Plumbing repair primarily involves fixing leaks, clogs, and other issues within household water systems to ensure proper water flow and sanitation. Pipefitting repair, on the other hand, deals with the installation and maintenance of high-pressure pipelines often found in industrial settings, requiring specialized knowledge of materials and welding techniques. Understanding the distinction helps homeowners and businesses choose the right professional for efficient and durable pipe solutions.

Table of Comparison

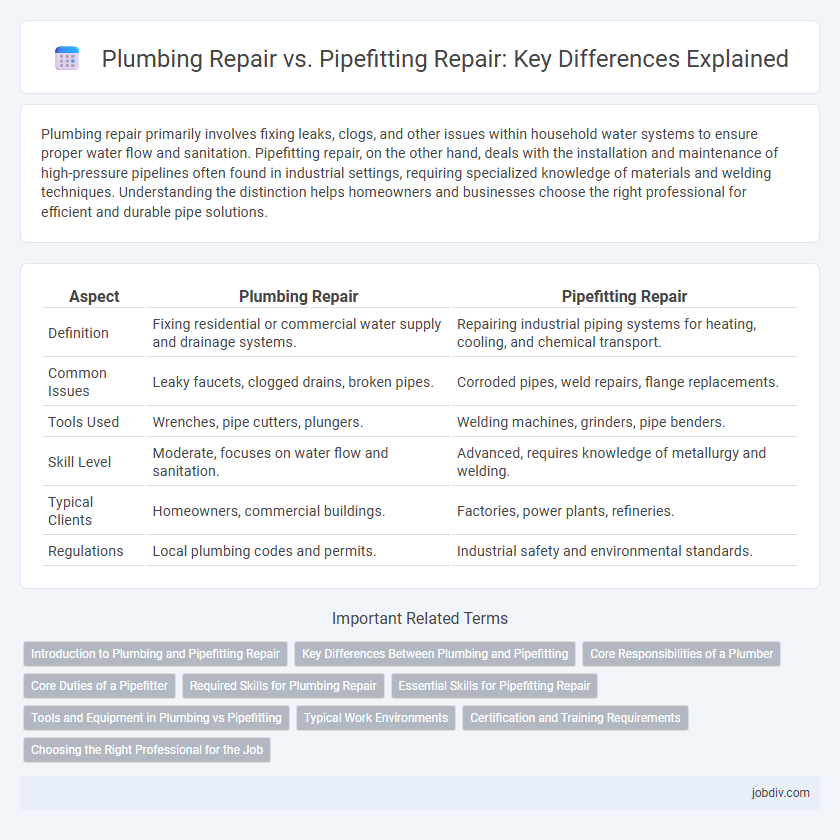

| Aspect | Plumbing Repair | Pipefitting Repair |

|---|---|---|

| Definition | Fixing residential or commercial water supply and drainage systems. | Repairing industrial piping systems for heating, cooling, and chemical transport. |

| Common Issues | Leaky faucets, clogged drains, broken pipes. | Corroded pipes, weld repairs, flange replacements. |

| Tools Used | Wrenches, pipe cutters, plungers. | Welding machines, grinders, pipe benders. |

| Skill Level | Moderate, focuses on water flow and sanitation. | Advanced, requires knowledge of metallurgy and welding. |

| Typical Clients | Homeowners, commercial buildings. | Factories, power plants, refineries. |

| Regulations | Local plumbing codes and permits. | Industrial safety and environmental standards. |

Introduction to Plumbing and Pipefitting Repair

Plumbing repair involves fixing water supply and drainage systems, addressing issues like leaks, clogged drains, and pipe corrosion to ensure efficient water flow in residential and commercial properties. Pipefitting repair focuses on assembling, installing, and maintaining high-pressure piping systems used in industrial settings, including steam, gas, and chemical lines, requiring specialized tools and technical skills. Both trades are essential for maintaining infrastructure integrity but differ in application, scale, and complexity of the piping systems handled.

