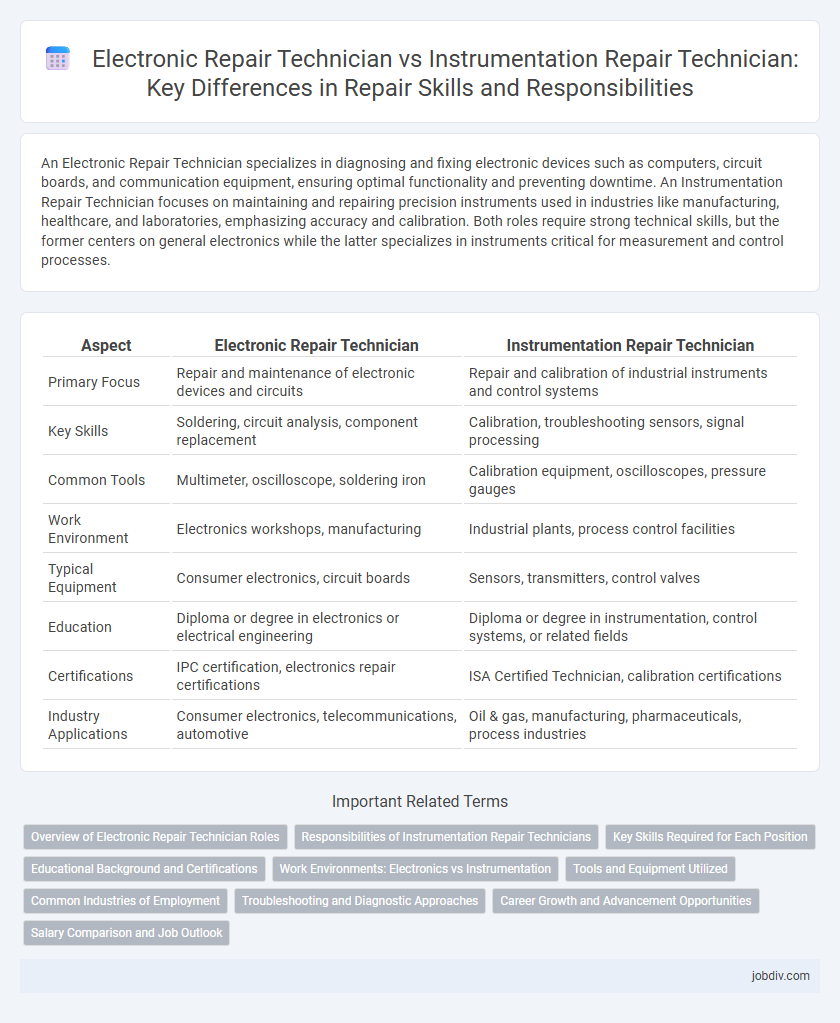

An Electronic Repair Technician specializes in diagnosing and fixing electronic devices such as computers, circuit boards, and communication equipment, ensuring optimal functionality and preventing downtime. An Instrumentation Repair Technician focuses on maintaining and repairing precision instruments used in industries like manufacturing, healthcare, and laboratories, emphasizing accuracy and calibration. Both roles require strong technical skills, but the former centers on general electronics while the latter specializes in instruments critical for measurement and control processes.

Table of Comparison

| Aspect | Electronic Repair Technician | Instrumentation Repair Technician |

|---|---|---|

| Primary Focus | Repair and maintenance of electronic devices and circuits | Repair and calibration of industrial instruments and control systems |

| Key Skills | Soldering, circuit analysis, component replacement | Calibration, troubleshooting sensors, signal processing |

| Common Tools | Multimeter, oscilloscope, soldering iron | Calibration equipment, oscilloscopes, pressure gauges |

| Work Environment | Electronics workshops, manufacturing | Industrial plants, process control facilities |

| Typical Equipment | Consumer electronics, circuit boards | Sensors, transmitters, control valves |

| Education | Diploma or degree in electronics or electrical engineering | Diploma or degree in instrumentation, control systems, or related fields |

| Certifications | IPC certification, electronics repair certifications | ISA Certified Technician, calibration certifications |

| Industry Applications | Consumer electronics, telecommunications, automotive | Oil & gas, manufacturing, pharmaceuticals, process industries |

Overview of Electronic Repair Technician Roles

Electronic Repair Technicians specialize in diagnosing, troubleshooting, and repairing electronic devices such as computers, communication equipment, and consumer electronics, ensuring system functionality and performance. Their expertise includes circuit board analysis, soldering, and software updates to resolve hardware and firmware issues. Skilled in using diagnostic tools and schematics, they maintain and restore equipment to optimal operation in various industries including telecommunications, consumer electronics, and industrial automation.

