Mechanical repair focuses on restoring the functionality of a pet's moving parts, such as joints and limbs, ensuring smooth motion and proper strength. Structural repair, on the other hand, addresses the integrity of the pet's body framework, including bones and connective tissues, to maintain stability and overall support. Both types of repair are critical for full recovery and long-term health, targeting different aspects of the pet's physical condition.

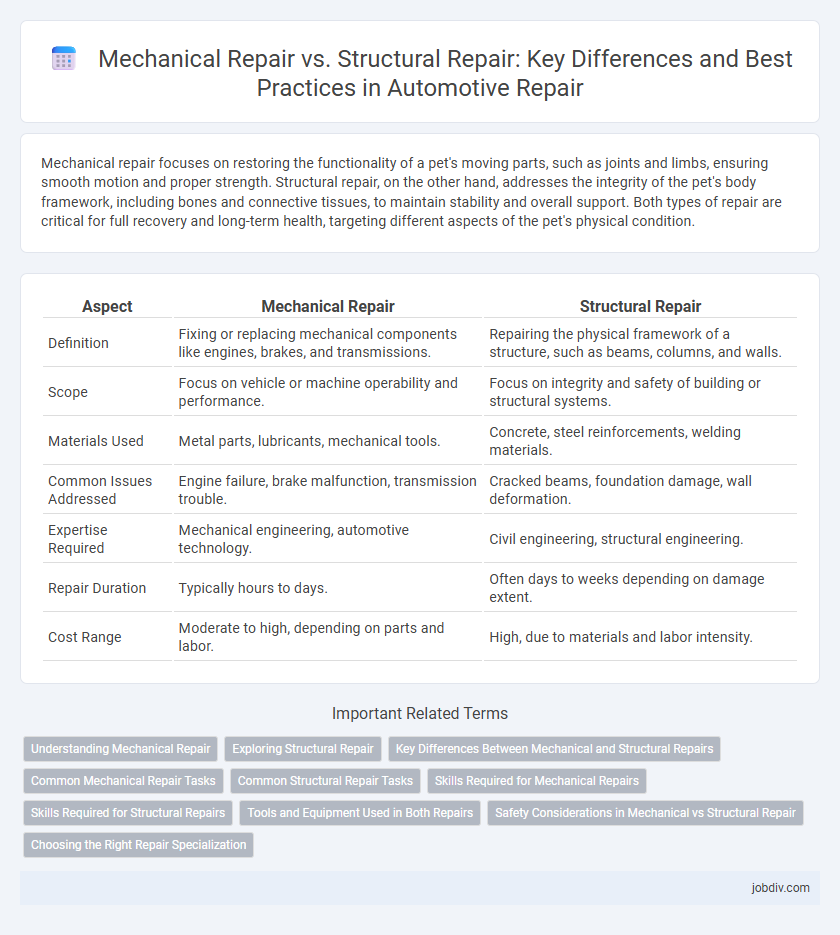

Table of Comparison

| Aspect | Mechanical Repair | Structural Repair |

|---|---|---|

| Definition | Fixing or replacing mechanical components like engines, brakes, and transmissions. | Repairing the physical framework of a structure, such as beams, columns, and walls. |

| Scope | Focus on vehicle or machine operability and performance. | Focus on integrity and safety of building or structural systems. |

| Materials Used | Metal parts, lubricants, mechanical tools. | Concrete, steel reinforcements, welding materials. |

| Common Issues Addressed | Engine failure, brake malfunction, transmission trouble. | Cracked beams, foundation damage, wall deformation. |

| Expertise Required | Mechanical engineering, automotive technology. | Civil engineering, structural engineering. |

| Repair Duration | Typically hours to days. | Often days to weeks depending on damage extent. |

| Cost Range | Moderate to high, depending on parts and labor. | High, due to materials and labor intensity. |

Understanding Mechanical Repair

Mechanical repair involves restoring the functionality of moving parts within machines or vehicles, such as engines, transmissions, and braking systems. It requires specialized knowledge of mechanical components, diagnostics, and the use of precision tools to ensure optimal performance and safety. Understanding mechanical repair emphasizes identifying wear and tear, diagnosing malfunctions, and executing repairs that extend the lifespan of mechanical systems.

