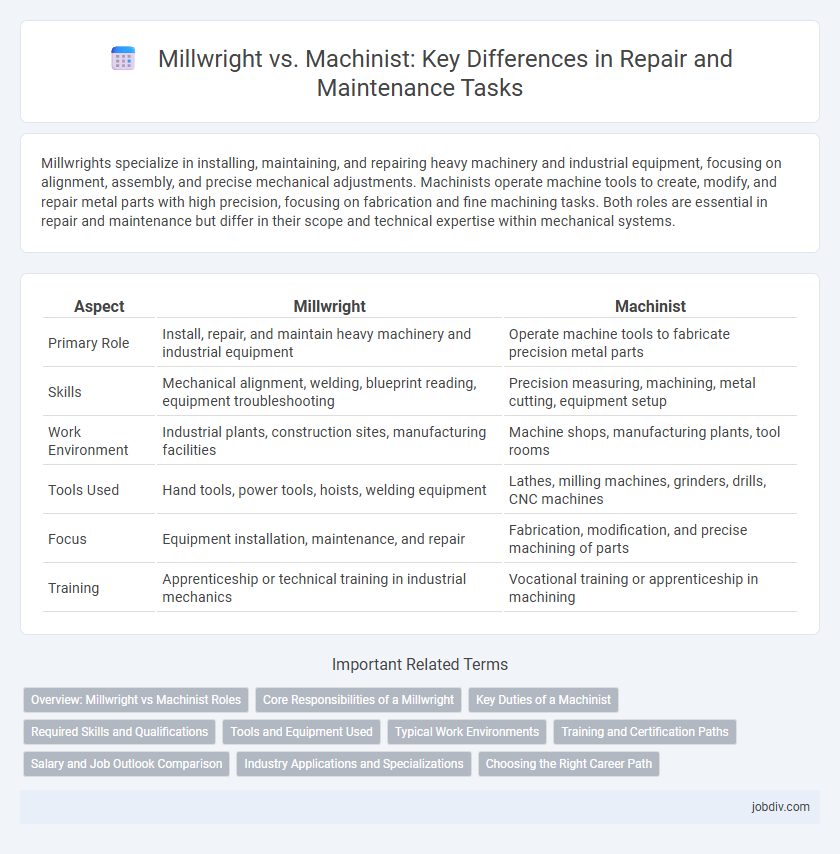

Millwrights specialize in installing, maintaining, and repairing heavy machinery and industrial equipment, focusing on alignment, assembly, and precise mechanical adjustments. Machinists operate machine tools to create, modify, and repair metal parts with high precision, focusing on fabrication and fine machining tasks. Both roles are essential in repair and maintenance but differ in their scope and technical expertise within mechanical systems.

Table of Comparison

| Aspect | Millwright | Machinist |

|---|---|---|

| Primary Role | Install, repair, and maintain heavy machinery and industrial equipment | Operate machine tools to fabricate precision metal parts |

| Skills | Mechanical alignment, welding, blueprint reading, equipment troubleshooting | Precision measuring, machining, metal cutting, equipment setup |

| Work Environment | Industrial plants, construction sites, manufacturing facilities | Machine shops, manufacturing plants, tool rooms |

| Tools Used | Hand tools, power tools, hoists, welding equipment | Lathes, milling machines, grinders, drills, CNC machines |

| Focus | Equipment installation, maintenance, and repair | Fabrication, modification, and precise machining of parts |

| Training | Apprenticeship or technical training in industrial mechanics | Vocational training or apprenticeship in machining |

Overview: Millwright vs Machinist Roles

Millwrights specialize in installing, maintaining, and repairing heavy machinery and industrial equipment, ensuring precise alignment and mechanical functionality. Machinists focus primarily on operating and maintaining machine tools to fabricate, modify, and repair metal parts with high precision. Both roles require technical skills and knowledge of mechanical systems, but millwrights emphasize equipment installation and structural work, while machinists concentrate on machining components.