Responsibilities of Instrumentation Repair Technicians

Instrumentation Repair Technicians specialize in diagnosing, calibrating, and repairing complex analytical instruments and control systems used in manufacturing and industrial processes. Their responsibilities include troubleshooting sensors, transducers, and automated control devices to ensure accurate data collection and optimal system performance. They often collaborate with engineers to maintain regulatory compliance and reduce downtime through preventive maintenance and precise instrument calibration.

Key Skills Required for Each Position

Electronic Repair Technicians require proficiency in circuit analysis, soldering, and troubleshooting electronic components such as resistors, capacitors, and integrated circuits. Instrumentation Repair Technicians must master calibration techniques, control systems diagnostics, and familiarity with sensors and transducers used in automated industrial processes. Both roles demand strong problem-solving abilities, but Electronic Repair Technicians focus more on microelectronics, while Instrumentation Repair Technicians emphasize precision measurement and control technology.

Educational Background and Certifications

Electronic Repair Technicians typically hold an associate degree or diploma in electronics or electrical engineering, with certifications like CompTIA A+ or IPC-A-620 enhancing their qualifications. Instrumentation Repair Technicians often require specialized training in instrumentation technology or industrial automation, supported by certifications such as Certified Control Systems Technician (CCST) or ISA Certified Automation Professional (CAP). Both roles demand strong technical knowledge but differ significantly in their educational focus and certification paths tailored to their specific repair and maintenance tasks.

Work Environments: Electronics vs Instrumentation

Electronic Repair Technicians primarily work in manufacturing plants, service centers, and electronics workshops where they diagnose and fix consumer electronics, circuit boards, and communication devices. Instrumentation Repair Technicians operate in industrial settings such as refineries, power plants, and chemical factories, focusing on maintaining and calibrating complex measuring instruments and control systems. The distinct work environments influence their tools, safety protocols, and daily tasks, with Electronics technicians often handling smaller components and Instrumentation technicians dealing with large-scale, precision instruments.

Tools and Equipment Utilized

Electronic Repair Technicians primarily use multimeters, oscilloscopes, soldering irons, and circuit board testers to diagnose and fix electronic devices, focusing on components like resistors, capacitors, and integrated circuits. Instrumentation Repair Technicians rely on specialized calibration tools, pressure gauges, signal generators, and analyzers to maintain and repair sensors, transducers, and control systems in industrial environments. Both roles require precision tools, but Instrumentation Repair Technicians emphasize equipment that ensures measurement accuracy and system functionality.

Common Industries of Employment

Electronic repair technicians commonly find employment in telecommunications, consumer electronics, and manufacturing industries, where they maintain and troubleshoot circuits, circuit boards, and electronic devices. Instrumentation repair technicians typically work in industries such as oil and gas, chemical processing, and pharmaceuticals, focusing on the calibration, maintenance, and repair of control instruments and automated systems. Both roles are essential in industrial production and infrastructure maintenance, ensuring operational efficiency and safety.

Troubleshooting and Diagnostic Approaches

Electronic Repair Technicians utilize advanced circuit analysis and signal tracing methods to identify faults in complex electronic devices, often employing oscilloscopes and multimeters for precise diagnostics. In contrast, Instrumentation Repair Technicians specialize in troubleshooting sensors, transmitters, and control systems by interpreting process signals and calibration data to ensure accurate instrumentation performance. Both roles require a deep understanding of system electronics, but Instrumentation repair emphasizes process control optimization and regulatory compliance diagnostics.

Career Growth and Advancement Opportunities

Electronic Repair Technicians typically experience rapid career growth by mastering a wide range of consumer and industrial electronic devices, enabling transitions into specialized roles such as embedded systems or telecommunications. Instrumentation Repair Technicians focus on maintaining and calibrating precision measurement instruments, which offers advancement into high-demand sectors like manufacturing automation, process control, and quality assurance engineering. Both career paths offer strong opportunities for advancement, but Instrumentation Repair Technicians often benefit from higher earning potential due to specialized skills required in industries such as petrochemical, pharmaceutical, and aerospace.

Salary Comparison and Job Outlook

Electronic repair technicians earn an average salary ranging from $45,000 to $65,000 annually, while instrumentation repair technicians typically command higher salaries between $55,000 and $75,000 due to specialized skills in calibration and control systems. Job outlook for both roles is positive, with a projected growth rate of 5-7% over the next decade, driven by increasing reliance on automated and electronic systems across industries. Instrumentation repair technicians often find more opportunities in sectors like manufacturing and energy, whereas electronic repair technicians have broader prospects in consumer electronics and telecommunications.

Electronic Repair Technician vs Instrumentation Repair Technician Infographic

jobdiv.com

jobdiv.com