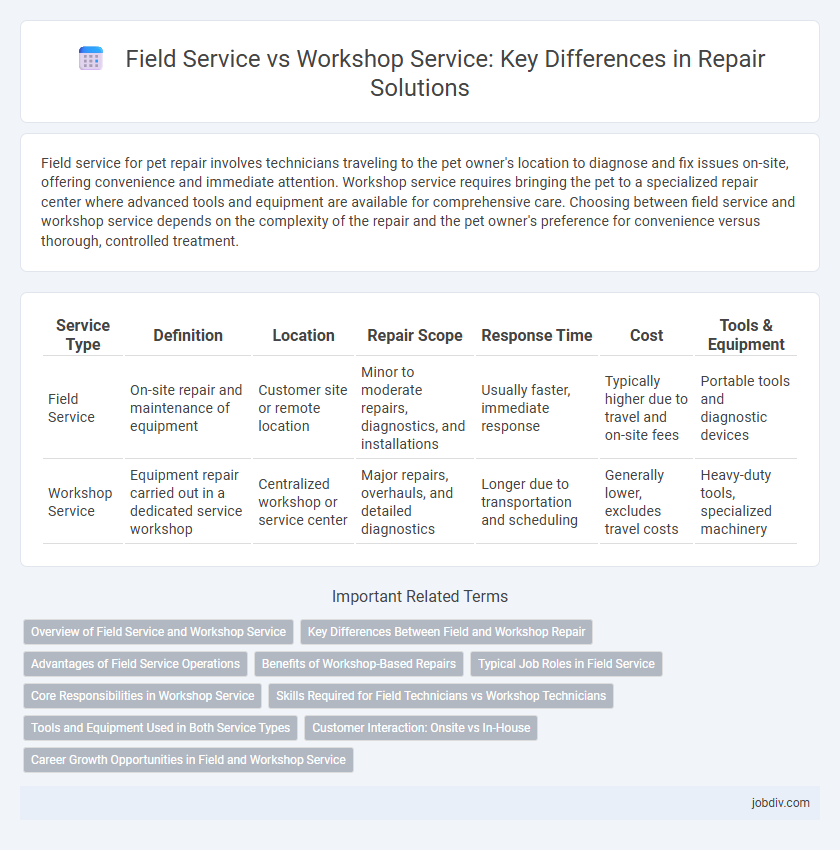

Field service for pet repair involves technicians traveling to the pet owner's location to diagnose and fix issues on-site, offering convenience and immediate attention. Workshop service requires bringing the pet to a specialized repair center where advanced tools and equipment are available for comprehensive care. Choosing between field service and workshop service depends on the complexity of the repair and the pet owner's preference for convenience versus thorough, controlled treatment.

Table of Comparison

| Service Type | Definition | Location | Repair Scope | Response Time | Cost | Tools & Equipment |

|---|---|---|---|---|---|---|

| Field Service | On-site repair and maintenance of equipment | Customer site or remote location | Minor to moderate repairs, diagnostics, and installations | Usually faster, immediate response | Typically higher due to travel and on-site fees | Portable tools and diagnostic devices |

| Workshop Service | Equipment repair carried out in a dedicated service workshop | Centralized workshop or service center | Major repairs, overhauls, and detailed diagnostics | Longer due to transportation and scheduling | Generally lower, excludes travel costs | Heavy-duty tools, specialized machinery |

Overview of Field Service and Workshop Service

Field Service involves technicians performing repairs and maintenance directly at the customer's location, enhancing convenience and reducing equipment downtime. Workshop Service takes place in a dedicated repair facility equipped with specialized tools and machinery, offering comprehensive diagnostics and complex repairs. Both services are critical for effective equipment maintenance, with Field Service prioritizing immediate response and Workshop Service focusing on in-depth technical work.

