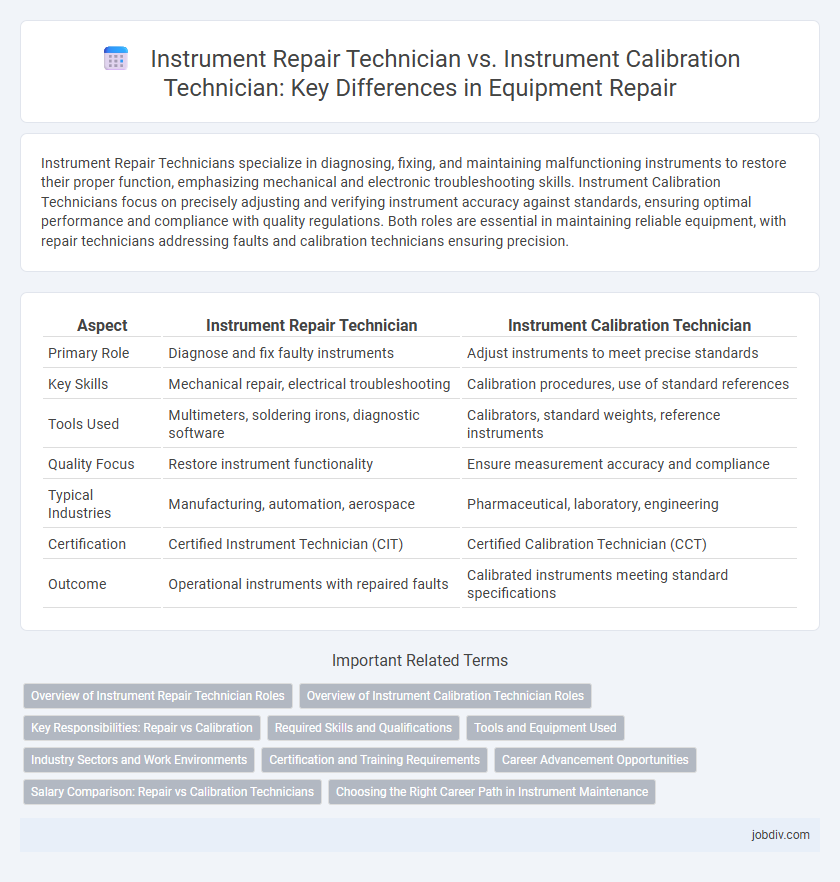

Instrument Repair Technicians specialize in diagnosing, fixing, and maintaining malfunctioning instruments to restore their proper function, emphasizing mechanical and electronic troubleshooting skills. Instrument Calibration Technicians focus on precisely adjusting and verifying instrument accuracy against standards, ensuring optimal performance and compliance with quality regulations. Both roles are essential in maintaining reliable equipment, with repair technicians addressing faults and calibration technicians ensuring precision.

Table of Comparison

| Aspect | Instrument Repair Technician | Instrument Calibration Technician |

|---|---|---|

| Primary Role | Diagnose and fix faulty instruments | Adjust instruments to meet precise standards |

| Key Skills | Mechanical repair, electrical troubleshooting | Calibration procedures, use of standard references |

| Tools Used | Multimeters, soldering irons, diagnostic software | Calibrators, standard weights, reference instruments |

| Quality Focus | Restore instrument functionality | Ensure measurement accuracy and compliance |

| Typical Industries | Manufacturing, automation, aerospace | Pharmaceutical, laboratory, engineering |

| Certification | Certified Instrument Technician (CIT) | Certified Calibration Technician (CCT) |

| Outcome | Operational instruments with repaired faults | Calibrated instruments meeting standard specifications |

Overview of Instrument Repair Technician Roles

Instrument Repair Technicians specialize in diagnosing, troubleshooting, and repairing mechanical and electronic instruments to ensure optimal functionality. Their responsibilities include replacing faulty components, performing routine maintenance, and restoring devices to factory specifications. Expertise in interpreting technical manuals and using diagnostic tools is essential for maintaining precise instrument performance.

Overview of Instrument Calibration Technician Roles

Instrument Calibration Technicians specialize in precisely adjusting and verifying the accuracy of measuring instruments to ensure optimal performance and compliance with industry standards. Their responsibilities include performing routine calibrations, troubleshooting discrepancies, and maintaining detailed calibration records in accordance with quality control protocols. These technicians play a critical role in industries such as manufacturing, pharmaceuticals, and aerospace, where instrument precision directly impacts product quality and safety.

