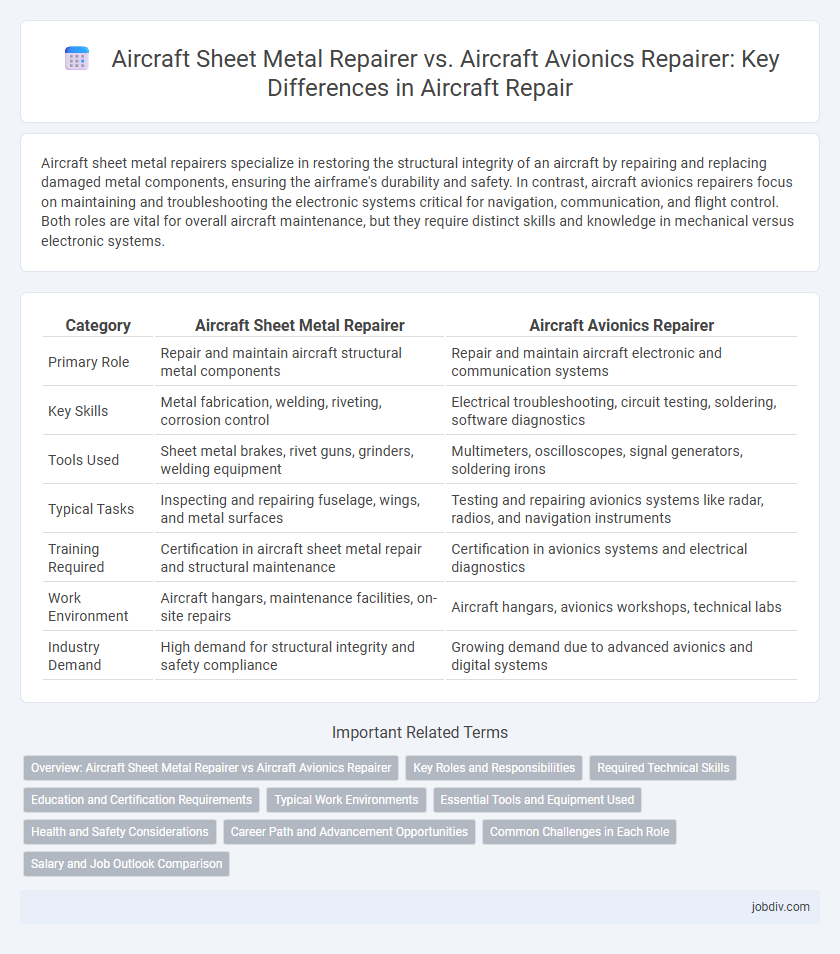

Aircraft sheet metal repairers specialize in restoring the structural integrity of an aircraft by repairing and replacing damaged metal components, ensuring the airframe's durability and safety. In contrast, aircraft avionics repairers focus on maintaining and troubleshooting the electronic systems critical for navigation, communication, and flight control. Both roles are vital for overall aircraft maintenance, but they require distinct skills and knowledge in mechanical versus electronic systems.

Table of Comparison

| Category | Aircraft Sheet Metal Repairer | Aircraft Avionics Repairer |

|---|---|---|

| Primary Role | Repair and maintain aircraft structural metal components | Repair and maintain aircraft electronic and communication systems |

| Key Skills | Metal fabrication, welding, riveting, corrosion control | Electrical troubleshooting, circuit testing, soldering, software diagnostics |

| Tools Used | Sheet metal brakes, rivet guns, grinders, welding equipment | Multimeters, oscilloscopes, signal generators, soldering irons |

| Typical Tasks | Inspecting and repairing fuselage, wings, and metal surfaces | Testing and repairing avionics systems like radar, radios, and navigation instruments |

| Training Required | Certification in aircraft sheet metal repair and structural maintenance | Certification in avionics systems and electrical diagnostics |

| Work Environment | Aircraft hangars, maintenance facilities, on-site repairs | Aircraft hangars, avionics workshops, technical labs |

| Industry Demand | High demand for structural integrity and safety compliance | Growing demand due to advanced avionics and digital systems |

Overview: Aircraft Sheet Metal Repairer vs Aircraft Avionics Repairer

Aircraft Sheet Metal Repairers specialize in inspecting, repairing, and replacing metal components of an aircraft's structure, including fuselage, wings, and control surfaces, using techniques like welding, riveting, and metal shaping. Aircraft Avionics Repairers focus on the maintenance and troubleshooting of electronic systems such as navigation, communication, radar, and flight control instruments, ensuring all avionics equipment meets stringent safety and operational standards. Both roles require specialized technical training and certification but differ fundamentally in their areas of expertise--structural integrity versus electronic system functionality.

