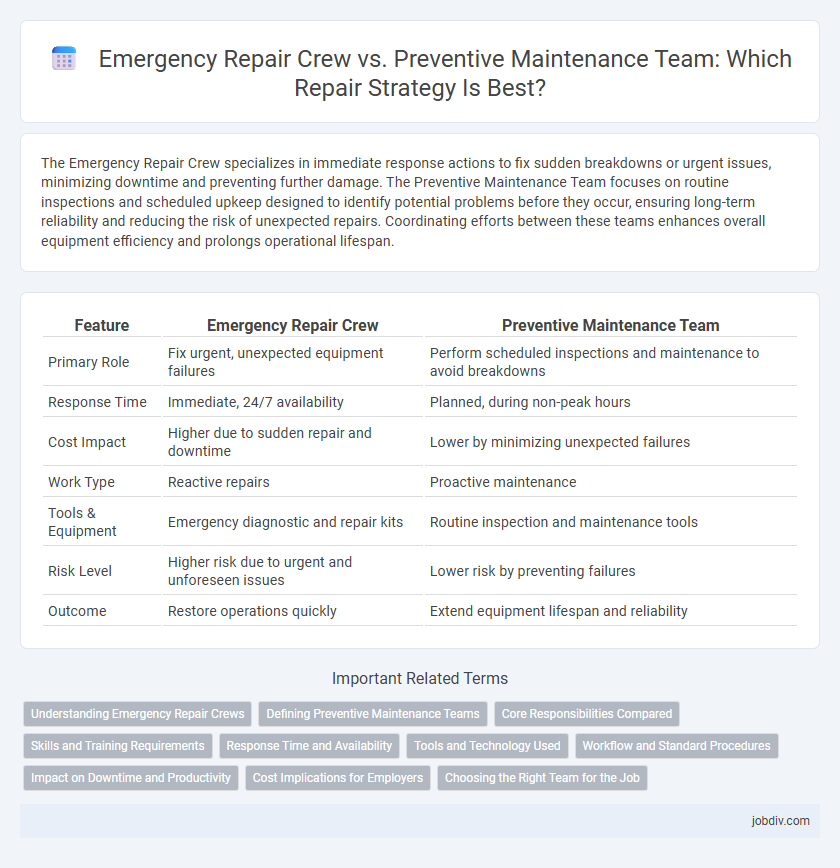

The Emergency Repair Crew specializes in immediate response actions to fix sudden breakdowns or urgent issues, minimizing downtime and preventing further damage. The Preventive Maintenance Team focuses on routine inspections and scheduled upkeep designed to identify potential problems before they occur, ensuring long-term reliability and reducing the risk of unexpected repairs. Coordinating efforts between these teams enhances overall equipment efficiency and prolongs operational lifespan.

Table of Comparison

| Feature | Emergency Repair Crew | Preventive Maintenance Team |

|---|---|---|

| Primary Role | Fix urgent, unexpected equipment failures | Perform scheduled inspections and maintenance to avoid breakdowns |

| Response Time | Immediate, 24/7 availability | Planned, during non-peak hours |

| Cost Impact | Higher due to sudden repair and downtime | Lower by minimizing unexpected failures |

| Work Type | Reactive repairs | Proactive maintenance |

| Tools & Equipment | Emergency diagnostic and repair kits | Routine inspection and maintenance tools |

| Risk Level | Higher risk due to urgent and unforeseen issues | Lower risk by preventing failures |

| Outcome | Restore operations quickly | Extend equipment lifespan and reliability |

Understanding Emergency Repair Crews

Emergency repair crews specialize in responding swiftly to unexpected breakdowns and critical system failures to minimize downtime and operational losses. These teams possess advanced diagnostic tools and expertise to identify root causes rapidly and implement temporary or permanent fixes under high-pressure conditions. Their primary objective is restoring functionality immediately, contrasting with preventive maintenance teams that focus on scheduled inspections and upkeep to avoid emergencies.

