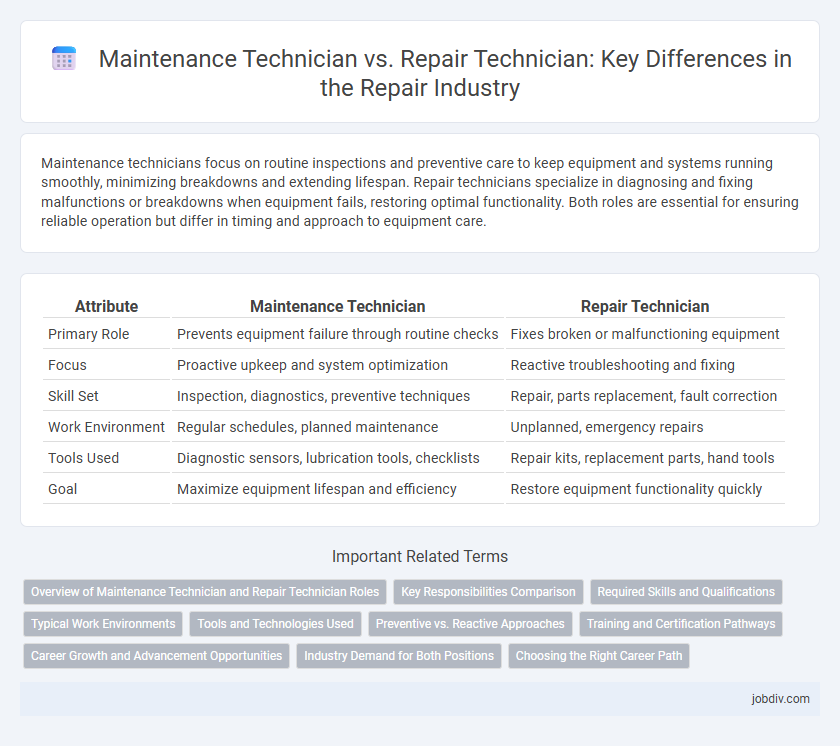

Maintenance technicians focus on routine inspections and preventive care to keep equipment and systems running smoothly, minimizing breakdowns and extending lifespan. Repair technicians specialize in diagnosing and fixing malfunctions or breakdowns when equipment fails, restoring optimal functionality. Both roles are essential for ensuring reliable operation but differ in timing and approach to equipment care.

Table of Comparison

| Attribute | Maintenance Technician | Repair Technician |

|---|---|---|

| Primary Role | Prevents equipment failure through routine checks | Fixes broken or malfunctioning equipment |

| Focus | Proactive upkeep and system optimization | Reactive troubleshooting and fixing |

| Skill Set | Inspection, diagnostics, preventive techniques | Repair, parts replacement, fault correction |

| Work Environment | Regular schedules, planned maintenance | Unplanned, emergency repairs |

| Tools Used | Diagnostic sensors, lubrication tools, checklists | Repair kits, replacement parts, hand tools |

| Goal | Maximize equipment lifespan and efficiency | Restore equipment functionality quickly |

Overview of Maintenance Technician and Repair Technician Roles

Maintenance technicians focus on preventive measures by regularly inspecting and servicing equipment to ensure operational efficiency and minimize breakdowns. Repair technicians specialize in diagnosing and fixing malfunctioning machinery or systems, restoring them to working order after failures occur. Both roles require technical expertise, but maintenance technicians emphasize routine upkeep, while repair technicians handle corrective actions.

Key Responsibilities Comparison

Maintenance technicians focus on preventive measures such as routine inspections, lubrication, and calibrations to ensure equipment operates efficiently and to minimize downtime. Repair technicians specialize in diagnosing faults, replacing defective components, and restoring machinery to full functionality after breakdowns or failures. Both roles require technical expertise, but maintenance emphasizes ongoing upkeep, while repair prioritizes corrective actions post-malfunction.