Key Differences Between Plumbing and Pipefitting

Plumbing repair primarily involves the installation and maintenance of water supply and waste disposal systems in residential and commercial buildings, focusing on fixtures such as sinks, toilets, and water heaters. Pipefitting repair centers on industrial piping systems that transport chemicals, gases, and high-pressure steam, requiring specialized skills for handling complex materials like stainless steel and copper alloys. Key differences include the scope of work, with plumbing addressing everyday water systems and pipefitting dealing with high-pressure, industrial environments requiring precise measurement and welding techniques.

Core Responsibilities of a Plumber

Plumbers specialize in installing, repairing, and maintaining water supply lines, drainage systems, and fixtures such as sinks, toilets, and water heaters. They diagnose and fix leaks, blockages, and pipe corrosion to ensure proper water flow and prevent structural damage. Unlike pipefitters who work mainly with high-pressure industrial piping systems, plumbers focus on residential and commercial plumbing infrastructure essential for daily water use.

Core Duties of a Pipefitter

Pipefitting repair primarily involves installing, maintaining, and repairing high-pressure piping systems used in industrial settings, such as power plants and manufacturing facilities. Core duties include reading blueprints, welding pipes, and ensuring system integrity under extreme temperatures and pressures. Unlike general plumbing repair, pipefitters handle complex configurations requiring specialized tools and compliance with rigorous safety standards.

Required Skills for Plumbing Repair

Plumbing repair requires expertise in diagnosing leaks, unclogging drains, and repairing or replacing pipes, faucets, and fixtures, emphasizing knowledge of water supply systems and proper sealing techniques. It demands proficiency in reading blueprints, using specialized tools like pipe wrenches and augers, and adhering to local plumbing codes to ensure safety and functionality. Technical skills in soldering copper pipes and installing valves are essential for effective plumbing repair and maintenance.

Essential Skills for Pipefitting Repair

Pipefitting repair demands essential skills such as precision in measuring and cutting pipes, proficiency in interpreting complex blueprints, and expertise in welding and soldering techniques to ensure secure pipe connections. Mastery of materials like steel, copper, and plastic is crucial for effective pipefitting repairs in industrial and commercial settings. Advanced troubleshooting skills are necessary to identify and resolve issues like leaks, blockages, and pressure problems within intricate piping systems.

Tools and Equipment in Plumbing vs Pipefitting

Plumbing repair relies heavily on tools such as pipe wrenches, plungers, augers, and soldering torches to address residential and commercial water supply and drainage issues. Pipefitting repair requires more specialized equipment including pipe threading machines, welding gear, and hydrostatic testing devices to assemble and maintain high-pressure piping systems in industrial settings. The precision and durability of pipefitting tools contrast with the more general-use tools commonly found in plumbing repair, reflecting their distinct applications and environments.

Typical Work Environments

Plumbing repair typically takes place in residential and commercial buildings, including kitchens, bathrooms, and HVAC systems, where the focus is on water supply and waste removal. Pipefitting repair is commonly performed in industrial environments such as factories, refineries, and power plants, involving high-pressure systems and complex piping networks for gas, steam, and chemicals. Each work environment demands specialized tools and safety protocols suited to the specific materials and operational conditions of the piping systems.

Certification and Training Requirements

Plumbing repair technicians typically require state-issued licenses and completion of apprenticeships or technical school programs focusing on residential and commercial water systems. Pipefitting repair professionals must often attain specialized certifications such as those from the National Center for Construction Education and Research (NCCER) and undergo extensive training in industrial piping, welding, and high-pressure systems. Both fields demand rigorous safety training, but pipefitting repair emphasizes advanced skills for handling complex mechanical systems in industrial environments.

Choosing the Right Professional for the Job

Selecting the right expert for plumbing repair versus pipefitting repair depends on the specific issue and system requirements. Plumbing repair specialists handle residential and commercial water systems, including leaks and fixture installations, while pipefitters focus on industrial piping systems for gases, chemicals, and high-pressure liquids. Understanding the scope of work and system type ensures efficient repairs and system longevity by aligning expertise with job complexity.

Plumbing Repair vs Pipefitting Repair Infographic

jobdiv.com

jobdiv.com