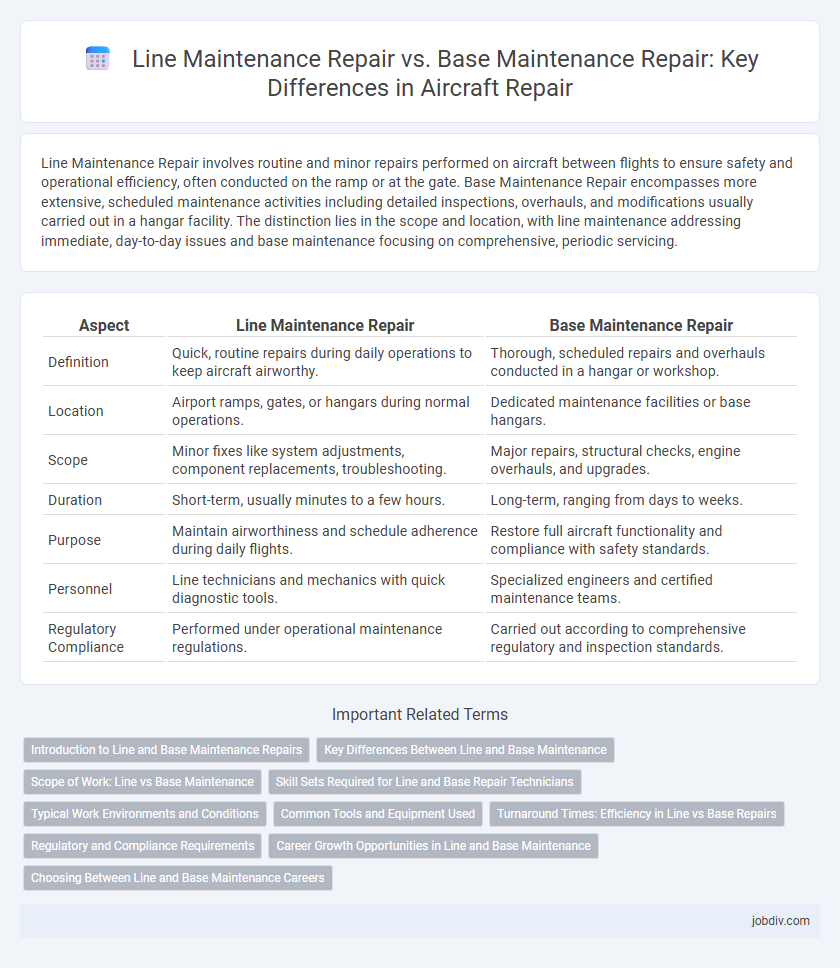

Line Maintenance Repair involves routine and minor repairs performed on aircraft between flights to ensure safety and operational efficiency, often conducted on the ramp or at the gate. Base Maintenance Repair encompasses more extensive, scheduled maintenance activities including detailed inspections, overhauls, and modifications usually carried out in a hangar facility. The distinction lies in the scope and location, with line maintenance addressing immediate, day-to-day issues and base maintenance focusing on comprehensive, periodic servicing.

Table of Comparison

| Aspect | Line Maintenance Repair | Base Maintenance Repair |

|---|---|---|

| Definition | Quick, routine repairs during daily operations to keep aircraft airworthy. | Thorough, scheduled repairs and overhauls conducted in a hangar or workshop. |

| Location | Airport ramps, gates, or hangars during normal operations. | Dedicated maintenance facilities or base hangars. |

| Scope | Minor fixes like system adjustments, component replacements, troubleshooting. | Major repairs, structural checks, engine overhauls, and upgrades. |

| Duration | Short-term, usually minutes to a few hours. | Long-term, ranging from days to weeks. |

| Purpose | Maintain airworthiness and schedule adherence during daily flights. | Restore full aircraft functionality and compliance with safety standards. |

| Personnel | Line technicians and mechanics with quick diagnostic tools. | Specialized engineers and certified maintenance teams. |

| Regulatory Compliance | Performed under operational maintenance regulations. | Carried out according to comprehensive regulatory and inspection standards. |

Introduction to Line and Base Maintenance Repairs

Line Maintenance Repair involves routine inspections and minor repairs conducted at an airport gate or hangar to ensure aircraft safety and operational readiness between flights. Base Maintenance Repair encompasses more intensive, scheduled overhauls, structural repairs, and system upgrades performed in specialized facilities with extensive tools and longer downtime. Understanding the distinction between line and base maintenance repairs is crucial for optimizing aircraft availability and maintenance efficiency.