Defining Preventive Maintenance Teams

Preventive maintenance teams focus on regularly scheduled inspections and repairs to proactively address potential equipment failures, minimizing unexpected downtime and extending machinery lifespan. These teams utilize data-driven maintenance schedules and predictive analytics to ensure optimal system performance and reduce emergency repair incidents. Their proactive approach contrasts with emergency repair crews, who react to equipment breakdowns after failures occur.

Core Responsibilities Compared

Emergency repair crews specialize in rapid response to unexpected equipment breakdowns, aiming to minimize downtime and restore functionality as quickly as possible. Preventive maintenance teams focus on scheduled inspections, routine servicing, and early detection of potential issues to avoid disruptions and extend asset lifespan. Both teams play crucial roles in operational reliability, with emergency crews addressing immediate failures and preventive teams ensuring long-term system health.

Skills and Training Requirements

Emergency Repair Crew members must possess advanced diagnostic skills and rapid-response training to address unforeseen faults and minimize downtime efficiently. Preventive Maintenance Team personnel require expertise in systematic inspection techniques, predictive analytics, and routine servicing protocols to prevent equipment failures proactively. Both teams necessitate ongoing certification updates and hands-on training to stay current with evolving technologies and safety standards in repair operations.

Response Time and Availability

Emergency repair crews specialize in rapid response with availability 24/7 to address urgent failures, minimizing downtime through immediate intervention. Preventive maintenance teams operate on scheduled routines, focusing on regular inspections and repairs to avert breakdowns, which results in longer but predictable response times. Prioritizing emergency crews improves system reliability by reducing critical downtime, while preventive teams enhance long-term asset performance through consistent care.

Tools and Technology Used

Emergency repair crews rely on portable diagnostic tools, hydraulic lifts, and thermal imaging cameras to quickly identify and fix urgent issues under pressure. Preventive maintenance teams utilize predictive analytics software, IoT sensors, and specialized lubrication equipment to monitor asset performance and prevent failures before they occur. Advanced technologies like augmented reality glasses are increasingly integrated into both teams' workflows to enhance efficiency and accuracy during repairs and routine inspections.

Workflow and Standard Procedures

Emergency repair crews prioritize rapid response and troubleshooting under high-pressure situations, following standardized protocols designed for immediate hazard assessment and quick restoration of critical systems. Preventive maintenance teams execute scheduled inspections, routine servicing, and system optimizations based on detailed checklists and manufacturer guidelines to prevent equipment failures and extend asset lifespan. Workflow for emergency teams is reactive with intensive documentation for root cause analysis, whereas preventive teams maintain a proactive, systematic approach emphasizing data-driven maintenance planning and compliance with safety standards.

Impact on Downtime and Productivity

Emergency repair crews rapidly restore operations after unexpected failures, minimizing downtime spikes but often causing prolonged productivity losses due to reactive fixes. Preventive maintenance teams systematically perform scheduled inspections and repairs, significantly reducing unplanned outages and sustaining higher overall productivity levels. Integrating preventive maintenance with responsive emergency repair strategies optimizes equipment uptime and enhances operational efficiency.

Cost Implications for Employers

Emergency repair crews generate higher costs due to unplanned downtime, overtime wages, and expedited parts shipping, which can significantly disrupt business operations. Preventive maintenance teams reduce long-term expenses by addressing potential issues before failure, minimizing equipment downtime and extending asset lifespan. Employers benefit financially from investing in preventive maintenance through fewer emergency repairs, increased productivity, and lower overall repair costs.

Choosing the Right Team for the Job

Emergency repair crews excel in addressing urgent breakdowns, minimizing downtime through rapid response and immediate fixes. Preventive maintenance teams specialize in routine inspections and upkeep, enhancing long-term equipment reliability and reducing unexpected failures. Selecting the right team depends on whether the priority is swift restoration of functionality or sustained operational efficiency through proactive care.

Emergency Repair Crew vs Preventive Maintenance Team Infographic

jobdiv.com

jobdiv.com