Workshop fitters benefit from a controlled environment with specialized tools and equipment, enabling precise and thorough pet repair services. Mobile fitters offer the convenience of on-site repairs, saving pet owners time and minimizing stress for pets by avoiding transportation. Choosing between the two depends on the complexity of the repair and the pet's comfort during the service.

Table of Comparison

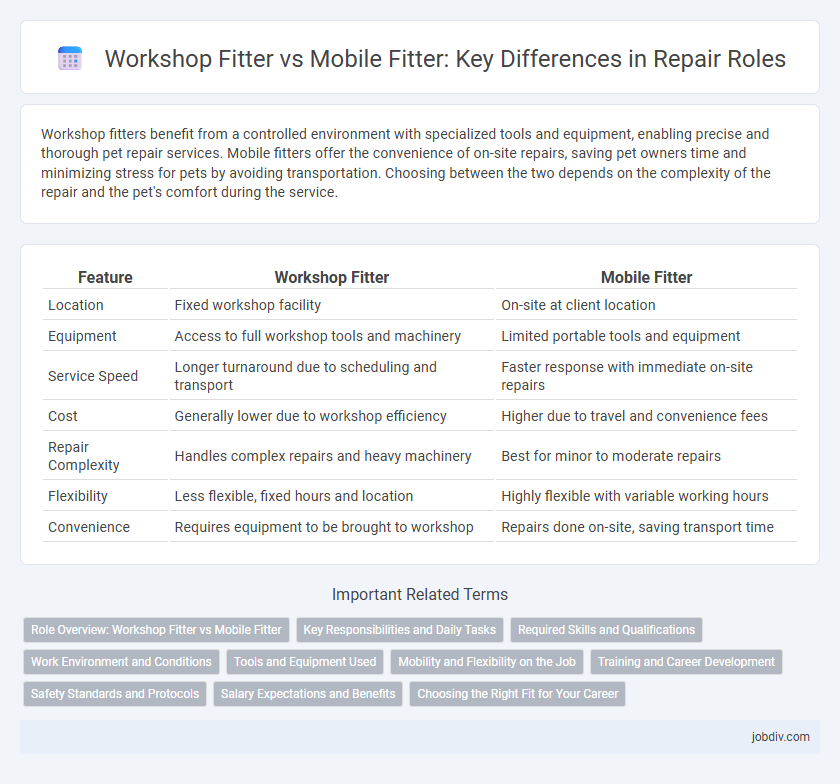

| Feature | Workshop Fitter | Mobile Fitter |

|---|---|---|

| Location | Fixed workshop facility | On-site at client location |

| Equipment | Access to full workshop tools and machinery | Limited portable tools and equipment |

| Service Speed | Longer turnaround due to scheduling and transport | Faster response with immediate on-site repairs |

| Cost | Generally lower due to workshop efficiency | Higher due to travel and convenience fees |

| Repair Complexity | Handles complex repairs and heavy machinery | Best for minor to moderate repairs |

| Flexibility | Less flexible, fixed hours and location | Highly flexible with variable working hours |

| Convenience | Requires equipment to be brought to workshop | Repairs done on-site, saving transport time |

Role Overview: Workshop Fitter vs Mobile Fitter

Workshop fitters specialize in assembling, maintaining, and repairing components within a controlled, indoor environment equipped with specialized tools and machinery, ensuring precision and high-quality workmanship. Mobile fitters perform similar tasks but operate on-site, traveling to various locations to conduct repairs and installations directly at the client's facility, requiring adaptability and problem-solving skills in diverse conditions. Both roles demand expertise in mechanical systems, but the key difference lies in the controlled workshop setting versus the dynamic, on-site working environment.

Key Responsibilities and Daily Tasks

Workshop fitters primarily handle equipment repairs and maintenance in a controlled environment, focusing on precision fitting, assembly, and calibration of machinery components. Mobile fitters perform on-site repairs and troubleshooting, requiring adaptability to various locations and conditions while managing urgent breakdowns and preventive maintenance. Both roles demand strong mechanical skills, but workshop fitters emphasize detailed, high-accuracy tasks, whereas mobile fitters prioritize versatility and rapid response.

