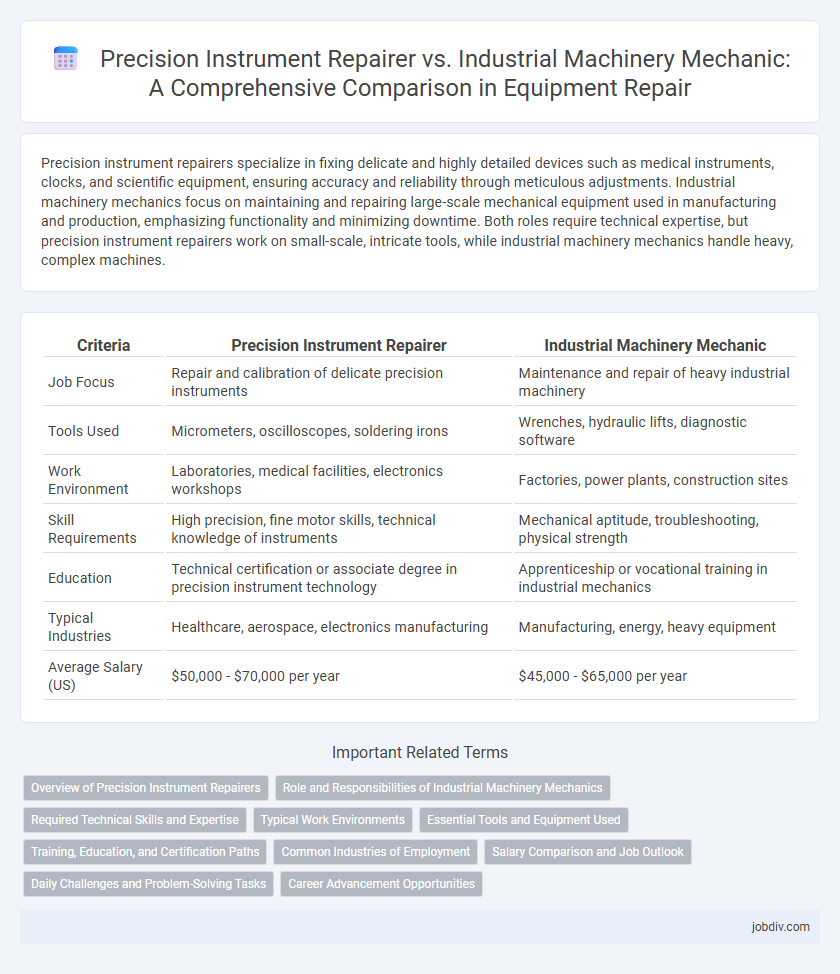

Precision instrument repairers specialize in fixing delicate and highly detailed devices such as medical instruments, clocks, and scientific equipment, ensuring accuracy and reliability through meticulous adjustments. Industrial machinery mechanics focus on maintaining and repairing large-scale mechanical equipment used in manufacturing and production, emphasizing functionality and minimizing downtime. Both roles require technical expertise, but precision instrument repairers work on small-scale, intricate tools, while industrial machinery mechanics handle heavy, complex machines.

Table of Comparison

| Criteria | Precision Instrument Repairer | Industrial Machinery Mechanic |

|---|---|---|

| Job Focus | Repair and calibration of delicate precision instruments | Maintenance and repair of heavy industrial machinery |

| Tools Used | Micrometers, oscilloscopes, soldering irons | Wrenches, hydraulic lifts, diagnostic software |

| Work Environment | Laboratories, medical facilities, electronics workshops | Factories, power plants, construction sites |

| Skill Requirements | High precision, fine motor skills, technical knowledge of instruments | Mechanical aptitude, troubleshooting, physical strength |

| Education | Technical certification or associate degree in precision instrument technology | Apprenticeship or vocational training in industrial mechanics |

| Typical Industries | Healthcare, aerospace, electronics manufacturing | Manufacturing, energy, heavy equipment |

| Average Salary (US) | $50,000 - $70,000 per year | $45,000 - $65,000 per year |

Overview of Precision Instrument Repairers

Precision Instrument Repairers specialize in diagnosing, calibrating, and repairing sensitive and complex devices such as measuring instruments, medical equipment, and optical machinery, ensuring critical accuracy and functionality. Their expertise encompasses electronic, mechanical, and optical systems, requiring precision in adjustments and detailed knowledge of technology standards. Unlike Industrial Machinery Mechanics who focus on large-scale mechanical systems primarily in manufacturing environments, Precision Instrument Repairers work with instruments crucial for scientific research, healthcare, and high-tech industries.

