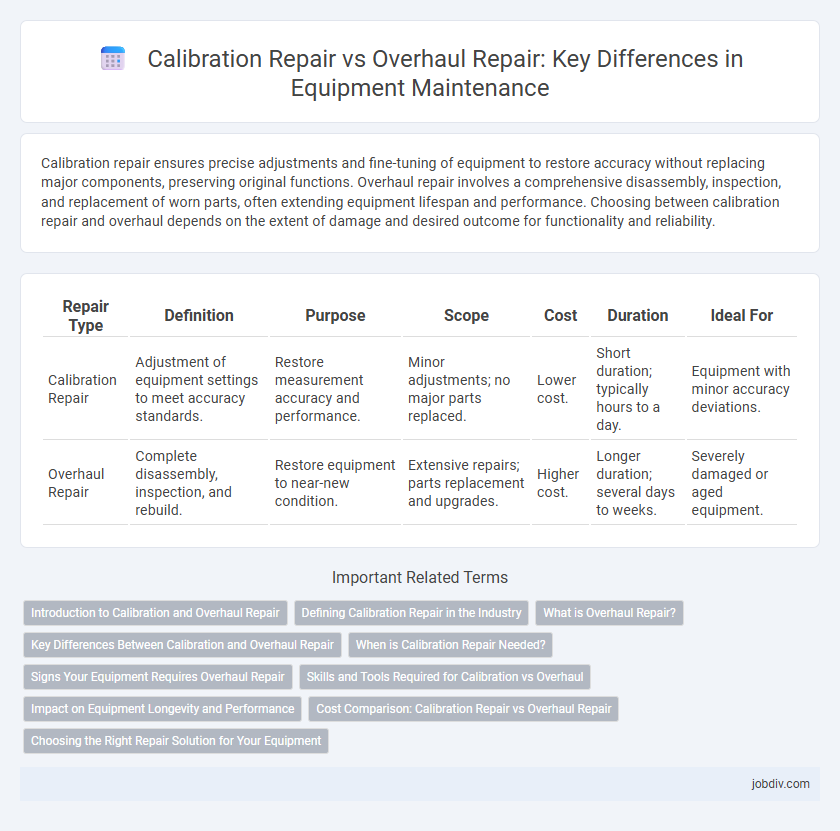

Calibration repair ensures precise adjustments and fine-tuning of equipment to restore accuracy without replacing major components, preserving original functions. Overhaul repair involves a comprehensive disassembly, inspection, and replacement of worn parts, often extending equipment lifespan and performance. Choosing between calibration repair and overhaul depends on the extent of damage and desired outcome for functionality and reliability.

Table of Comparison

| Repair Type | Definition | Purpose | Scope | Cost | Duration | Ideal For |

|---|---|---|---|---|---|---|

| Calibration Repair | Adjustment of equipment settings to meet accuracy standards. | Restore measurement accuracy and performance. | Minor adjustments; no major parts replaced. | Lower cost. | Short duration; typically hours to a day. | Equipment with minor accuracy deviations. |

| Overhaul Repair | Complete disassembly, inspection, and rebuild. | Restore equipment to near-new condition. | Extensive repairs; parts replacement and upgrades. | Higher cost. | Longer duration; several days to weeks. | Severely damaged or aged equipment. |

Introduction to Calibration and Overhaul Repair

Calibration repair ensures precise measurement accuracy by restoring instruments to their original specifications through detailed adjustments and fine-tuning. Overhaul repair involves comprehensive disassembly, inspection, cleaning, and replacement of worn components to extend equipment lifespan and improve overall performance. Both processes are critical in maintaining operational reliability, with calibration focusing on accuracy and overhaul emphasizing structural integrity.

Defining Calibration Repair in the Industry

Calibration repair in the industry involves precise adjustments and fine-tuning of instruments to ensure measurement accuracy within specified tolerances. This process focuses on restoring equipment to its optimal performance without extensive disassembly or part replacement typical of overhaul repair. By maintaining calibration integrity, businesses ensure compliance with quality standards and minimize downtime.

