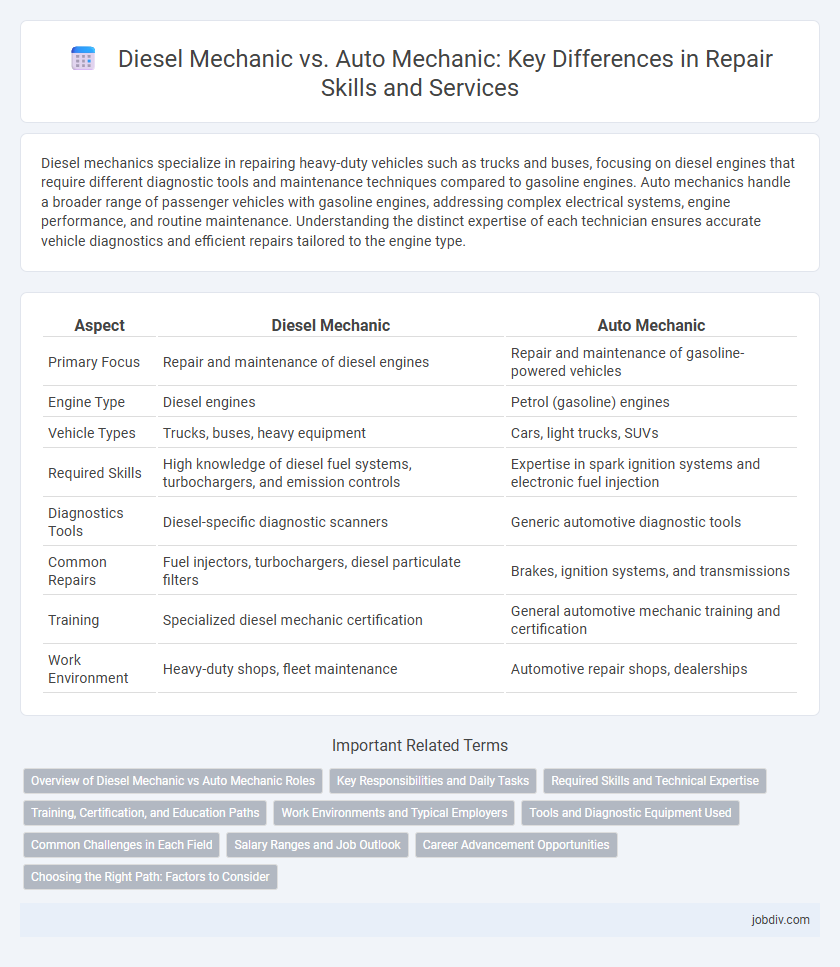

Diesel mechanics specialize in repairing heavy-duty vehicles such as trucks and buses, focusing on diesel engines that require different diagnostic tools and maintenance techniques compared to gasoline engines. Auto mechanics handle a broader range of passenger vehicles with gasoline engines, addressing complex electrical systems, engine performance, and routine maintenance. Understanding the distinct expertise of each technician ensures accurate vehicle diagnostics and efficient repairs tailored to the engine type.

Table of Comparison

| Aspect | Diesel Mechanic | Auto Mechanic |

|---|---|---|

| Primary Focus | Repair and maintenance of diesel engines | Repair and maintenance of gasoline-powered vehicles |

| Engine Type | Diesel engines | Petrol (gasoline) engines |

| Vehicle Types | Trucks, buses, heavy equipment | Cars, light trucks, SUVs |

| Required Skills | High knowledge of diesel fuel systems, turbochargers, and emission controls | Expertise in spark ignition systems and electronic fuel injection |

| Diagnostics Tools | Diesel-specific diagnostic scanners | Generic automotive diagnostic tools |

| Common Repairs | Fuel injectors, turbochargers, diesel particulate filters | Brakes, ignition systems, and transmissions |

| Training | Specialized diesel mechanic certification | General automotive mechanic training and certification |

| Work Environment | Heavy-duty shops, fleet maintenance | Automotive repair shops, dealerships |

Overview of Diesel Mechanic vs Auto Mechanic Roles

Diesel mechanics specialize in diagnosing, repairing, and maintaining diesel engines found in trucks, buses, and heavy machinery, focusing on high-torque engine systems and fuel injection technologies. Auto mechanics primarily work with gasoline-powered passenger vehicles, addressing issues related to emissions systems, ignition, and computerized engine management. The skill sets overlap but differ significantly in engine type expertise, diagnostic tools, and vehicle applications.

