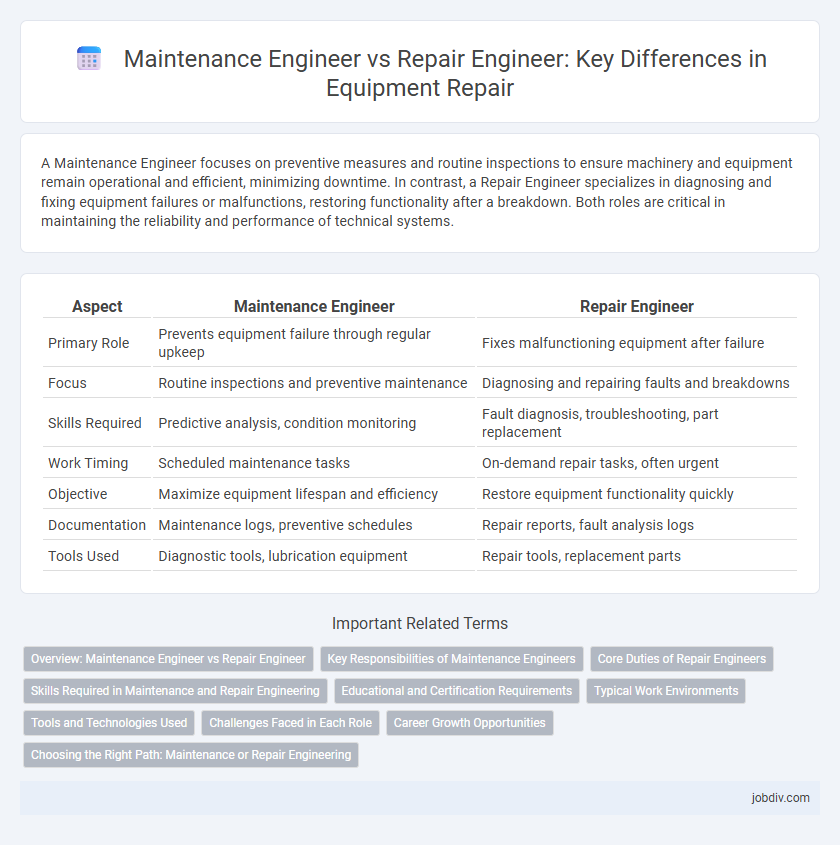

A Maintenance Engineer focuses on preventive measures and routine inspections to ensure machinery and equipment remain operational and efficient, minimizing downtime. In contrast, a Repair Engineer specializes in diagnosing and fixing equipment failures or malfunctions, restoring functionality after a breakdown. Both roles are critical in maintaining the reliability and performance of technical systems.

Table of Comparison

| Aspect | Maintenance Engineer | Repair Engineer |

|---|---|---|

| Primary Role | Prevents equipment failure through regular upkeep | Fixes malfunctioning equipment after failure |

| Focus | Routine inspections and preventive maintenance | Diagnosing and repairing faults and breakdowns |

| Skills Required | Predictive analysis, condition monitoring | Fault diagnosis, troubleshooting, part replacement |

| Work Timing | Scheduled maintenance tasks | On-demand repair tasks, often urgent |

| Objective | Maximize equipment lifespan and efficiency | Restore equipment functionality quickly |

| Documentation | Maintenance logs, preventive schedules | Repair reports, fault analysis logs |

| Tools Used | Diagnostic tools, lubrication equipment | Repair tools, replacement parts |

Overview: Maintenance Engineer vs Repair Engineer

Maintenance Engineers focus on preventive measures, system diagnostics, and routine servicing to ensure optimal equipment performance and minimize downtime. Repair Engineers specialize in troubleshooting, fault analysis, and rectifying mechanical or electrical malfunctions to restore equipment functionality. Both roles are critical in industrial settings, with Maintenance Engineers prioritizing longevity and Repair Engineers emphasizing swift resolution of breakdowns.

