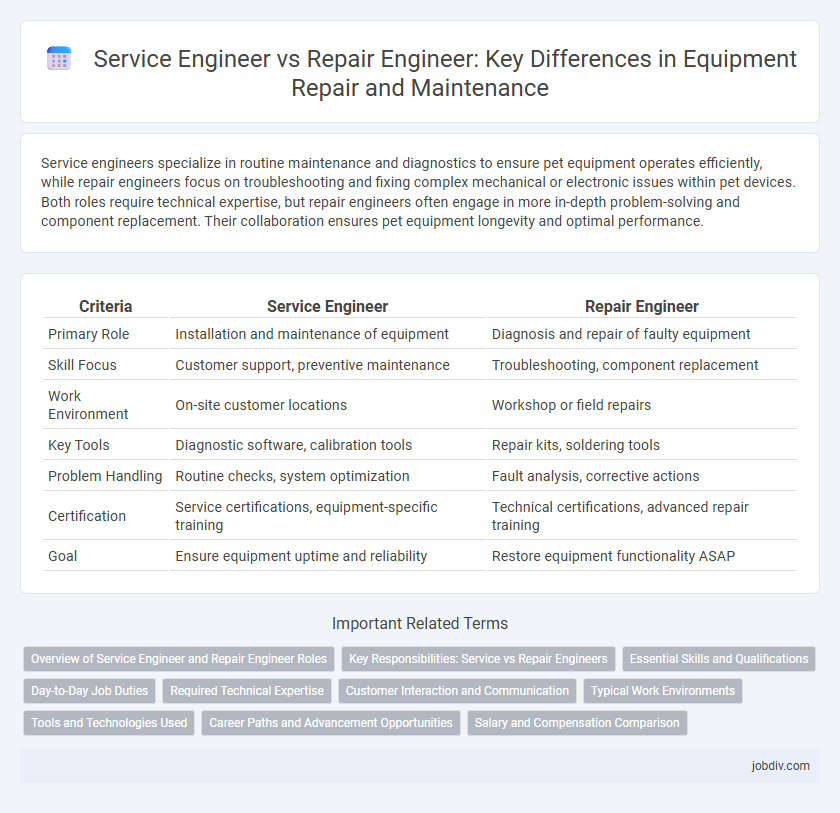

Service engineers specialize in routine maintenance and diagnostics to ensure pet equipment operates efficiently, while repair engineers focus on troubleshooting and fixing complex mechanical or electronic issues within pet devices. Both roles require technical expertise, but repair engineers often engage in more in-depth problem-solving and component replacement. Their collaboration ensures pet equipment longevity and optimal performance.

Table of Comparison

| Criteria | Service Engineer | Repair Engineer |

|---|---|---|

| Primary Role | Installation and maintenance of equipment | Diagnosis and repair of faulty equipment |

| Skill Focus | Customer support, preventive maintenance | Troubleshooting, component replacement |

| Work Environment | On-site customer locations | Workshop or field repairs |

| Key Tools | Diagnostic software, calibration tools | Repair kits, soldering tools |

| Problem Handling | Routine checks, system optimization | Fault analysis, corrective actions |

| Certification | Service certifications, equipment-specific training | Technical certifications, advanced repair training |

| Goal | Ensure equipment uptime and reliability | Restore equipment functionality ASAP |

Overview of Service Engineer and Repair Engineer Roles

Service engineers specialize in the installation, maintenance, and optimization of equipment, ensuring operational efficiency and minimizing downtime. Repair engineers focus primarily on diagnosing faults, troubleshooting issues, and executing repairs to restore functionality. Both roles require technical expertise, but service engineers emphasize preventive care while repair engineers address corrective actions.

Key Responsibilities: Service vs Repair Engineers

Service engineers specialize in maintaining, installing, and troubleshooting equipment to ensure optimal performance and prevent breakdowns. Repair engineers focus on diagnosing faults, disassembling machinery, and executing technical repairs to restore functionality after equipment failure. Both roles require strong technical knowledge, but service engineers emphasize preventive maintenance, while repair engineers concentrate on corrective actions.