Key Responsibilities and Daily Tasks

Diesel mechanics specialize in diagnosing, repairing, and maintaining heavy-duty diesel engines found in trucks, buses, and industrial equipment, with key responsibilities including fuel system calibration, turbocharger repairs, and emission control adjustments. Auto mechanics focus on light vehicles such as cars and SUVs, performing tasks like engine tune-ups, brake repairs, and electrical system diagnostics. Both roles require expertise in engine performance analysis and troubleshooting, but diesel mechanics often handle larger, more complex machinery with higher torque and fuel efficiency standards.

Required Skills and Technical Expertise

Diesel mechanics specialize in the maintenance and repair of diesel engines, requiring deep knowledge of high-torque engine systems, fuel injection, and turbocharging components, whereas auto mechanics typically work on gasoline engines with expertise in electrical systems, engine diagnostics, and emission controls. Technical expertise for diesel mechanics includes proficiency in handling larger engine components, heavy-duty vehicle diagnostics, and familiarity with commercial vehicle regulations; auto mechanics need skills in computerized diagnostic tools, hybrid vehicle systems, and routine maintenance tasks. Both roles demand strong mechanical aptitude, problem-solving abilities, and continuous training to keep up with evolving automotive technologies.

Training, Certification, and Education Paths

Diesel mechanics typically undergo specialized training programs focusing on heavy-duty engines, often earning certifications like ASE Medium/Heavy Truck Certification, while auto mechanics usually complete more general automotive training with ASE certifications in passenger vehicles. Diesel mechanic education often requires hands-on experience with large vehicles like trucks and buses, emphasizing diesel engine diagnostics and repair, whereas auto mechanics focus on lighter vehicles and a broader range of systems including electronics and emissions. Both career paths prioritize technical school or community college programs, but diesel mechanics frequently pursue additional certifications specific to fuel injection systems and heavy machinery maintenance.

Work Environments and Typical Employers

Diesel mechanics commonly work in commercial truck repair shops, agricultural equipment dealerships, and heavy machinery maintenance facilities, where they handle large engines and complex diesel systems. Auto mechanics typically operate in retail auto service centers, dealerships specializing in passenger vehicles, and independent repair shops focused on gasoline engines and everyday automotive maintenance. Both professions may also find employment in government agencies, fleet services, and transportation companies, but the scale and specialization of the equipment they service differentiate their primary work environments.

Tools and Diagnostic Equipment Used

Diesel mechanics utilize heavy-duty tools such as pneumatic wrenches, diesel compression testers, and specialized diagnostic scanners for engines with complex fuel systems, while auto mechanics primarily work with handheld OBD-II scanners and standard toolkits for lighter vehicles. Diesel engines require advanced diagnostic equipment that can interpret electronic control module (ECM) data specific to diesel fuel injection and turbocharging systems. Auto mechanics employ versatile tools suitable for gasoline engines, exhaust systems, and electrical diagnostics, reflecting the broader range of lighter vehicle models they service.

Common Challenges in Each Field

Diesel mechanics frequently face challenges with complex engine diagnostics and emissions system regulations, requiring specialized tools and knowledge to repair heavy-duty engines. Auto mechanics encounter difficulties with diverse vehicle models and electronic systems, demanding constant updates on the latest automotive technology and software. Both fields must manage time-sensitive repairs and source reliable parts to ensure effective service and customer satisfaction.

Salary Ranges and Job Outlook

Diesel mechanics typically earn between $40,000 and $70,000 annually, with specialized skills in heavy-duty engines driving higher wages, while auto mechanics generally have a salary range of $35,000 to $60,000 depending on experience and certification levels. The job outlook for diesel mechanics is projected to grow by 6% over the next decade due to increasing demand in transportation and logistics sectors, whereas auto mechanic employment growth is estimated at around 4%, influenced by the rising complexity of vehicle technology and maintenance requirements. Both fields offer stable career opportunities, but diesel mechanics tend to command higher salaries and stronger demand in industrial and commercial markets.

Career Advancement Opportunities

Diesel mechanics often access specialized career advancement opportunities in heavy equipment and commercial transportation sectors, including supervisory roles and technical training certifications. Auto mechanics primarily advance through experience and certifications related to passenger vehicles, with potential for shop management or dealership positions. Both fields benefit from continuous education, but diesel mechanics typically engage in more niche, industry-specific skill development.

Choosing the Right Path: Factors to Consider

Choosing between a diesel mechanic and an auto mechanic career depends on factors such as vehicle specialization, engine type preference, and industry demand. Diesel mechanics often work with heavy-duty trucks and industrial equipment, requiring expertise in diesel engines and fuel systems, while auto mechanics focus on gasoline-powered cars, light trucks, and personal vehicles. Considering job market trends, training requirements, and personal interest in commercial versus consumer vehicles helps determine the most suitable path.

Diesel Mechanic vs Auto Mechanic Infographic

jobdiv.com

jobdiv.com