Key Responsibilities of Maintenance Engineers

Maintenance Engineers focus on ensuring the continuous operation of machinery through routine inspections, preventative maintenance, and system optimization to minimize downtime. They analyze equipment performance data and implement maintenance schedules designed to extend asset life and improve reliability. Key responsibilities include troubleshooting mechanical failures, coordinating with production teams, and updating maintenance documentation to comply with safety and industry standards.

Core Duties of Repair Engineers

Repair Engineers specialize in diagnosing, troubleshooting, and restoring faulty machinery to optimal working condition, ensuring minimal downtime and operational efficiency. Their core duties include performing detailed inspections, replacing or repairing defective components, and conducting rigorous testing to verify repair effectiveness. They collaborate closely with maintenance teams but focus primarily on corrective actions rather than routine maintenance tasks.

Skills Required in Maintenance and Repair Engineering

Maintenance engineers require strong skills in preventive maintenance, equipment diagnostics, and system optimization to ensure operational efficiency and minimize downtime. Repair engineers excel in fault analysis, troubleshooting, and hands-on technical repair of machinery and electrical systems, emphasizing quick restoration of functionality. Proficiency in mechanical, electrical, and software systems, along with problem-solving and analytical abilities, is crucial for both roles to effectively support industrial operations.

Educational and Certification Requirements

Maintenance engineers typically require a bachelor's degree in mechanical, electrical, or industrial engineering alongside certifications such as Certified Maintenance & Reliability Professional (CMRP) or OSHA safety training. Repair engineers often hold similar engineering degrees but emphasize specialized certifications in troubleshooting and repair techniques, including vendor-specific credentials like Cisco Certified Network Associate (CCNA) or automotive ASE certifications. Both roles demand continuous professional development to stay current with evolving technologies and industry standards.

Typical Work Environments

Maintenance engineers typically work in industrial plants, manufacturing facilities, and large-scale production environments where they focus on preventive maintenance and system optimization. Repair engineers are often found in field service roles, workshops, or customer sites, specializing in troubleshooting and fixing equipment breakdowns. Both roles require hands-on technical skills but differ in their primary work settings and operational focus.

Tools and Technologies Used

Maintenance engineers utilize predictive maintenance tools such as vibration analyzers, thermal imaging cameras, and computerized maintenance management systems (CMMS) to monitor equipment health and prevent failures. Repair engineers rely on diagnostic devices, handheld multimeters, and specialized repair software to troubleshoot and restore malfunctioning machinery efficiently. Both roles integrate advanced technologies like IoT sensors and augmented reality for enhanced precision and faster problem resolution.

Challenges Faced in Each Role

Maintenance engineers face challenges such as predicting equipment failures, scheduling preventive maintenance without disrupting operations, and managing resource allocation for routine upkeep. Repair engineers encounter difficulties diagnosing unexpected breakdowns quickly, procuring the right spare parts under time constraints, and working under pressure to restore functionality promptly. Both roles require strong problem-solving skills, but maintenance engineers emphasize long-term system reliability while repair engineers focus on immediate issue resolution.

Career Growth Opportunities

Maintenance Engineers focus on preventive strategies, optimizing equipment longevity and minimizing breakdowns, which often leads to managerial roles in asset management and operational planning. Repair Engineers specialize in diagnosing and fixing malfunctions, developing expertise that can lead to advanced technical positions or supervisory roles in emergency response teams. Both career paths offer progression, but Maintenance Engineers typically experience broader growth opportunities due to their proactive involvement in system optimization and continuous improvement initiatives.

Choosing the Right Path: Maintenance or Repair Engineering

Maintenance engineers specialize in proactive system upkeep, using predictive analytics and routine inspections to prevent equipment failures and optimize operational efficiency. Repair engineers focus on diagnosing and resolving mechanical or electrical faults, rapidly restoring functionality to minimize downtime and production losses. Choosing between maintenance and repair engineering depends on whether one prefers strategic preventative care or dynamic problem-solving in reactive scenarios.

Maintenance Engineer vs Repair Engineer Infographic

jobdiv.com

jobdiv.com