Exploring Structural Repair

Structural repair involves restoring the integrity and stability of a building's framework by addressing issues such as foundation cracks, compromised load-bearing walls, or damaged beams. Unlike mechanical repair, which focuses on fixing equipment and moving parts, structural repair requires expertise in assessing and reinforcing critical components to ensure safety and prevent further deterioration. Techniques in structural repair include underpinning, steel reinforcement, and epoxy injection to effectively restore durability and function.

Key Differences Between Mechanical and Structural Repairs

Mechanical repair involves fixing or replacing moving parts and machinery components such as engines, gears, and electrical systems, ensuring proper functionality and performance. Structural repair addresses damage or deterioration in load-bearing elements like beams, columns, walls, and foundations to maintain building integrity and safety. Key differences revolve around the focus on operational systems in mechanical repair versus the reinforcement or restoration of the physical framework in structural repair.

Common Mechanical Repair Tasks

Common mechanical repair tasks include fixing engines, replacing worn-out bearings, and repairing transmission systems to restore vehicle or equipment functionality. These repairs often involve diagnosing mechanical failures, adjusting or replacing components like belts, gears, and pumps, and ensuring proper lubrication and alignment for optimal performance. Mechanical repairs focus on moving parts and systems, distinguishing them from structural repairs which address the integrity of the framework or body.

Common Structural Repair Tasks

Common structural repair tasks involve addressing issues such as foundation settlement, cracked walls, and damaged load-bearing beams to restore the integrity and safety of a building. These repairs typically require specialized expertise in masonry, welding, and concrete reinforcement to ensure long-lasting stability. Proper assessment and timely intervention in structural repairs prevent further deterioration and costly future damage.

Skills Required for Mechanical Repairs

Mechanical repairs demand proficiency in diagnosing engine systems, hydraulic components, and electrical circuits to restore operational functionality efficiently. Technicians must possess skills in precision measurement, welding, and the use of diagnostic tools such as multimeters and computerized scanners. Advanced knowledge of mechanical theory and hands-on experience with vehicle or machinery parts are essential for effective mechanical repair outcomes.

Skills Required for Structural Repairs

Structural repair demands advanced skills in material science, welding, and load analysis, ensuring the integrity and stability of critical frameworks. Precision in assessing damage and implementing reinforcements is essential to prevent future failures and maintain safety standards. Proficiency in interpreting engineering blueprints and compliance with construction codes distinguishes structural repair specialists from those performing general mechanical repairs.

Tools and Equipment Used in Both Repairs

Mechanical repair typically involves precision tools such as wrenches, torque tools, diagnostic scanners, and hydraulic jacks to service engines, transmissions, and other moving parts. Structural repair requires heavy-duty equipment including welding machines, grinders, cranes, and frame straightening tools to address damage to the vehicle's chassis or framework. Both repairs demand specialized tools tailored to either mechanical components or structural integrity to ensure safety and functionality.

Safety Considerations in Mechanical vs Structural Repair

Mechanical repair prioritizes the safety of moving parts and machinery by addressing wear, alignment, and lubrication issues to prevent operational failures and accidents. Structural repair focuses on maintaining the integrity of load-bearing elements such as beams, columns, and foundations to ensure the overall stability and safety of the building or infrastructure. Safety protocols in mechanical repairs often involve machinery lockout/tagout procedures, while structural repairs require rigorous assessment of material strength and compliance with building codes to mitigate collapse risks.

Choosing the Right Repair Specialization

Selecting the appropriate repair specialization depends on accurately diagnosing whether the issue pertains to mechanical systems, such as engines or transmissions, or structural components like frames and chassis. Mechanical repair requires expertise in engine diagnostics, fluid replacements, and component overhauls, while structural repair focuses on welding, alignment, and body integrity restoration. Properly distinguishing between mechanical and structural repair ensures targeted solutions that restore functionality and safety effectively.

Mechanical Repair vs Structural Repair Infographic

jobdiv.com

jobdiv.com