Wiring repair involves fixing or replacing damaged electrical wires to restore proper connections in pet devices, while PCB trace repair targets the delicate conductive pathways on the circuit board itself. PCB trace repair requires precision and specialized tools to mend broken or corroded traces without compromising the board's integrity. Choosing between wiring repair and PCB trace repair depends on the location of the damage and the complexity of the device's circuitry.

Table of Comparison

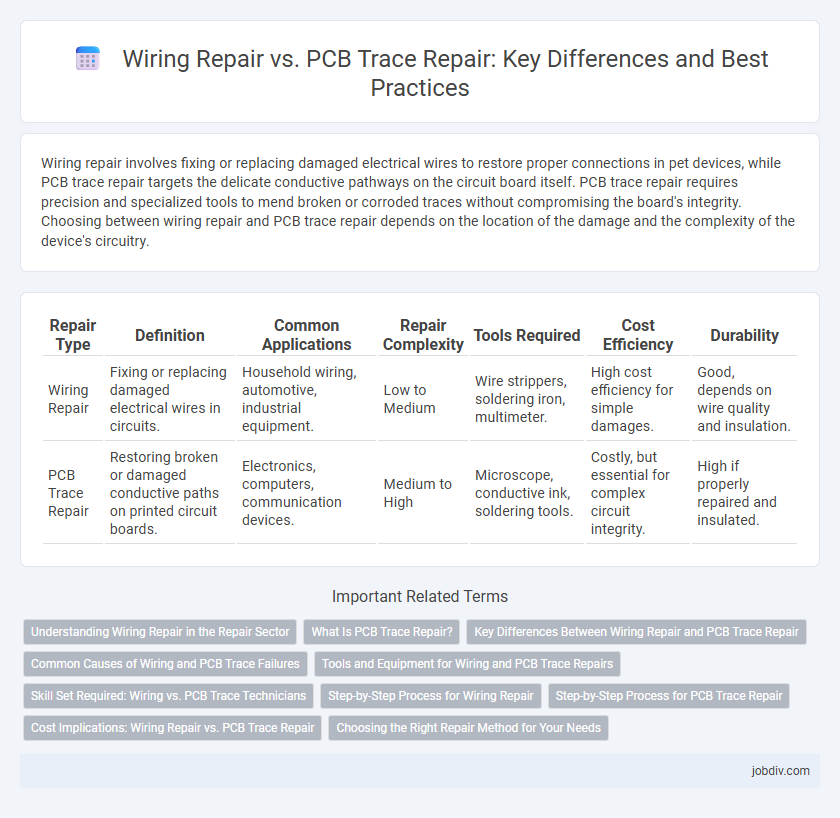

| Repair Type | Definition | Common Applications | Repair Complexity | Tools Required | Cost Efficiency | Durability |

|---|---|---|---|---|---|---|

| Wiring Repair | Fixing or replacing damaged electrical wires in circuits. | Household wiring, automotive, industrial equipment. | Low to Medium | Wire strippers, soldering iron, multimeter. | High cost efficiency for simple damages. | Good, depends on wire quality and insulation. |

| PCB Trace Repair | Restoring broken or damaged conductive paths on printed circuit boards. | Electronics, computers, communication devices. | Medium to High | Microscope, conductive ink, soldering tools. | Costly, but essential for complex circuit integrity. | High if properly repaired and insulated. |

Understanding Wiring Repair in the Repair Sector

Wiring repair involves fixing or replacing damaged electrical wires to restore proper connectivity and functionality in electronic devices or machinery. It requires identifying faults such as breaks, shorts, or corrosion within the wiring harness and ensuring secure connections to prevent future failures. Skilled technicians use specialized tools like multimeters and wire strippers to accurately diagnose and repair wiring issues, making it a fundamental aspect of the repair sector.

What Is PCB Trace Repair?

PCB trace repair involves restoring damaged conductive pathways on a printed circuit board to maintain electrical connectivity and functionality. This process addresses issues such as broken or corroded traces caused by physical damage, overheating, or corrosion, ensuring signal integrity and device performance. Techniques include applying conductive ink, soldering jumper wires, or replacing copper traces to effectively repair circuits without replacing the entire PCB.

