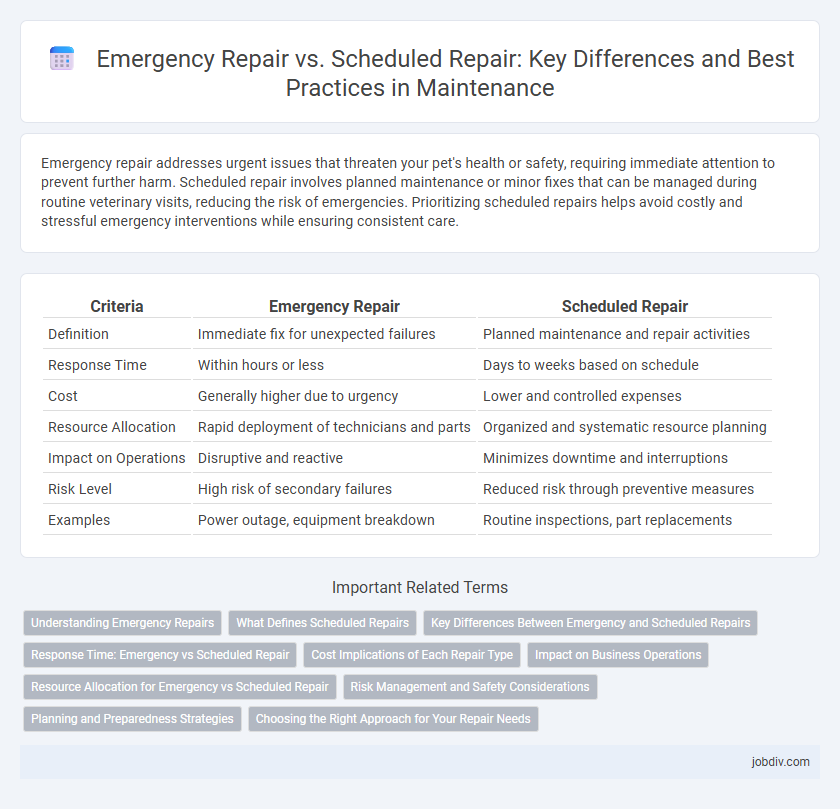

Emergency repair addresses urgent issues that threaten your pet's health or safety, requiring immediate attention to prevent further harm. Scheduled repair involves planned maintenance or minor fixes that can be managed during routine veterinary visits, reducing the risk of emergencies. Prioritizing scheduled repairs helps avoid costly and stressful emergency interventions while ensuring consistent care.

Table of Comparison

| Criteria | Emergency Repair | Scheduled Repair |

|---|---|---|

| Definition | Immediate fix for unexpected failures | Planned maintenance and repair activities |

| Response Time | Within hours or less | Days to weeks based on schedule |

| Cost | Generally higher due to urgency | Lower and controlled expenses |

| Resource Allocation | Rapid deployment of technicians and parts | Organized and systematic resource planning |

| Impact on Operations | Disruptive and reactive | Minimizes downtime and interruptions |

| Risk Level | High risk of secondary failures | Reduced risk through preventive measures |

| Examples | Power outage, equipment breakdown | Routine inspections, part replacements |

Understanding Emergency Repairs

Emergency repairs address unexpected breakdowns or failures, requiring immediate action to prevent further damage or safety hazards. These repairs prioritize rapid response and resource allocation, often bypassing usual scheduling to restore function as quickly as possible. Understanding emergency repairs involves recognizing critical issues such as power outages, leaks, or structural damages that demand urgent intervention.

What Defines Scheduled Repairs

Scheduled repairs are planned maintenance activities performed at predetermined intervals to prevent unexpected equipment failures and extend asset lifespan. These repairs are guided by manufacturer recommendations, historical data, and routine inspections to identify wear and potential issues before malfunction occurs. Scheduled repairs optimize operational efficiency by minimizing downtime and reducing emergency repair costs.

Key Differences Between Emergency and Scheduled Repairs

Emergency repairs address unexpected equipment failures requiring immediate action to minimize downtime and prevent safety hazards. Scheduled repairs are planned maintenance activities conducted during non-peak hours to ensure optimal performance and extend asset lifespan. Prioritizing emergency repairs reduces operational disruptions, while scheduled repairs enable cost-effective resource allocation and improved system reliability.

Response Time: Emergency vs Scheduled Repair

Emergency repairs demand immediate response times, often within minutes to hours, to prevent further damage and ensure safety. Scheduled repairs allow for longer planning windows, typically ranging from days to weeks, prioritizing efficiency and resource allocation. The stark difference in response time heavily influences cost, urgency, and operational disruption between these repair types.

Cost Implications of Each Repair Type

Emergency repairs often incur higher costs due to urgent labor rates, expedited parts shipping, and potential overtime charges. Scheduled repairs allow for budget planning with lower expenses, as parts can be sourced in advance and labor can be scheduled during regular hours. Businesses save significantly by minimizing emergency repairs through proactive maintenance and timely scheduling.

Impact on Business Operations

Emergency repair disrupts business operations by causing unplanned downtime and urgent resource reallocation, often leading to increased costs and reduced productivity. Scheduled repair allows for maintenance during low-impact periods, minimizing operational disruptions and supporting consistent workflow. Strategic planning of repairs enhances asset reliability and reduces the risk of unexpected failures that can halt business processes.

Resource Allocation for Emergency vs Scheduled Repair

Emergency repair demands immediate resource allocation, often requiring on-call technicians, specialized tools, and rapid procurement of parts to minimize downtime and prevent further damage. Scheduled repair allows for strategic planning of workforce, inventory, and equipment, optimizing resource use by aligning tasks with normal operating hours and supplier availability. Balancing resource allocation between emergency and scheduled repairs enhances operational efficiency and reduces overall maintenance costs.

Risk Management and Safety Considerations

Emergency repair addresses critical failures requiring immediate action to prevent hazards, often involving higher risks due to time constraints and limited preparation. Scheduled repair allows for comprehensive risk assessments, proper resource allocation, and safety protocols, minimizing workplace accidents and equipment damage. Prioritizing scheduled maintenance reduces emergency interventions, enhancing overall operational safety and risk management effectiveness.

Planning and Preparedness Strategies

Effective planning and preparedness strategies differentiate emergency repair from scheduled repair by emphasizing readiness versus routine maintenance. Scheduled repairs are strategically planned to minimize downtime, utilizing maintenance schedules, predictive analytics, and resource allocation to anticipate failures. Emergency repairs demand rapid response protocols, contingency planning, and immediate mobilization of skilled personnel to address unexpected breakdowns and mitigate operational disruptions.

Choosing the Right Approach for Your Repair Needs

Emergency repair addresses critical issues immediately to prevent further damage and minimize downtime, making it essential for urgent mechanical failures or safety hazards. Scheduled repair allows for planned maintenance, reducing unexpected breakdowns and optimizing equipment lifespan through regular inspections and timely part replacements. Selecting the right approach depends on the severity of the problem, availability of resources, and the impact on operational efficiency.

Emergency Repair vs Scheduled Repair Infographic

jobdiv.com

jobdiv.com