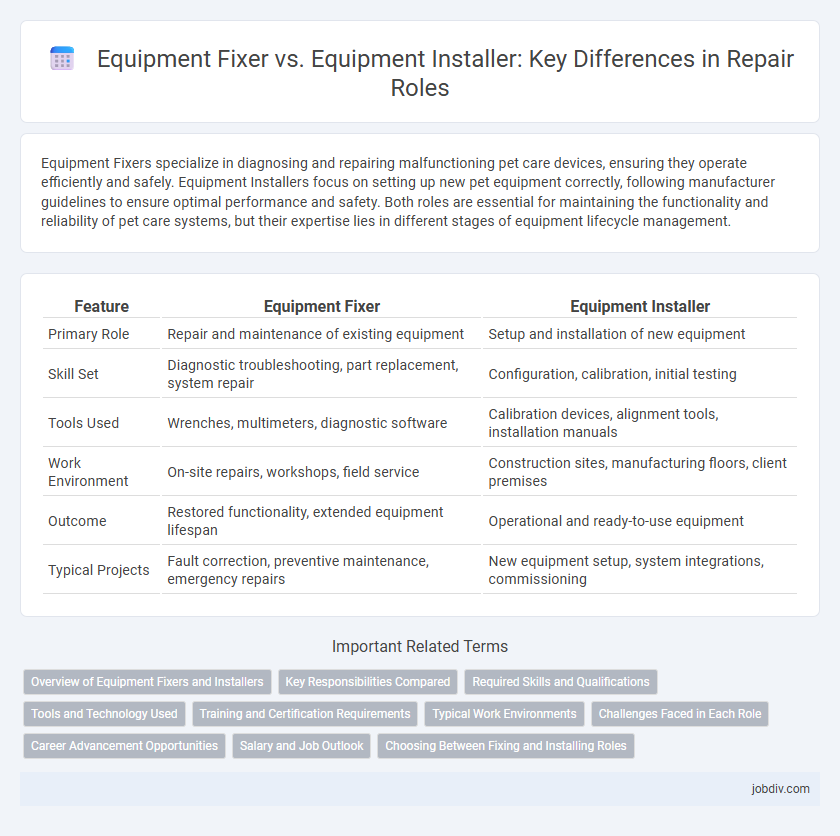

Equipment Fixers specialize in diagnosing and repairing malfunctioning pet care devices, ensuring they operate efficiently and safely. Equipment Installers focus on setting up new pet equipment correctly, following manufacturer guidelines to ensure optimal performance and safety. Both roles are essential for maintaining the functionality and reliability of pet care systems, but their expertise lies in different stages of equipment lifecycle management.

Table of Comparison

| Feature | Equipment Fixer | Equipment Installer |

|---|---|---|

| Primary Role | Repair and maintenance of existing equipment | Setup and installation of new equipment |

| Skill Set | Diagnostic troubleshooting, part replacement, system repair | Configuration, calibration, initial testing |

| Tools Used | Wrenches, multimeters, diagnostic software | Calibration devices, alignment tools, installation manuals |

| Work Environment | On-site repairs, workshops, field service | Construction sites, manufacturing floors, client premises |

| Outcome | Restored functionality, extended equipment lifespan | Operational and ready-to-use equipment |

| Typical Projects | Fault correction, preventive maintenance, emergency repairs | New equipment setup, system integrations, commissioning |

Overview of Equipment Fixers and Installers

Equipment fixers specialize in diagnosing, troubleshooting, and repairing malfunctioning machinery, ensuring optimal performance and minimizing downtime. Equipment installers focus on setting up and calibrating new machinery, adhering to manufacturer specifications and safety standards for proper operation. Both roles require technical expertise, but fixers concentrate on maintenance and repairs while installers prioritize initial setup and configuration.

