Bench repair offers a controlled environment for diagnosing and fixing pet equipment with specialized tools and thorough testing, ensuring precise and reliable results. Field service provides on-site repairs, making it a convenient choice for urgent or bulky equipment that cannot be easily transported. Choosing between bench repair and field service depends on the complexity of the issue, equipment size, and urgency of the repair.

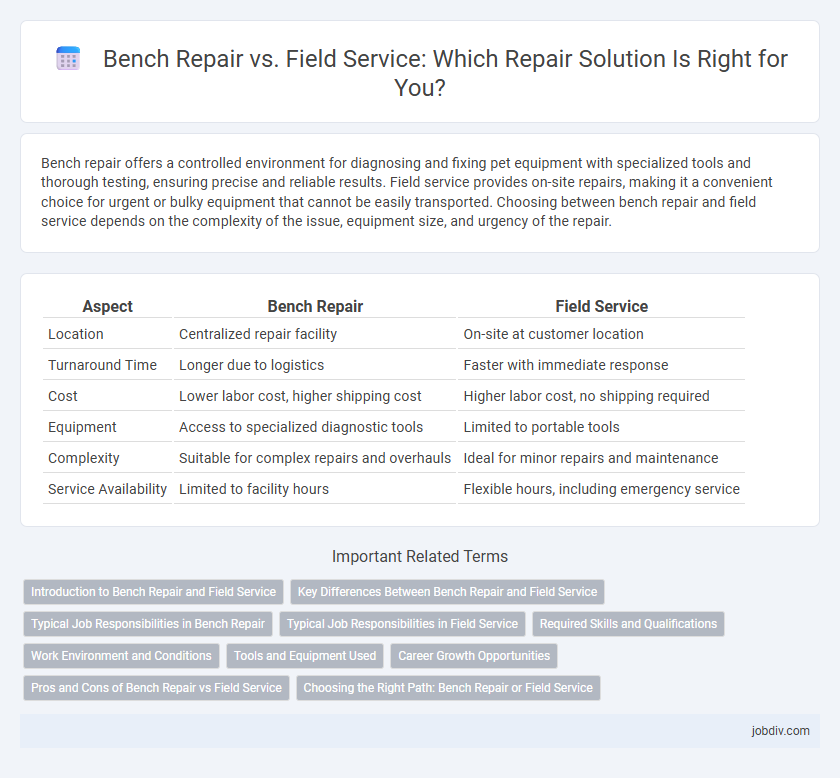

Table of Comparison

| Aspect | Bench Repair | Field Service |

|---|---|---|

| Location | Centralized repair facility | On-site at customer location |

| Turnaround Time | Longer due to logistics | Faster with immediate response |

| Cost | Lower labor cost, higher shipping cost | Higher labor cost, no shipping required |

| Equipment | Access to specialized diagnostic tools | Limited to portable tools |

| Complexity | Suitable for complex repairs and overhauls | Ideal for minor repairs and maintenance |

| Service Availability | Limited to facility hours | Flexible hours, including emergency service |

Introduction to Bench Repair and Field Service

Bench repair involves servicing equipment in a dedicated workshop where technicians have access to specialized tools and controlled environments for precise diagnostics and repairs. Field service refers to onsite maintenance and troubleshooting performed at the customer's location, offering immediate support and minimizing downtime. Choosing between bench repair and field service depends on factors such as equipment complexity, urgency, and logistics.

Key Differences Between Bench Repair and Field Service

Bench repair involves sending equipment to a specialized facility where technicians perform detailed diagnostics and extensive repairs using advanced tools and controlled environments. Field service, by contrast, is conducted on-site at the customer's location, allowing for immediate troubleshooting and repairs that minimize downtime but may be limited by available tools and conditions. The key differences lie in the repair setting, the complexity of tasks performed, and the impact on operational continuity.

Typical Job Responsibilities in Bench Repair

Bench repair technicians specialize in diagnosing, disassembling, and restoring electronic or mechanical devices within a controlled workshop environment. They perform detailed inspections, replace faulty components, conduct functionality tests, and ensure equipment meets manufacturer specifications before returning it to service. This role requires precision, expertise in soldering, calibration, and adherence to safety and quality standards.

Typical Job Responsibilities in Field Service

Field Service technicians perform on-site diagnostics, maintenance, and repairs of equipment to minimize downtime and ensure operational continuity. They interact directly with customers, providing training, support, and preventive maintenance tailored to specific environments. Travel logistics, troubleshooting diverse systems, and adapting to variable working conditions define their typical daily responsibilities.

Required Skills and Qualifications

Bench repair technicians require advanced technical skills in diagnostics, component-level soldering, and in-depth knowledge of electronic schematics, often necessitating certifications like IPC or manufacturer-specific credentials. Field service technicians need strong troubleshooting abilities, adaptability to diverse environments, and excellent customer communication skills, supported by experience with on-site equipment repairs and real-time problem resolution. Both roles demand a solid foundation in electrical engineering principles and proficiency with specialized diagnostic tools to ensure accurate, efficient repairs.

Work Environment and Conditions

Bench repair offers a controlled work environment with stable temperature, lighting, and access to specialized tools, ensuring precise diagnostics and repairs on electronic and mechanical components. Field service operates in variable and often challenging conditions, such as outdoor sites or client facilities, requiring technicians to adapt quickly to diverse environments and limited resources. Understanding these differences is crucial for optimizing repair efficiency, equipment safety, and technician effectiveness in each setting.

Tools and Equipment Used

Bench repair typically utilizes specialized diagnostic tools, precision instruments, and stationary equipment such as oscilloscopes, multimeters, and soldering stations to ensure accurate and thorough servicing. Field service technicians rely on portable diagnostic devices, battery-powered tools, and compact toolkits designed for on-site repairs, emphasizing mobility and quick troubleshooting. The choice of tools reflects the repair environment, where bench repair prioritizes high-precision equipment, while field service demands versatility and portability.

Career Growth Opportunities

Bench repair offers technicians in-depth exposure to complex diagnostics and hands-on experience with advanced electronic components, enhancing technical expertise essential for specialized career advancement. Field service roles develop versatile problem-solving skills and customer interaction capabilities, broadening professional scope and opening pathways to roles in technical sales, training, or management. Balancing both bench repair and field service experience can significantly improve career growth prospects in the repair industry by combining technical proficiency with real-world operational insights.

Pros and Cons of Bench Repair vs Field Service

Bench repair offers precise diagnostics and controlled environment repairs, ensuring higher-quality outcomes for complex devices, but it often involves longer turnaround times and transportation costs. Field service provides faster response and on-site convenience, reducing equipment downtime and eliminating transportation risks, yet it may lack comprehensive testing capabilities available in bench repair. Selecting between bench repair and field service depends on factors like urgency, device complexity, cost constraints, and the need for thorough diagnostics.

Choosing the Right Path: Bench Repair or Field Service

Choosing between bench repair and field service hinges on the complexity and urgency of the equipment issue. Bench repair offers comprehensive diagnostics and precise parts replacement in a controlled environment, ideal for intricate or delicate devices. Field service provides rapid on-site fixes minimizing downtime, suitable for urgent repairs or when equipment immobility is a factor.

Bench Repair vs Field Service Infographic

jobdiv.com

jobdiv.com