What is Overhaul Repair?

Overhaul repair involves a comprehensive inspection and restoration process that returns equipment or machinery to like-new condition by disassembling, cleaning, replacing worn components, and reassembling. This type of repair extends the service life of assets by addressing all major parts, ensuring reliability and performance meet or exceed original specifications. Overhaul repair is more thorough and costly compared to calibration repair, which primarily focuses on adjusting and fine-tuning instruments for accuracy.

Key Differences Between Calibration and Overhaul Repair

Calibration repair focuses on adjusting and fine-tuning equipment to ensure accuracy and performance meet specified standards, typically involving precise measurement tools and minimal part replacement. Overhaul repair involves comprehensive disassembly, inspection, and restoration or replacement of worn components, aiming to return equipment to like-new condition and extend its operational lifespan. Calibration repair is a targeted process addressing measurement accuracy, while overhaul repair is an extensive refurbishment targeting mechanical wear and system integrity.

When is Calibration Repair Needed?

Calibration repair is needed when measurement instruments or devices produce inaccurate readings, fail to meet specified tolerances, or exhibit drift over time, affecting operational precision and compliance. It becomes essential after regular usage, exposure to harsh environments, or following mechanical shocks to ensure sensor accuracy and proper functionality. Timely calibration repair helps maintain quality control, safety standards, and reduces the risk of costly downtime or defective outputs.

Signs Your Equipment Requires Overhaul Repair

Equipment requiring overhaul repair often exhibits persistent performance issues, such as frequent breakdowns and inconsistent output quality, that calibration repair cannot resolve. Signs include unusual noises, excessive wear, and failure to meet operational specifications despite regular maintenance. Overhaul repair involves comprehensive disassembly, inspection, and replacement of critical components to restore equipment to optimal functionality.

Skills and Tools Required for Calibration vs Overhaul

Calibration repair demands precision instruments such as dial indicators, micrometers, and calibration software, alongside skills in measurement analysis, adjustment techniques, and adherence to standards like ISO/IEC 17025. Overhaul repair requires advanced mechanical tools including torque wrenches, hydraulic presses, and diagnostic equipment, with expertise in disassembly, parts replacement, and system reassembly to restore equipment functionality. Both processes necessitate strong technical knowledge, but calibration emphasizes fine measurement accuracy while overhaul focuses on comprehensive mechanical restoration.

Impact on Equipment Longevity and Performance

Calibration repair precisely restores equipment accuracy by adjusting measurement systems to manufacturer specifications, significantly enhancing performance and extending operational lifespan. Overhaul repair involves comprehensive disassembly, inspection, and replacement of worn components, addressing both visible and latent defects to prevent future failures and maximize durability. Choosing calibration repair optimizes immediate functionality, while overhaul repair ensures long-term reliability and sustained equipment longevity.

Cost Comparison: Calibration Repair vs Overhaul Repair

Calibration repair generally incurs lower costs compared to overhaul repair due to its targeted adjustment of instrument accuracy without extensive disassembly or part replacement. Overhaul repair involves comprehensive inspection, cleaning, and replacement of defective components, leading to higher labor and parts expenses. Choosing calibration repair can significantly reduce downtime and maintenance budgets when the primary issue is measurement deviation rather than mechanical failure.

Choosing the Right Repair Solution for Your Equipment

Calibration repair focuses on restoring equipment accuracy by adjusting measurement settings to meet specified standards, ensuring operational precision without extensive part replacement. Overhaul repair involves comprehensive disassembly, inspection, and replacement of worn or damaged components to restore equipment functionality and extend service life. Selecting the right repair solution depends on the equipment's condition, operational demands, and budget constraints to optimize performance and minimize downtime.

Calibration Repair vs Overhaul Repair Infographic

jobdiv.com

jobdiv.com