Key Differences Between Wiring Repair and PCB Trace Repair

Wiring repair involves fixing or replacing insulated electrical wires to restore connections in circuits, while PCB trace repair targets damaged conductive pathways on printed circuit boards. Wiring repair typically manages larger gauge conductors and mechanical stresses, whereas PCB trace repair requires precision techniques like soldering microscale traces or using conductive ink. The complexity and tools differ significantly, with wiring repair focusing on electrical continuity and insulation, and PCB trace repair emphasizing restoration of micro-circuit paths and signal integrity.

Common Causes of Wiring and PCB Trace Failures

Wiring repair and PCB trace repair commonly address failures caused by physical damage such as cuts, abrasions, or corrosion resulting from environmental exposure or mechanical stress. Electrical overloads and short circuits frequently lead to burnt or broken wires and damaged PCB traces, disrupting circuit continuity. Moisture ingress and thermal cycling can also degrade insulation and PCB substrates, causing intermittent faults and long-term reliability issues.

Tools and Equipment for Wiring and PCB Trace Repairs

Wiring repair typically requires wire strippers, multimeters, soldering irons, heat shrink tubing, and crimping tools to ensure secure electrical connections and insulation. PCB trace repair demands precision instruments such as fine-tipped soldering irons, flux, conductive ink pens, fiberglass scratch tools, and microscopes to accurately restore broken circuit paths on printed circuit boards. Both repairs benefit from quality diagnostic equipment like oscilloscopes and continuity testers to verify functionality post-repair.

Skill Set Required: Wiring vs. PCB Trace Technicians

Wiring repair requires technicians skilled in identifying and fixing electrical connections, often involving hands-on wire stripping, soldering, and insulation techniques. PCB trace repair demands specialized knowledge of circuit board layouts, precision in microscopic soldering, and expertise in diagnosing trace damage or breaks using advanced tools like multimeters and microscopes. Technicians proficient in wiring repairs generally possess broader electrical skills, while PCB trace repair specialists must master intricate repair methods specific to printed circuit board technology.

Step-by-Step Process for Wiring Repair

Wiring repair involves systematically inspecting damaged wires, stripping insulation carefully, and using connectors or soldering techniques to restore electrical continuity. The process includes testing the repaired wiring with a multimeter to ensure proper voltage and continuity before reassembly. Proper insulation and securing the wiring prevent short circuits and enhance durability in the repaired system.

Step-by-Step Process for PCB Trace Repair

PCB trace repair involves carefully identifying the damaged trace, cleaning the area with isopropyl alcohol, and using a multimeter to confirm the break. Next, apply flux and solder a thin wire or conductive paint to bridge the damaged trace, ensuring proper electrical continuity. Finally, test the repaired trace with a multimeter and reassemble the device to verify full functionality.

Cost Implications: Wiring Repair vs. PCB Trace Repair

Wiring repair typically involves replacing or reconnecting damaged cables and connectors, often resulting in lower material costs but potentially higher labor charges due to accessibility challenges. PCB trace repair requires precise techniques such as soldering or conductive ink application, which can be more time-consuming and costly due to specialized tools and expertise. Cost implications vary based on damage severity and repair complexity, with PCB trace repair generally exceeding wiring repair expenses.

Choosing the Right Repair Method for Your Needs

Wiring repair involves replacing or reconnecting damaged wires, ideal for visible or accessible faults, while PCB trace repair focuses on restoring broken or corroded conductive pathways on circuit boards, suited for intricate electronic components. Selecting the right repair method depends on factors like damage location, device complexity, and cost-effectiveness, with wiring repair often being quicker but less precise than PCB trace repair. Prioritize PCB trace repair for high-density electronics requiring precise conductivity restoration and wiring repair for straightforward connections in less complex systems.

Wiring Repair vs PCB Trace Repair Infographic

jobdiv.com

jobdiv.com