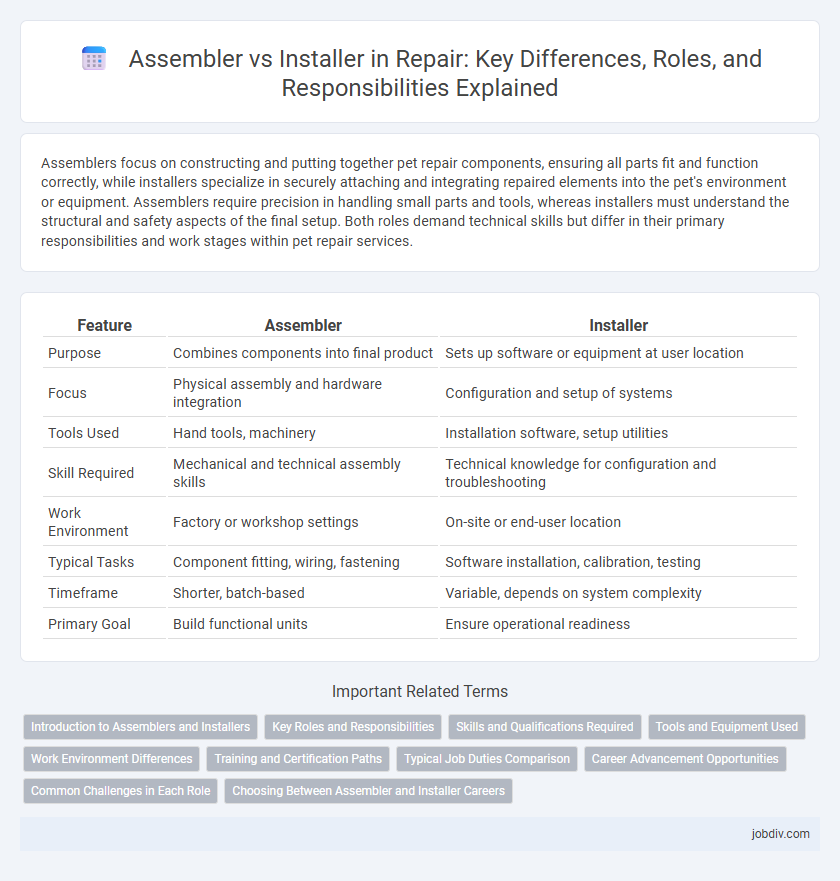

Assemblers focus on constructing and putting together pet repair components, ensuring all parts fit and function correctly, while installers specialize in securely attaching and integrating repaired elements into the pet's environment or equipment. Assemblers require precision in handling small parts and tools, whereas installers must understand the structural and safety aspects of the final setup. Both roles demand technical skills but differ in their primary responsibilities and work stages within pet repair services.

Table of Comparison

| Feature | Assembler | Installer |

|---|---|---|

| Purpose | Combines components into final product | Sets up software or equipment at user location |

| Focus | Physical assembly and hardware integration | Configuration and setup of systems |

| Tools Used | Hand tools, machinery | Installation software, setup utilities |

| Skill Required | Mechanical and technical assembly skills | Technical knowledge for configuration and troubleshooting |

| Work Environment | Factory or workshop settings | On-site or end-user location |

| Typical Tasks | Component fitting, wiring, fastening | Software installation, calibration, testing |

| Timeframe | Shorter, batch-based | Variable, depends on system complexity |

| Primary Goal | Build functional units | Ensure operational readiness |

Introduction to Assemblers and Installers

Assemblers translate assembly language code into machine code, essential for software repair and hardware programming tasks. Installers manage the setup and configuration of software applications, ensuring proper integration and functionality within systems. Efficient repair processes rely on understanding the distinct roles of assemblers for code-level fixes and installers for system-level deployment.

Key Roles and Responsibilities

Assemblers specialize in constructing products by accurately fitting and securing parts according to technical specifications, ensuring structural integrity and quality control. Installers focus on setting up equipment or systems at job sites, performing alignments, calibrations, and functional testing to guarantee operational performance. Both roles demand attention to detail, but assemblers work primarily in controlled environments, while installers adapt to varying field conditions.

Skills and Qualifications Required

Assemblers require strong mechanical skills, the ability to read blueprints, and proficiency in handling hand tools and machinery to accurately construct or repair components. Installers must possess technical knowledge of electrical systems, wiring, and safety protocols, along with skills in interpreting installation manuals to ensure proper setup and functionality. Both roles demand attention to detail, problem-solving abilities, and relevant technical certifications or industry-specific training to meet quality and safety standards.

Tools and Equipment Used

Assemblers typically use precision hand tools such as screwdrivers, pliers, and torque wrenches to fit and secure components accurately, ensuring mechanical integrity in repairs. Installers rely on specialized equipment like drills, impact drivers, and calibration instruments to position and fasten assemblies, often handling larger-scale or specialized installations. Both professions require toolsets tailored to their specific repair tasks, with assemblers focusing on fine adjustments and installers managing robust fastening and alignment tools.

Work Environment Differences

Assemblers typically work in manufacturing plants or assembly lines where the environment is controlled, repetitive, and focused on mass production. Installers often operate on-site at client locations, facing variable conditions such as outdoor settings, confined spaces, or residential areas. The contrast in work environments influences their tools, safety protocols, and physical demands, with assemblers relying on fixed, ergonomic workstations and installers requiring mobility and adaptability to diverse surroundings.

Training and Certification Paths

Assemblers typically follow vocational training programs emphasizing mechanical skills and use on-the-job apprenticeships, while installers often pursue certification courses specific to their industry, such as HVAC or electrical licensing. Certification for assemblers may include CNC machine operation or welding, whereas installers might obtain credentials like OSHA safety training or specialized system installation certificates. Both paths require a combination of technical education and practical experience to ensure proficiency and compliance with industry standards.

Typical Job Duties Comparison

Assemblers typically focus on putting together components and subassemblies according to specifications, using hand tools or machinery to create finished products or parts. Installers specialize in setting up, positioning, and securing equipment or systems at job sites, ensuring proper function and adherence to safety standards. Both roles require reading technical manuals and blueprints, but assemblers work primarily in controlled environments, while installers operate mostly in field locations.

Career Advancement Opportunities

Assemblers typically focus on putting together components in manufacturing settings, which offers foundational skills but limited career advancement without additional training. Installers engage with system setup and troubleshooting, providing broader expertise that can lead to supervisory or technical specialist roles. Pursuing certifications and specialized training in installation significantly enhances career progression prospects within the repair and maintenance industry.

Common Challenges in Each Role

Assemblers often face challenges related to precise component fitting and interpreting complex technical diagrams, which can lead to assembly errors or delays. Installers encounter difficulties in adapting to varying installation environments and troubleshooting unexpected site-specific issues that affect equipment performance. Both roles demand strong problem-solving skills to address mechanical discrepancies and ensure seamless repair outcomes.

Choosing Between Assembler and Installer Careers

Choosing between assembler and installer careers depends on skill specialization and work environment preferences. Assemblers typically focus on building components or products in manufacturing settings, requiring precise mechanical aptitude and attention to detail. Installers work directly with clients to set up equipment or systems on-site, demanding strong problem-solving skills and customer interaction experience.

Assembler vs Installer Infographic

jobdiv.com

jobdiv.com