Preventive maintenance for pets involves routine health checks, vaccinations, and grooming to avoid illness and injury, promoting long-term wellness. Corrective repair addresses specific health issues or injuries after they occur, such as treating infections or mending wounds, which can be more costly and stressful. Prioritizing preventive care minimizes the need for corrective treatments, ensuring pets remain healthy and active.

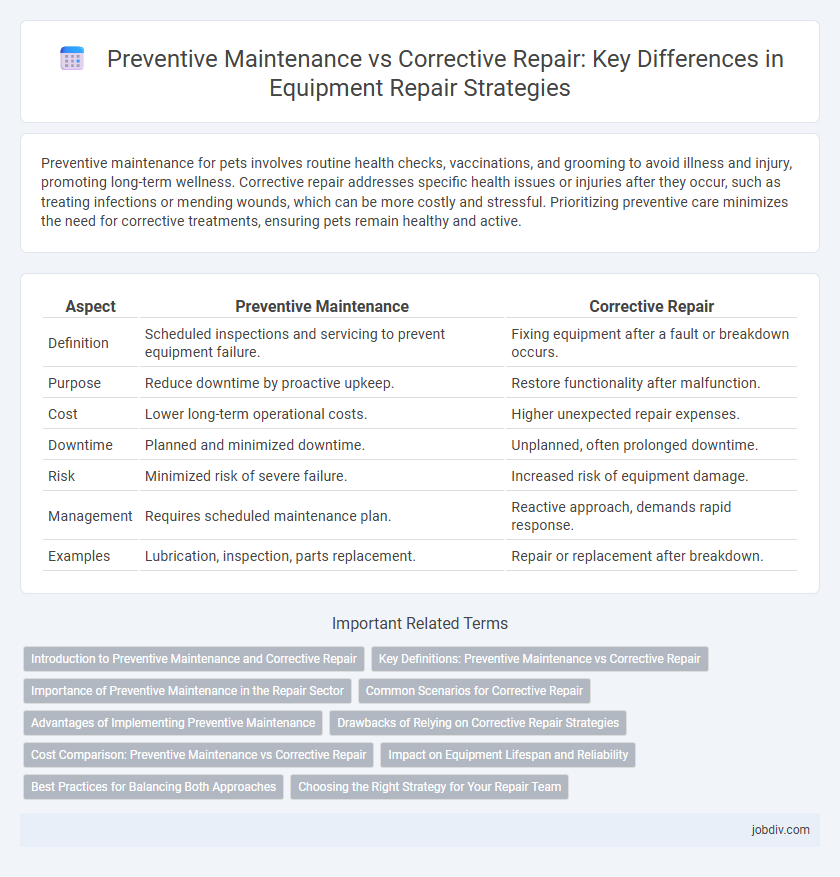

Table of Comparison

| Aspect | Preventive Maintenance | Corrective Repair |

|---|---|---|

| Definition | Scheduled inspections and servicing to prevent equipment failure. | Fixing equipment after a fault or breakdown occurs. |

| Purpose | Reduce downtime by proactive upkeep. | Restore functionality after malfunction. |

| Cost | Lower long-term operational costs. | Higher unexpected repair expenses. |

| Downtime | Planned and minimized downtime. | Unplanned, often prolonged downtime. |

| Risk | Minimized risk of severe failure. | Increased risk of equipment damage. |

| Management | Requires scheduled maintenance plan. | Reactive approach, demands rapid response. |

| Examples | Lubrication, inspection, parts replacement. | Repair or replacement after breakdown. |

Introduction to Preventive Maintenance and Corrective Repair

Preventive maintenance involves regular, scheduled inspections and servicing to detect and address potential issues before they lead to equipment failure, thereby minimizing downtime and extending asset lifespan. Corrective repair, in contrast, occurs after a malfunction or breakdown has happened, focusing on restoring equipment to operational condition as quickly as possible. Understanding the differences between preventive maintenance and corrective repair is crucial for optimizing operational efficiency and reducing overall maintenance costs.