Key Differences Between Line and Base Maintenance

Line maintenance repair involves routine checks and minor repairs performed on aircraft between flights to ensure immediate airworthiness, focusing on tasks such as fluid replenishment, system inspections, and troubleshooting. Base maintenance repair encompasses extensive overhauls, structural repairs, and detailed inspections conducted in hangars, often requiring the aircraft to be grounded for an extended period. The key differences lie in the scope, complexity, and location of the work: line maintenance provides quick, on-site interventions to keep aircraft operational, while base maintenance delivers comprehensive, scheduled repairs to maintain long-term safety and compliance.

Scope of Work: Line vs Base Maintenance

Line maintenance repair encompasses routine tasks such as daily inspections, minor repairs, and troubleshooting performed on aircraft between flights to ensure immediate airworthiness. Base maintenance repair involves comprehensive checks, heavy repairs, structural modifications, and overhauls conducted at specialized facilities, typically requiring longer aircraft downtime. The scope of line maintenance focuses on rapid turnaround and operational readiness, while base maintenance targets in-depth assessments and major corrective actions.

Skill Sets Required for Line and Base Repair Technicians

Line maintenance repair technicians require skills in quick troubleshooting, routine inspections, and minor repairs to ensure aircraft readiness between flights, emphasizing diagnostic proficiency and time management. Base maintenance repair technicians need advanced expertise in structural repairs, system overhauls, and compliance with detailed regulatory standards, demanding in-depth technical knowledge and precision. The skill sets diverge significantly, with line technicians focusing on rapid issue resolution and base technicians specializing in comprehensive, long-term maintenance tasks.

Typical Work Environments and Conditions

Line Maintenance Repair typically occurs at airport ramps, hangars, or gates, addressing routine checks, minor repairs, and troubleshooting under tight time constraints to ensure quick aircraft turnaround. Base Maintenance Repair is performed in specialized hangars equipped with extensive tools and facilities, allowing for comprehensive inspections, overhauls, and complex component replacements under controlled environmental conditions. Both environments demand adherence to strict safety regulations, but base maintenance often involves longer downtimes and more detailed documentation processes.

Common Tools and Equipment Used

Line Maintenance Repair and Base Maintenance Repair utilize essential tools such as torque wrenches, multifunctional screwdrivers, and diagnostic testers to ensure precision and efficiency. Line Maintenance equipment typically includes portable toolkits, safety cones, and ground power units designed for on-the-spot repairs and quick turnarounds. Base Maintenance involves more advanced machinery like hydraulic lifts, engine stands, and comprehensive test benches to support extensive inspections and component replacements.

Turnaround Times: Efficiency in Line vs Base Repairs

Line Maintenance Repair typically features shorter turnaround times due to its focus on routine inspections, minor repairs, and quick fixes performed at the gate or hangar during scheduled stops. Base Maintenance Repair involves more extensive and complex tasks such as structural modifications, overhauls, and heavy repairs requiring longer downtime and specialized facilities. Efficient management of turnaround times is crucial in line maintenance to minimize aircraft ground time and maintain flight schedules, whereas base maintenance prioritizes thoroughness and compliance over speed.

Regulatory and Compliance Requirements

Line Maintenance Repair focuses on routine inspections, minor repairs, and immediate defect rectifications compliant with daily operational safety standards outlined by aviation regulatory bodies like the FAA and EASA. Base Maintenance Repair involves extensive inspections, overhaul, and major modifications requiring adherence to stricter regulatory frameworks, mandatory certifications, and detailed documentation to ensure airworthiness. Both maintenance types mandate strict compliance with prescribed maintenance schedules, approved data, and regulatory audits to maintain aircraft certification and operational safety.

Career Growth Opportunities in Line and Base Maintenance

Line maintenance repair offers technicians rapid skill development through routine inspections and troubleshooting, enabling frequent hands-on experience with aircraft systems under tight schedules. Base maintenance repair provides deeper career growth by involving complex overhauls, structural repairs, and comprehensive system diagnostics, which cultivates expertise in specialized technical fields and quality assurance. Professionals progressing from line to base maintenance roles often achieve higher certifications, leadership positions, and increased responsibility in aircraft maintenance management.

Choosing Between Line and Base Maintenance Careers

Choosing between line maintenance repair and base maintenance repair careers depends on the scope and work environment preferences. Line maintenance involves routine, quick fixes and inspections performed at the airport gate or on the tarmac, requiring strong troubleshooting skills and adaptability. Base maintenance careers focus on comprehensive, scheduled repairs and overhauls within hangars, demanding deep technical knowledge and attention to detail for complex aircraft systems.

Line Maintenance Repair vs Base Maintenance Repair Infographic

jobdiv.com

jobdiv.com