Key Roles and Responsibilities

Aircraft Sheet Metal Repairers specialize in inspecting, cutting, shaping, and assembling metal components to maintain the structural integrity of aircraft, ensuring aircraft surfaces and frames meet safety standards. Aircraft Avionics Repairers focus on diagnosing, repairing, and maintaining electronic systems such as navigation, communication, and radar equipment critical for aircraft operation. While both roles require technical expertise, Sheet Metal Repairers handle physical airframe repairs, and Avionics Repairers manage sophisticated electronic instrumentation and system functionality.

Required Technical Skills

Aircraft Sheet Metal Repairers require expertise in fabricating, shaping, and installing metal components using tools such as grinders, drills, and welders, with a strong understanding of aircraft structural integrity and corrosion control. In contrast, Aircraft Avionics Repairers must possess advanced skills in troubleshooting, testing, and repairing electronic systems, including communication, navigation, and radar equipment, utilizing diagnostic software and multimeters. Both roles demand proficiency in interpreting technical manuals and blueprints, but Sheet Metal Repairers focus more on mechanical and material knowledge while Avionics Repairers emphasize electronic circuitry and software systems.

Education and Certification Requirements

Aircraft Sheet Metal Repairers typically require a high school diploma or GED, followed by specialized training through FAA-approved aviation maintenance technician schools focusing on sheet metal fabrication and structural repairs; certification includes obtaining an Airframe and Powerplant (A&P) license from the Federal Aviation Administration. Aircraft Avionics Repairers, on the other hand, often need more advanced education in electronics or avionics technology, such as an associate degree or technical certification, with FAA certification in avionics systems maintenance and repair being essential for compliance and employment. Both roles demand ongoing training and recertification to stay current with evolving aviation safety standards and technological advancements.

Typical Work Environments

Aircraft sheet metal repairers primarily work in hangars, maintenance shops, and manufacturing facilities where they handle structural repairs on airframes, often exposed to large metal parts and heavy machinery. Aircraft avionics repairers typically operate in specialized avionics labs, maintenance bays, or aircraft interiors where they diagnose and fix electronic systems, requiring precision tools and controlled environments to prevent static damage. Both professions demand adherence to strict safety protocols, but the physical setting and equipment used differ significantly due to the nature of the repairs conducted.

Essential Tools and Equipment Used

Aircraft Sheet Metal Repairers primarily use rivet guns, metal shears, pneumatic drills, and torque wrenches to cut, shape, and fasten metal components in airframes. Aircraft Avionics Repairers rely on oscilloscopes, multimeters, soldering irons, and signal generators to diagnose, troubleshoot, and repair electronic systems. Both professions require precision tools tailored to their specialized tasks, emphasizing safety and reliability in aircraft maintenance.

Health and Safety Considerations

Aircraft Sheet Metal Repairers face significant health and safety risks related to sharp tools, metal dust, and exposure to hazardous chemicals used in metal treatments, necessitating protective gear such as gloves, goggles, and respirators. Aircraft Avionics Repairers work with sensitive electronic components and wiring, where electrical hazards, soldering fumes, and ergonomic strain require stringent precautions like insulated gloves, proper ventilation, and anti-static equipment. Both roles demand adherence to strict safety protocols to prevent accidents and long-term health issues in aircraft maintenance environments.

Career Path and Advancement Opportunities

Aircraft Sheet Metal Repairers specialize in structural maintenance, working with aluminum and composite materials to ensure airframe integrity, offering career advancement through certifications such as FAA Airframe & Powerplant (A&P) licenses leading to senior roles in maintenance supervision. Aircraft Avionics Repairers focus on complex electronic systems, including navigation, communication, and radar, with opportunities for advancement by acquiring specialized avionics certifications or transitioning into avionics systems engineering and management positions. Both career paths offer progression from entry-level technician roles to specialized expert or managerial positions within aerospace maintenance organizations.

Common Challenges in Each Role

Aircraft Sheet Metal Repairers often face challenges such as corrosion control, fatigue cracking, and precise metal shaping to ensure structural integrity. Aircraft Avionics Repairers commonly encounter difficulties with diagnosing complex electronic malfunctions, software integration issues, and maintaining compliance with rapidly evolving avionics technology standards. Both roles require meticulous attention to detail and adherence to stringent aviation safety regulations to prevent system failures and ensure airworthiness.

Salary and Job Outlook Comparison

Aircraft sheet metal repairers earn an average annual salary of approximately $58,000, with job demand expected to grow 5% through 2030 due to increased aircraft maintenance needs. Aircraft avionics repairers typically command higher salaries averaging around $75,000 per year, driven by the complexity and technical expertise required for advanced avionics systems, with job opportunities projected to increase 7% in the same period. Both occupations offer strong job security, but avionics repairers benefit from higher compensation and slightly stronger employment growth thanks to evolving aircraft technology.

Aircraft Sheet Metal Repairer vs Aircraft Avionics Repairer Infographic

jobdiv.com

jobdiv.com