Key Differences Between Field and Workshop Repair

Field service repair involves technicians traveling to the customer's location to perform repairs on-site, minimizing equipment downtime and offering immediate troubleshooting. Workshop service repair requires transporting equipment to a dedicated facility equipped with specialized tools and diagnostic equipment for more complex or extensive repairs. The key differences include response time, repair complexity, and resource availability, with field service excelling in quick fixes and workshops providing comprehensive, controlled repair environments.

Advantages of Field Service Operations

Field service operations offer significant advantages including faster response times and increased customer satisfaction by enabling repairs at the customer's location, reducing downtime. Technicians equipped with mobile tools and diagnostic equipment can address issues on-site, enhancing operational efficiency and minimizing transportation costs associated with workshop repairs. This approach supports real-time problem-solving and flexibility, leading to improved service quality and optimized resource allocation.

Benefits of Workshop-Based Repairs

Workshop-based repairs provide access to specialized tools and advanced diagnostic equipment that are often unavailable in field service settings, ensuring higher precision and quality. Technicians in workshops benefit from controlled environments, enabling thorough testing and complex repairs without environmental constraints. Centralized repair facilities also streamline parts inventory management, reducing downtime and improving repair turnaround efficiency.

Typical Job Roles in Field Service

Field service technicians specialize in on-site repairs, installing and maintaining equipment directly at the customer's location, which requires strong diagnostic and problem-solving skills. Typical job roles include field engineers, maintenance technicians, and service coordinators who manage schedules and ensure timely responses to service requests. These professionals often work independently under variable environmental conditions, necessitating adaptability and technical expertise specific to the equipment being serviced.

Core Responsibilities in Workshop Service

Workshop service focuses on in-depth diagnostics, component repairs, and complex assemblies conducted in a controlled environment. Technicians specialize in precise equipment calibration, parts replacement, and comprehensive system testing to ensure optimal machinery performance. Efficient inventory management and adherence to safety protocols are core responsibilities integral to maintaining workshop service quality.

Skills Required for Field Technicians vs Workshop Technicians

Field technicians require strong troubleshooting abilities and adaptability to address diverse on-site issues, often working independently in varying environments. Workshop technicians need specialized skills in equipment calibration, detailed diagnostics, and extensive use of repair tools within a controlled setting. Both roles demand technical expertise, but field service emphasizes problem-solving under unpredictable conditions while workshop service prioritizes precision and access to advanced diagnostic equipment.

Tools and Equipment Used in Both Service Types

Field Service utilizes portable diagnostic tools, handheld scanners, and mobile repair kits designed for on-site troubleshooting and immediate fixes, ensuring flexibility and rapid response. Workshop Service employs advanced, stationary equipment such as hydraulic lifts, calibrated diagnostic machines, and specialized tooling, enabling comprehensive repairs and detailed inspections in a controlled environment. The choice of tools directly impacts repair efficiency, with field service prioritizing mobility and workshop service emphasizing precision and depth of maintenance.

Customer Interaction: Onsite vs In-House

Field service enables direct customer interaction through onsite visits, allowing technicians to assess issues in real-time and provide immediate solutions in the customer's environment. Workshop service involves in-house repairs where customers typically drop off equipment, resulting in less direct interaction but often benefiting from specialized tools and controlled conditions. Onsite field service improves customer satisfaction by offering personalized support, while workshop service focuses on comprehensive diagnostics and repair quality.

Career Growth Opportunities in Field and Workshop Service

Field service offers dynamic career growth through hands-on experience with diverse equipment in real-world environments, fostering advanced troubleshooting and customer interaction skills. Workshop service provides specialized career development by enabling technicians to deepen expertise in complex repairs and benefit from access to advanced diagnostic tools and structured training programs. Both paths present unique opportunities for professional advancement, with field service emphasizing adaptability and client communication, and workshop service focusing on technical mastery and precision repair techniques.

Field Service vs Workshop Service Infographic

jobdiv.com

jobdiv.com