Key Responsibilities: Repair vs Calibration

Instrument Repair Technicians specialize in diagnosing, troubleshooting, and fixing malfunctioning equipment, ensuring all components operate efficiently and safely. Instrument Calibration Technicians focus on adjusting, testing, and verifying instruments to meet precise measurement standards and regulatory requirements. Repair emphasizes restoring functionality, while calibration prioritizes accuracy and compliance with technical specifications.

Required Skills and Qualifications

Instrument Repair Technicians require expertise in diagnosing and resolving mechanical, electrical, and software malfunctions, along with proficiency in using diagnostic tools and interpreting technical manuals. Instrument Calibration Technicians must possess strong knowledge of calibration standards, measurement techniques, and precision instruments, ensuring accurate adjustment and documentation compliance. Both roles demand technical certifications such as IPC or NIST guidelines familiarity, but calibration technicians often require advanced skills in metrology and quality assurance protocols.

Tools and Equipment Used

Instrument Repair Technicians primarily use diagnostic tools such as multimeters, oscilloscopes, and soldering irons to troubleshoot and fix faulty electronic components. Instrument Calibration Technicians rely on precision calibration equipment like signal generators, standard references, and calibration software to ensure instruments meet exact measurement standards. Both roles require specialized toolkits, but Repair Technicians focus on restoration tools while Calibration Technicians emphasize measurement accuracy instruments.

Industry Sectors and Work Environments

Instrument Repair Technicians primarily operate in manufacturing plants, power generation facilities, and industrial maintenance environments, focusing on diagnosing and fixing malfunctioning equipment. Instrument Calibration Technicians are commonly employed in pharmaceutical, aerospace, and laboratory settings where precise measurement and regulatory compliance are critical. Both roles are essential in industries like oil and gas, chemical processing, and automation, but calibration specialists emphasize accuracy and standards adherence while repair technicians concentrate on functional restoration.

Certification and Training Requirements

Instrument Repair Technicians typically require certification such as IPC (Instrument and Process Control) or specialized manufacturer training to handle complex electrical and mechanical repairs, emphasizing hands-on technical skills. Instrument Calibration Technicians focus on precise measurement verification and usually hold certifications from organizations like NIST or ISO 17025-compliant training programs, highlighting expertise in calibration standards and metrology. Both roles demand continuous education and proficiency in industry-specific tools but differ primarily in their certification governing repair procedures versus measurement accuracy.

Career Advancement Opportunities

Instrument Repair Technicians gain hands-on experience troubleshooting and restoring complex systems, making them valuable for advanced diagnostic roles. Instrument Calibration Technicians develop precision measurement skills that lead to expertise in quality assurance and regulatory compliance positions. Both career paths offer upward mobility, with Repair Technicians often moving into technical specialist roles and Calibration Technicians advancing into process optimization and lab management.

Salary Comparison: Repair vs Calibration Technicians

Instrument Repair Technicians typically earn a median annual salary ranging from $45,000 to $60,000, reflecting their expertise in diagnosing and fixing mechanical and electronic instrument faults. In contrast, Instrument Calibration Technicians often command higher wages between $55,000 and $70,000 due to specialized skills in precision measurement and equipment standardization. Salary disparities highlight the premium placed on calibration accuracy and regulatory compliance in industries such as manufacturing, aerospace, and pharmaceuticals.

Choosing the Right Career Path in Instrument Maintenance

Instrument Repair Technicians specialize in diagnosing and fixing hardware malfunctions, ensuring the physical components of instruments function correctly, while Instrument Calibration Technicians focus on adjusting and calibrating devices to maintain measurement accuracy and compliance with industry standards. Selecting the right career path depends on interests in hands-on mechanical troubleshooting or precision measurement and quality control processes within sectors like manufacturing, pharmaceuticals, or environmental monitoring. Both roles require technical expertise and offer opportunities for specialization in instrument maintenance, emphasizing the importance of aligning career choices with individual skills and industry demand.

Instrument Repair Technician vs Instrument Calibration Technician Infographic

jobdiv.com

jobdiv.com