Reactive repair addresses pet health issues only after symptoms appear, often resulting in more extensive and costly treatments. Proactive repair emphasizes regular check-ups and preventive care to identify and resolve minor problems before they escalate. Choosing proactive repair improves pet well-being and reduces the risk of severe injuries or illnesses.

Table of Comparison

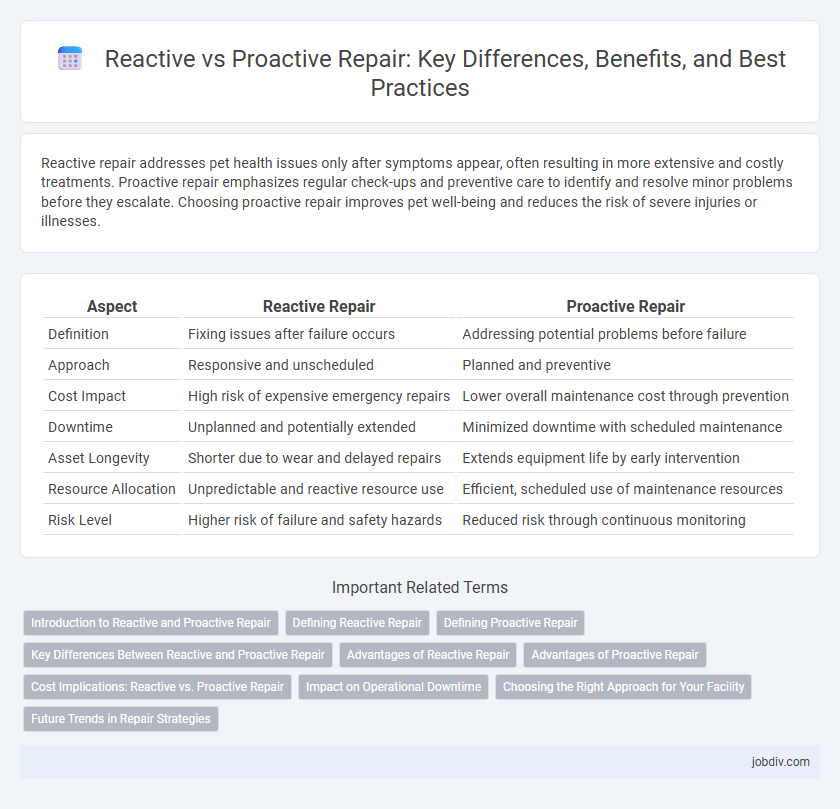

| Aspect | Reactive Repair | Proactive Repair |

|---|---|---|

| Definition | Fixing issues after failure occurs | Addressing potential problems before failure |

| Approach | Responsive and unscheduled | Planned and preventive |

| Cost Impact | High risk of expensive emergency repairs | Lower overall maintenance cost through prevention |

| Downtime | Unplanned and potentially extended | Minimized downtime with scheduled maintenance |

| Asset Longevity | Shorter due to wear and delayed repairs | Extends equipment life by early intervention |

| Resource Allocation | Unpredictable and reactive resource use | Efficient, scheduled use of maintenance resources |

| Risk Level | Higher risk of failure and safety hazards | Reduced risk through continuous monitoring |

Introduction to Reactive and Proactive Repair

Reactive repair involves fixing equipment or systems only after a failure has occurred, prioritizing immediate restoration of functionality. Proactive repair emphasizes regular maintenance and early detection to prevent breakdowns, reducing downtime and prolonging asset lifespan. Both strategies impact operational efficiency, with proactive repair fostering sustained productivity and reactive repair addressing urgent issues.

Defining Reactive Repair

Reactive repair involves addressing equipment or system failures after they occur, often leading to unplanned downtime and higher costs due to emergency fixes. This approach focuses on fixing problems only when they disrupt operations, without prior maintenance or inspection. Reactive repair contrasts with proactive repair strategies that emphasize preventive measures and condition-based monitoring to avoid unexpected breakdowns.

Defining Proactive Repair

Proactive repair involves regularly scheduled maintenance and early detection techniques to identify potential equipment failures before they occur, minimizing unplanned downtime. Techniques such as condition monitoring, predictive analytics, and routine inspections enable organizations to address issues at their inception, reducing overall repair costs. This approach contrasts with reactive repair, which responds only after a malfunction or breakdown has happened, often leading to more extensive damage and operational disruptions.

Key Differences Between Reactive and Proactive Repair

Reactive repair involves fixing equipment or systems only after a failure occurs, leading to unplanned downtime and potentially higher costs due to emergency repairs. Proactive repair emphasizes scheduled maintenance and early detection of issues through inspections and monitoring, reducing the likelihood of unexpected breakdowns. The key difference lies in timing and cost efficiency, with proactive repair focusing on prevention and reactive repair addressing problems post-failure.

Advantages of Reactive Repair

Reactive repair offers the advantage of immediate response to equipment failures, minimizing downtime and restoring functionality quickly. This approach reduces upfront maintenance costs by addressing issues only when they arise, conserving resources for critical repairs. Reactive repair is particularly effective in non-critical systems where operational interruptions have minimal impact on overall productivity.

Advantages of Proactive Repair

Proactive repair enhances equipment reliability by identifying and addressing potential issues before they cause failures, significantly reducing downtime and maintenance costs. This approach optimizes asset lifespan through timely interventions, improving overall operational efficiency and safety. Predictive analytics and condition monitoring technologies enable proactive repair strategies, minimizing unexpected disruptions and maximizing return on investment.

Cost Implications: Reactive vs. Proactive Repair

Reactive repair often incurs higher costs due to unexpected downtime, emergency labor charges, and potential secondary damage requiring extensive fixes. Proactive repair minimizes expenses by scheduling regular maintenance, identifying issues early, and preventing major system failures. Investing in proactive strategies leads to more predictable budgeting and reduced total cost of ownership over time.

Impact on Operational Downtime

Reactive repair often leads to extended operational downtime due to unexpected equipment failures requiring urgent attention. Proactive repair strategies minimize downtime by scheduling maintenance before breakdowns occur, enhancing overall system reliability. Implementing predictive analytics further optimizes repair timing, significantly reducing unplanned operational disruptions.

Choosing the Right Approach for Your Facility

Selecting the right repair strategy is crucial for facility maintenance, balancing reactive repair, which addresses issues after they arise, with proactive repair, designed to prevent failures through scheduled inspections and maintenance. Reactive repair minimizes upfront costs but risks extended downtime and higher emergency expenses, whereas proactive repair emphasizes reliability and long-term savings by anticipating problems before they disrupt operations. Facilities with critical infrastructure benefit from proactive repair to maintain continuous operations, while smaller or less critical sites may find reactive repair more cost-effective depending on their risk tolerance and budget constraints.

Future Trends in Repair Strategies

Future trends in repair strategies emphasize the integration of predictive maintenance technologies such as IoT sensors and AI-driven analytics to shift from reactive repair to proactive repair models. Proactive repair reduces downtime and extends equipment lifespan by identifying potential failures before they occur. The adoption of smart diagnostics and automated repair scheduling will drive efficiency and cost savings in industrial and consumer repair sectors.

Reactive Repair vs Proactive Repair Infographic

jobdiv.com

jobdiv.com