Key Responsibilities Compared

An Equipment Fixer specializes in diagnosing, troubleshooting, and repairing malfunctioning machinery to restore optimal operation, often requiring in-depth mechanical and electrical expertise. An Equipment Installer focuses on setting up, assembling, and calibrating new equipment according to manufacturer specifications and safety standards. Both roles demand technical knowledge, but fixers prioritize maintenance and repair tasks, while installers emphasize accurate installation and initial system validation.

Required Skills and Qualifications

Equipment fixers require strong diagnostic skills, mechanical aptitude, and knowledge of troubleshooting techniques to repair machinery effectively. Equipment installers need expertise in reading technical blueprints, electrical wiring proficiency, and the ability to assemble complex systems according to manufacturer specifications. Both roles demand physical stamina, attention to detail, and safety certification, but fixers focus on repair and maintenance, while installers prioritize proper setup and calibration.

Tools and Technology Used

Equipment fixers utilize diagnostic tools, multimeters, and portable hand tools to identify and repair mechanical and electrical faults, often employing thermal imaging and software-based diagnostic systems for precision. Equipment installers focus on alignment tools, calibration devices, and specialized mounting hardware to ensure proper setup and integration of new machinery within operational environments. Both professionals rely on updated technology, but fixers emphasize fault detection and resolution, whereas installers prioritize accurate assembly and system functionality.

Training and Certification Requirements

Equipment fixers typically require formal training in mechanical or electrical repair, often obtained through technical schools or apprenticeships, and may need certifications such as the Certified Maintenance & Reliability Technician (CMRT) credential. Equipment installers generally complete specialized training programs that emphasize installation protocols, safety standards, and may hold certifications like the OSHA 10/30-Hour Construction Safety certification or manufacturer-specific installation certificates. Both roles demand ongoing education to stay current with evolving technologies, but fixers focus more on troubleshooting and repairs while installers emphasize setup and compliance with installation guidelines.

Typical Work Environments

Equipment fixers typically work in maintenance shops, factories, or industrial plants where machinery requires regular repairs and upkeep to ensure operational efficiency. Equipment installers are often found on construction sites, manufacturing facilities, or commercial buildings, focusing on setting up new machinery and ensuring proper installation. Both roles may occasionally overlap in warehouses or production floors, but their environments primarily differ based on repair versus initial setup tasks.

Challenges Faced in Each Role

Equipment fixers encounter challenges such as diagnosing complex malfunctions, handling urgent repairs under tight deadlines, and managing wear and tear on diverse machinery. Equipment installers face difficulties in precise alignment, interpreting technical blueprints accurately, and coordinating with multiple teams to ensure proper setup. Both roles demand specialized skills but differ in focus--fixers prioritize troubleshooting, while installers emphasize initial configuration and compliance.

Career Advancement Opportunities

Equipment fixers develop technical troubleshooting skills and gain expertise in maintaining various machinery, which opens pathways to senior technician or maintenance supervisor roles. Equipment installers acquire in-depth knowledge of system setup and integration, positioning them for advancement into project management or technical sales careers. Both roles offer distinct career growth opportunities depending on specialization in repair or installation domains.

Salary and Job Outlook

Equipment fixers earn an average salary of $45,000 annually, reflecting steady demand in maintenance and repair roles across manufacturing and industrial sectors. Equipment installers typically command higher wages, averaging $55,000 per year, due to specialized skills required for assembling and setting up complex machinery. Job outlook forecasts a 5% growth rate for both positions over the next decade, driven by ongoing industrial automation and equipment upgrades.

Choosing Between Fixing and Installing Roles

Choosing between an equipment fixer and an equipment installer depends on the specific needs of the project, as fixers specialize in diagnosing and repairing malfunctions, whereas installers focus on setting up and configuring new machinery. Understanding the scope of work, skill requirements, and long-term maintenance goals is essential when deciding which role to prioritize. Effective resource allocation and minimizing downtime hinge on selecting the appropriate professional for either repairing existing equipment or installing new systems.

Equipment Fixer vs Equipment Installer Infographic

jobdiv.com

jobdiv.com