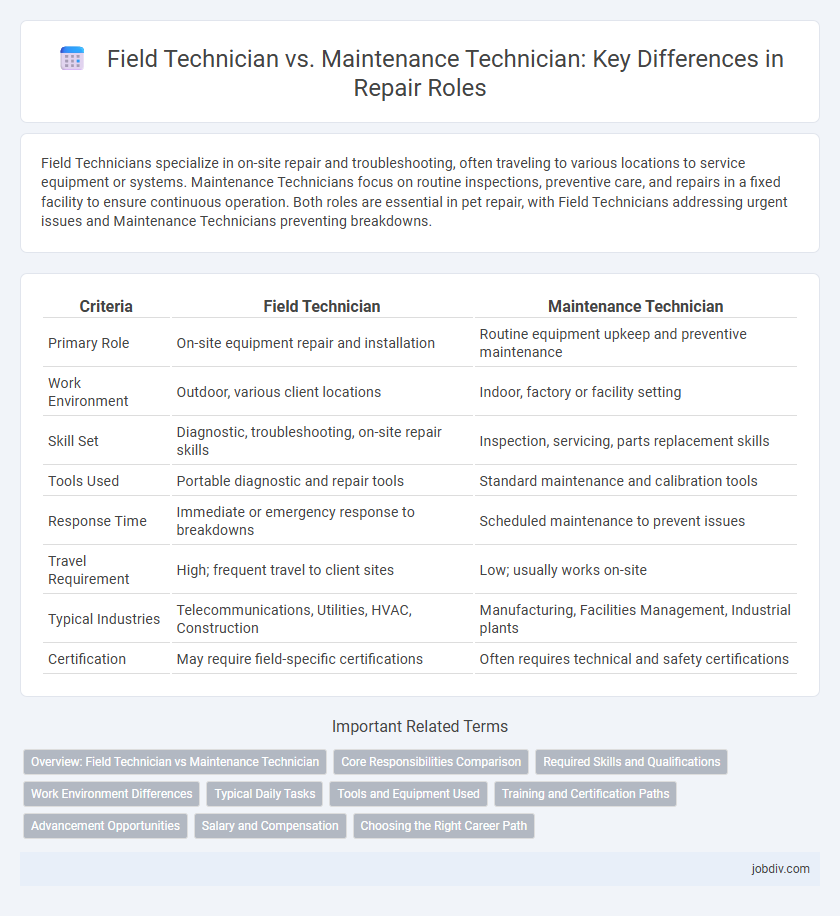

Field Technicians specialize in on-site repair and troubleshooting, often traveling to various locations to service equipment or systems. Maintenance Technicians focus on routine inspections, preventive care, and repairs in a fixed facility to ensure continuous operation. Both roles are essential in pet repair, with Field Technicians addressing urgent issues and Maintenance Technicians preventing breakdowns.

Table of Comparison

| Criteria | Field Technician | Maintenance Technician |

|---|---|---|

| Primary Role | On-site equipment repair and installation | Routine equipment upkeep and preventive maintenance |

| Work Environment | Outdoor, various client locations | Indoor, factory or facility setting |

| Skill Set | Diagnostic, troubleshooting, on-site repair skills | Inspection, servicing, parts replacement skills |

| Tools Used | Portable diagnostic and repair tools | Standard maintenance and calibration tools |

| Response Time | Immediate or emergency response to breakdowns | Scheduled maintenance to prevent issues |

| Travel Requirement | High; frequent travel to client sites | Low; usually works on-site |

| Typical Industries | Telecommunications, Utilities, HVAC, Construction | Manufacturing, Facilities Management, Industrial plants |

| Certification | May require field-specific certifications | Often requires technical and safety certifications |

Overview: Field Technician vs Maintenance Technician

Field Technicians specialize in on-site repair and troubleshooting of equipment, often working in diverse environments to ensure operational continuity. Maintenance Technicians focus on routine inspections, preventive maintenance, and equipment upgrades within a controlled facility, minimizing downtime. Both roles require technical expertise, but Field Technicians prioritize mobility and adaptability while Maintenance Technicians emphasize systematic upkeep and long-term reliability.