Required Skills and Qualifications

Maintenance Technicians require proficiency in preventive maintenance, mechanical systems, electrical troubleshooting, and the ability to interpret technical manuals to ensure optimal equipment performance. Repair Technicians must possess strong diagnostic skills, expertise in fault detection, and experience with repair tools and techniques to restore machinery to operational condition quickly. Both roles typically demand certifications in relevant technical fields, hands-on experience, and a solid understanding of safety protocols.

Typical Work Environments

Maintenance technicians typically work in manufacturing plants, industrial facilities, and commercial buildings, ensuring machinery and equipment operate smoothly through routine inspections and preventive measures. Repair technicians are commonly found in automotive shops, electronics service centers, and residential settings, focusing on troubleshooting and fixing specific equipment malfunctions or breakdowns. Both roles may involve on-site visits but differ in the balance between proactive maintenance and reactive repair tasks.

Tools and Technologies Used

Maintenance technicians primarily use diagnostic tools such as multimeters, calibration devices, and preventive maintenance software to ensure equipment operates efficiently, while repair technicians rely heavily on specialized hand tools, welding equipment, and replacement parts to fix breakdowns. Maintenance technicians often utilize predictive maintenance technologies like vibration analyzers and thermal imaging cameras to detect potential issues before failure, whereas repair technicians focus on troubleshooting tools such as oscilloscopes and soldering stations to restore malfunctioning systems. Both roles require proficiency in computer-based maintenance management systems (CMMS) but differ in their emphasis on monitoring versus hands-on repair technologies.

Preventive vs. Reactive Approaches

Maintenance Technicians specialize in preventive approaches, performing routine inspections and upkeep to avoid equipment failures and extend machinery lifespan. Repair Technicians focus on reactive methods, diagnosing and fixing issues after malfunctions occur to restore operational functionality. Prioritizing preventive maintenance reduces downtime and repair costs compared to reactive repairs that address unexpected breakdowns.

Training and Certification Pathways

Maintenance technicians often pursue certifications like Certified Maintenance and Reliability Technician (CMRT) or HVAC certifications, emphasizing preventive care and system optimization. Repair technicians typically focus on diagnostic skills with certifications such as Industrial Maintenance Technician or Electrical Repair Specialist, highlighting fault detection and component replacement. Training pathways for maintenance roles prioritize routine inspection and system upkeep, while repair training centers on troubleshooting and corrective actions to restore equipment functionality.

Career Growth and Advancement Opportunities

Maintenance Technicians often have broader career growth opportunities due to their involvement in preventative care, equipment optimization, and cross-functional skills development, which are highly valued in manufacturing and industrial sectors. Repair Technicians may progress by specializing in complex diagnostics and advanced repair techniques, often leading to roles such as senior technician or technical instructor. Both career paths offer advancement potential, but Maintenance Technicians generally experience faster upward mobility through exposure to diverse maintenance strategies and reliability engineering practices.

Industry Demand for Both Positions

Maintenance technicians and repair technicians are both crucial in industrial settings, with maintenance technicians focusing on preventive upkeep to minimize downtime and repair technicians specializing in fixing equipment failures. Industry demand for maintenance technicians is rising due to the growing emphasis on predictive maintenance technologies and reducing operational costs. Repair technicians remain essential for addressing unexpected breakdowns, but the shift toward proactive maintenance strategies is driving increased hiring for maintenance roles across manufacturing, energy, and transportation sectors.

Choosing the Right Career Path

Maintenance technicians specialize in preventive care, regularly inspecting and servicing equipment to avoid breakdowns and extend machinery lifespan. Repair technicians focus on diagnosing and fixing equipment failures when issues arise, requiring strong troubleshooting skills and the ability to work under pressure. Choosing the right career path depends on whether you prefer proactive maintenance routines or reactive problem-solving tasks within technical environments.

Maintenance Technician vs Repair Technician Infographic

jobdiv.com

jobdiv.com