Core Responsibilities of a Millwright

Millwrights specialize in installing, aligning, and maintaining heavy machinery and industrial equipment to ensure optimal performance and safety. They read blueprints, use precision measuring instruments, and perform equipment assembly, adjustment, and repair tasks. Expertise in welding, rigging, and equipment troubleshooting distinguishes Millwrights in industrial repair and maintenance roles.

Key Duties of a Machinist

A machinist operates and maintains precision machine tools to manufacture, modify, or repair mechanical parts, following blueprints and technical drawings with exacting detail. Key duties include setting up and adjusting machines such as lathes, milling machines, and grinders, performing precise measurements using calipers and micrometers, and ensuring parts meet detailed specifications for quality and functionality. Machinists also troubleshoot machine malfunctions, conduct routine maintenance, and collaborate with engineers to optimize production processes and improve component accuracy.

Required Skills and Qualifications

Millwrights require expertise in mechanical systems, welding, and heavy equipment installation, often holding certifications in forklift operation and rigging. Machinists specialize in precision metalworking, requiring proficiency in CNC programming, blueprint reading, and quality control, typically validated by apprenticeships or technical diplomas. Both professions demand strong problem-solving abilities, mechanical aptitude, and adherence to safety standards in repair and maintenance contexts.

Tools and Equipment Used

Millwrights primarily use precision measuring instruments such as calibrators, micrometers, and laser alignment tools to install and repair heavy machinery, ensuring exact alignment and functionality. Machinists rely heavily on machine tools like lathes, milling machines, and grinders to fabricate and modify metal parts with high accuracy. Both trades utilize specialized hand tools, but millwrights focus on equipment for assembly and alignment, while machinists emphasize tools for cutting and shaping materials.

Typical Work Environments

Millwrights typically work in industrial settings such as manufacturing plants, power stations, and construction sites, where they install, maintain, and repair heavy machinery and equipment. Machinists are primarily found in machine shops, manufacturing facilities, and aerospace or automotive industries, operating precision tools to create or modify metal parts. Both roles demand hands-on technical skills but differ in workspace dynamics and equipment interaction.

Training and Certification Paths

Millwrights undergo extensive training in mechanical systems, hydraulics, and precision alignment, often completing apprenticeships lasting 3-4 years that combine hands-on experience with classroom instruction. Machinists typically follow a training path centered on operating lathes, mills, and CNC machines, earning certifications such as NIMS (National Institute for Metalworking Skills) to validate their skills. Both professions require specialized certifications to advance, with millwrights focusing on rigging and machinery installation while machinists emphasize precision machining and measurement techniques.

Salary and Job Outlook Comparison

Millwrights earn an average salary ranging from $50,000 to $75,000 annually, while machinists typically make between $40,000 and $60,000 per year. Job outlook for millwrights is expected to grow by 8% over the next decade, reflecting steady demand for industrial machinery maintenance and repair. Machinists face a slightly slower growth rate of about 5%, driven by manufacturing automation and precision part production needs.

Industry Applications and Specializations

Millwrights specialize in the installation, maintenance, and repair of heavy industrial machinery used in manufacturing plants, power generation, and processing facilities. Machinists focus on crafting precision parts and tools through metalworking techniques, essential in aerospace, automotive, and custom fabrication industries. Both roles require expertise in mechanical systems, but millwrights emphasize equipment alignment and assembly, while machinists prioritize precision machining and part fabrication.

Choosing the Right Career Path

Millwrights specialize in installing, maintaining, and repairing heavy machinery in industrial settings, emphasizing mechanical alignment and construction skills. Machinists primarily focus on operating machine tools to create precision metal parts, requiring expertise in metalworking and manufacturing processes. Choosing the right career depends on whether you prefer hands-on assembly and troubleshooting of large equipment (Millwright) or precision machining and fabrication of components (Machinist).

Millwright vs Machinist Infographic

jobdiv.com

jobdiv.com