Role and Responsibilities of Industrial Machinery Mechanics

Industrial Machinery Mechanics specialize in diagnosing, repairing, and maintaining complex machinery used in manufacturing and production facilities, ensuring equipment operates efficiently to minimize downtime. They interpret blueprints and technical manuals to disassemble and reassemble heavy machinery components, perform preventative maintenance, and replace defective parts. Their expertise supports uninterrupted industrial operations, significantly contributing to workplace safety and productivity.

Required Technical Skills and Expertise

Precision instrument repairers demand advanced knowledge of calibration, micro-mechanics, and electronic diagnostics to maintain and restore sensitive devices with exact accuracy. Industrial machinery mechanics require expertise in hydraulics, pneumatics, and heavy equipment troubleshooting to efficiently repair and maintain large-scale manufacturing machinery. Both roles necessitate strong problem-solving abilities, but precision instrument repairers concentrate more on intricate, finely-tuned components, while industrial mechanics focus on robust mechanical systems.

Typical Work Environments

Precision instrument repairers often work in clean, well-lit laboratories or manufacturing facilities where delicate instruments require meticulous handling and calibration. In contrast, industrial machinery mechanics primarily operate in industrial plants, factories, or construction sites, managing larger, heavy-duty machinery under more physically demanding and sometimes hazardous conditions. Both roles require specialized knowledge, but the work environments significantly differ in scale, cleanliness, and exposure to industrial hazards.

Essential Tools and Equipment Used

Precision instrument repairers primarily use specialized hand tools such as micrometers, calipers, soldering irons, and precision screwdrivers to calibrate and repair delicate instruments with high accuracy. Industrial machinery mechanics rely on heavy-duty equipment including hydraulic lifts, pneumatic wrenches, torque wrenches, and diagnostic software tools to maintain and repair large-scale manufacturing machinery. Both professionals require multimeters and oscilloscopes, but the scale and precision of tools differ significantly based on the complexity and size of equipment they service.

Training, Education, and Certification Paths

Precision instrument repairers typically undergo specialized technical training through vocational schools or community colleges, often earning certificates or associate degrees focused on fine mechanics and electronics. Industrial machinery mechanics usually complete apprenticeships combined with coursework in industrial maintenance, machinery systems, and hydraulics, often leading to certifications like the Industrial Maintenance Technician credential. Both careers benefit from certifications such as those offered by the National Institute for Certification in Engineering Technologies (NICET), enhancing qualifications and job prospects.

Common Industries of Employment

Precision instrument repairers commonly find employment in industries such as medical equipment manufacturing, aerospace, electronics, and scientific research laboratories, where maintaining accuracy and functionality is critical. Industrial machinery mechanics are typically employed in manufacturing plants, automotive production, and heavy machinery industries, performing maintenance and repairs to ensure operational efficiency. Both professions are essential in sectors like energy production and transportation, where reliable equipment performance is vital.

Salary Comparison and Job Outlook

Precision instrument repairers earn a median annual wage of approximately $51,000, reflecting the demand for specialized skills in maintaining delicate instruments. Industrial machinery mechanics report a higher median salary near $56,000, driven by the extensive need for machinery upkeep in manufacturing sectors. Employment growth for precision instrument repairers is projected at 4% over the next decade, while industrial machinery mechanics are expected to experience a slightly faster growth rate of 6%, highlighting stronger job opportunities in industrial settings.

Daily Challenges and Problem-Solving Tasks

Precision instrument repairers frequently face daily challenges involving delicate calibration and fine-tuning of complex devices like optical instruments and measuring tools, requiring exceptional attention to detail and steady hands. Industrial machinery mechanics often encounter heavy machinery breakdowns, necessitating troubleshooting hydraulic systems, electrical controls, and mechanical components under time constraints to minimize operational downtime. Both professions demand advanced diagnostic skills and problem-solving abilities to maintain equipment accuracy and functionality in high-stakes industrial environments.

Career Advancement Opportunities

Precision instrument repairers often experience faster career advancement by specializing in high-tech medical, optical, or scientific equipment, leveraging their expertise in calibration and fine adjustments. Industrial machinery mechanics typically progress through diverse manufacturing sectors, gaining opportunities in complex machinery diagnostics and maintenance leadership roles. Advanced certifications and continuous technical training significantly enhance career growth potential in both precision instruments and industrial machinery repair fields.

Precision Instrument Repairer vs Industrial Machinery Mechanic Infographic

jobdiv.com

jobdiv.com