Core Responsibilities Comparison

Field technicians specialize in on-site troubleshooting, installation, and urgent repairs of equipment, often requiring travel to various client locations. Maintenance technicians focus on routine inspections, preventive maintenance, and calibration tasks within a fixed facility to ensure long-term equipment reliability. Both roles demand technical expertise, but field technicians address immediate operational disruptions while maintenance technicians prioritize sustained system performance.

Required Skills and Qualifications

Field technicians require strong troubleshooting abilities, proficiency with diagnostic tools, and excellent communication skills for on-site customer interactions. Maintenance technicians must possess in-depth knowledge of mechanical and electrical systems, preventive maintenance techniques, and the ability to read technical manuals and schematics. Both roles demand certifications such as OSHA safety training, but field technicians often need additional soft skills for dynamic environments, while maintenance technicians prioritize technical expertise and routine system upkeep.

Work Environment Differences

Field Technicians typically work on-site at customer locations, encountering varied environments such as outdoor settings, industrial plants, or remote areas, which require adaptability to weather and space constraints. Maintenance Technicians are primarily based in controlled indoor settings like manufacturing facilities or corporate campuses, focusing on routine equipment inspections and repairs within a stable environment. The dynamic nature of a Field Technician's work contrasts with the predictable, scheduled tasks of Maintenance Technicians, influencing safety protocols and toolkits.

Typical Daily Tasks

Field technicians primarily handle on-site repairs and installations, diagnosing equipment issues at customer locations, and ensuring timely resolution of technical problems. Maintenance technicians focus on routine inspections, preventive maintenance, and troubleshooting within a facility, aiming to minimize equipment downtime and extend machinery lifespan. Both roles require specialized technical skills but differ in environment and scope of responsibilities to optimize operational efficiency.

Tools and Equipment Used

Field Technicians rely on portable diagnostic tools and multimeters to troubleshoot equipment on-site, ensuring quick repairs in diverse environments. Maintenance Technicians typically use calibrated hand tools, lubrication systems, and preventive maintenance equipment to sustain optimal machinery function within controlled settings. Both roles require specialized instruments, but Field Technicians emphasize mobility and adaptability, while Maintenance Technicians prioritize precision and routine equipment care.

Training and Certification Paths

Field Technicians typically undergo specialized training programs focused on on-site diagnostics, repair skills, and customer interaction, often requiring certifications like CompTIA A+ or NATE for HVAC systems. Maintenance Technicians prioritize certification in preventive maintenance, machinery operation, and safety protocols, frequently obtaining credentials such as OSHA Safety Certification or Certified Maintenance & Reliability Technician (CMRT). Both roles benefit from ongoing professional development, but Field Technicians emphasize mobility and troubleshooting, whereas Maintenance Technicians focus on system longevity and reliability.

Advancement Opportunities

Field technicians often have broader advancement opportunities through roles in project management, system design, or specialized technical consulting due to their diverse hands-on experience in various environments. Maintenance technicians typically advance by deepening expertise in specific machinery or systems, leading to supervisory positions or roles in predictive maintenance and reliability engineering. Both paths offer growth, but field technicians may experience faster career progression in dynamic and client-facing industries.

Salary and Compensation

Field technicians typically earn an average salary ranging from $45,000 to $65,000 annually, with variations based on geographic location and industry specialization. Maintenance technicians generally receive a median salary between $40,000 and $60,000 per year, often supplemented by overtime pay and shift differentials. Compensation packages for field technicians may include travel allowances and per diem, whereas maintenance technicians frequently benefit from steady hours and company-provided certifications.

Choosing the Right Career Path

Field technicians specialize in on-site repairs and installations, requiring strong problem-solving skills and adaptability to diverse environments. Maintenance technicians focus on preventive maintenance and routine inspections within facilities, emphasizing technical knowledge and equipment upkeep. Choosing the right career path depends on preference for dynamic fieldwork or structured facility-based roles, aligning with individual strengths and career goals.

Field Technician vs Maintenance Technician Infographic

jobdiv.com

jobdiv.com