Required Skills and Qualifications

Workshop fitters require strong technical skills in machining, welding, and equipment assembly, along with formal certifications in mechanical or industrial trades. Mobile fitters must have advanced troubleshooting abilities, adaptability to different environments, and proficiency in on-site repairs, often necessitating a broader range of practical experience and safety training. Both roles demand comprehensive knowledge of mechanical systems, but mobile fitters prioritize mobility and problem-solving under variable conditions.

Work Environment and Conditions

Workshop fitters operate in controlled environments equipped with specialized tools and machinery, ensuring precision and safety during repairs and fabrications. Mobile fitters face variable work conditions on-site, often dealing with unpredictable weather, limited equipment, and space constraints that require adaptability and quick problem-solving. The workshop setting favors quality control and efficiency, while mobile fitting demands flexibility and resilience to maintain high repair standards outside traditional facilities.

Tools and Equipment Used

Workshop fitters rely on a wide range of stationary tools and heavy-duty equipment such as hydraulic presses, welding machines, and precision measurement instruments to perform repairs in a controlled environment. Mobile fitters utilize portable tools including cordless drills, impact wrenches, and compact welding units designed for on-site repairs where access to power sources and large equipment is limited. The choice of tools significantly impacts efficiency, with workshop fitters benefiting from higher accuracy and power, while mobile fitters prioritize versatility and mobility.

Mobility and Flexibility on the Job

Workshop fitters operate within a fixed location, providing specialized repairs and maintenance with access to comprehensive tools and equipment. Mobile fitters travel directly to job sites, offering greater flexibility and on-site troubleshooting but often with limited tool availability. Mobility enables mobile fitters to respond swiftly to urgent repairs across multiple locations, while workshop fitters benefit from a controlled environment for complex and precision tasks.

Training and Career Development

Workshop fitters typically undergo formal apprenticeships and technical training in controlled environments, gaining hands-on experience with a wide range of tools and machinery that enhance their precision and technical skills. Mobile fitters require versatile training focused on adaptability and problem-solving, often involving on-site equipment repair and diagnostics in diverse and challenging conditions. Career development for workshop fitters often leads to specialized roles or supervisory positions, while mobile fitters may advance into consultancy or technical support roles due to their extensive field experience.

Safety Standards and Protocols

Workshop fitters operate within controlled environments that strictly adhere to established safety standards and protocols, ensuring consistent use of personal protective equipment (PPE) and systematic hazard controls. Mobile fitters face variable conditions requiring adaptable safety measures tailored to onsite risks, often relying on comprehensive risk assessments and versatile safety gear to maintain compliance. Both roles prioritize injury prevention, but workshop fitters benefit from stable safety infrastructure, whereas mobile fitters emphasize situational awareness and flexible safety practices.

Salary Expectations and Benefits

Workshop fitters typically earn a stable salary ranging from $30,000 to $45,000 annually, with benefits including fixed working hours, paid leave, and access to on-site tools and facilities. Mobile fitters can command higher wages, often between $40,000 and $60,000 per year, supplemented by travel allowances, overtime pay, and the flexibility to work across multiple job sites. Companies hiring mobile fitters may also offer performance bonuses and reimbursement for travel expenses, reflecting the specialized skills and mobility required for the role.

Choosing the Right Fit for Your Career

Workshop fitters specialize in equipment repair within a controlled environment, offering access to advanced tools and stable work conditions that facilitate precision and efficiency. Mobile fitters provide on-site repair services, requiring adaptability and problem-solving skills to address diverse mechanical issues across various locations. Choosing the right career path depends on preferences for work environment, travel frequency, and specialization in either stationary or field repairs.

Workshop Fitter vs Mobile Fitter Infographic

jobdiv.com

jobdiv.com