Key Definitions: Preventive Maintenance vs Corrective Repair

Preventive maintenance involves scheduled inspections, servicing, and parts replacement to reduce the likelihood of equipment failure and extend asset lifespan. Corrective repair addresses unexpected breakdowns by diagnosing issues and restoring functionality after a fault occurs, often requiring immediate attention. Understanding these key definitions helps organizations balance maintenance strategies to optimize operational efficiency and minimize downtime.

Importance of Preventive Maintenance in the Repair Sector

Preventive maintenance significantly reduces downtime and repair costs by identifying and addressing potential equipment issues before they lead to failures, ensuring consistent operational efficiency. In the repair sector, regular inspections, lubrication, and component replacements prolong machinery lifespan and enhance safety standards. This proactive approach minimizes emergency repairs, improves asset reliability, and supports sustainable productivity in industrial and commercial environments.

Common Scenarios for Corrective Repair

Common scenarios for corrective repair include unexpected equipment failures, such as motor breakdowns or system malfunctions, that disrupt production processes and require immediate attention. Other frequent cases involve wear and tear damage that was not detected during routine inspections, resulting in sudden breakdowns or safety hazards. Corrective repair often addresses issues arising from improper use or external factors, necessitating swift intervention to minimize downtime and repair costs.

Advantages of Implementing Preventive Maintenance

Implementing preventive maintenance reduces equipment downtime by identifying and addressing potential issues before failures occur, leading to increased operational efficiency and extended asset lifespan. It lowers overall repair costs by minimizing emergency repairs and optimizing maintenance schedules based on equipment condition data. Enhanced safety and compliance with industry standards are additional benefits of a proactive maintenance approach, ensuring reliable and consistent production performance.

Drawbacks of Relying on Corrective Repair Strategies

Relying solely on corrective repair strategies often leads to increased downtime and higher overall maintenance costs due to unexpected equipment failures. This reactive approach can cause significant disruptions in production schedules and escalate the risk of severe damage to critical assets. In contrast, preventive maintenance minimizes these drawbacks by proactively identifying and addressing potential issues before they result in costly repairs.

Cost Comparison: Preventive Maintenance vs Corrective Repair

Preventive maintenance often reduces overall costs by minimizing unexpected equipment failures and extending asset lifespan, leading to lower repair expenses and downtime. Corrective repair typically incurs higher immediate costs due to emergency labor, expedited parts, and production losses. Investing in preventive maintenance decreases total cost of ownership by addressing issues before they escalate into expensive repairs.

Impact on Equipment Lifespan and Reliability

Preventive maintenance enhances equipment lifespan by addressing potential issues before failure occurs, reducing downtime and repair costs. Corrective repair, performed after equipment breakdown, can lead to increased wear and unexpected failures that compromise reliability. Prioritizing preventive strategies results in more consistent performance and extends the operational life of machinery.

Best Practices for Balancing Both Approaches

Balancing preventive maintenance and corrective repair involves implementing a strategic schedule that prioritizes routine inspections and timely servicing to reduce unexpected equipment failures. Leveraging data analytics and condition monitoring enhances decision-making by predicting potential breakdowns, enabling targeted preventive actions while minimizing unnecessary maintenance costs. Integrating both approaches through a comprehensive maintenance management system improves asset reliability and extends machinery lifespan by addressing issues proactively and efficiently responding to repairs when required.

Choosing the Right Strategy for Your Repair Team

Choosing the right strategy for your repair team depends on balancing Preventive Maintenance and Corrective Repair to optimize equipment uptime and cost efficiency. Preventive Maintenance involves scheduled inspections and servicing to prevent failures, reducing unexpected downtime and extending asset lifespan. Corrective Repair addresses issues after a breakdown occurs, often leading to higher immediate costs but is sometimes necessary for unexpected or complex failures.

Preventive Maintenance vs Corrective Repair Infographic

jobdiv.com

jobdiv.com