Essential Skills and Qualifications

Service engineers require strong diagnostic abilities, customer communication skills, and proficiency in preventive maintenance to ensure optimal equipment functionality. Repair engineers focus on expertise in troubleshooting, hands-on repairing, and knowledge of mechanical or electronic systems to restore faulty machinery. Both roles demand technical certifications, problem-solving aptitude, and familiarity with industry-specific standards and safety protocols.

Day-to-Day Job Duties

Service engineers primarily conduct routine maintenance, installation, and system diagnostics to ensure optimal equipment performance. Repair engineers focus on troubleshooting, identifying faults, and executing corrective repairs to restore functionality quickly. Both roles require technical expertise but differ in their daily emphasis on preventive care versus reactive problem-solving.

Required Technical Expertise

Service Engineers specialize in preventive maintenance, diagnostics, and system optimization, requiring expertise in troubleshooting and routine servicing of equipment. Repair Engineers focus on fault analysis and component replacement, demanding in-depth knowledge of complex repair techniques and restoration processes. Mastery in specific technical domains, such as electronics, mechanical systems, or software, differentiates the required technical expertise between these roles.

Customer Interaction and Communication

Service engineers excel in customer interaction by diagnosing issues on-site and providing real-time updates, ensuring clear communication throughout the maintenance process. Repair engineers focus primarily on technical problem-solving and equipment restoration, often working behind the scenes with limited direct customer engagement. Effective communication skills are crucial for service engineers to translate complex technical details into understandable information, enhancing customer satisfaction and trust.

Typical Work Environments

Service engineers typically work in field settings, visiting client sites to install, maintain, and troubleshoot equipment, often in industries such as telecommunications, healthcare, and manufacturing. Repair engineers usually operate within controlled environments like workshops or factories, focusing on diagnosing and fixing hardware issues in electronic devices, machinery, or automotive components. Both roles demand technical expertise, but the service engineer's work environment requires mobility and customer interaction, while the repair engineer relies on specialized tools and a stable workspace.

Tools and Technologies Used

Service Engineers predominantly utilize diagnostic software and handheld devices for system analysis and preventive maintenance, emphasizing calibration tools and network testing equipment tailored to specific industry standards. Repair Engineers focus on advanced soldering stations, power tools, and specialized replacement parts, leveraging repair manuals and fault isolation devices to restore equipment functionality. Both roles require proficiency in computerized maintenance management systems (CMMS) and multimeters, but Repair Engineers engage more extensively with hardware restoration technologies and component-level troubleshooting.

Career Paths and Advancement Opportunities

Service Engineers primarily focus on installation, maintenance, and troubleshooting of equipment, developing strong customer interaction skills that open pathways to technical management and client support roles. Repair Engineers specialize in diagnosing and fixing complex mechanical or electronic failures, gaining expertise that can lead to senior technical positions or roles in quality assurance and product development. Career advancement for both paths often involves certifications, specialized training, and transitioning into leadership or consultancy within the engineering sector.

Salary and Compensation Comparison

Service engineers typically earn a median salary ranging from $60,000 to $80,000 annually, reflecting their role in routine maintenance and technical support, while repair engineers command higher compensation between $70,000 and $90,000 due to specialized skills in fault diagnosis and complex machinery repair. Compensation packages for repair engineers often include performance bonuses and overtime pay, emphasizing their critical role in minimizing downtime, whereas service engineers may receive supplemental benefits like travel allowances and technical training stipends. Regional demand, industry specialization, and certification levels significantly influence salary variations, with repair engineers in sectors like aerospace or heavy machinery generally achieving top-tier earnings.

Service Engineer vs Repair Engineer Infographic

jobdiv.com

jobdiv.com